Side cantilever tunnel self-propelled concrete maintenance vehicle

A technology for concrete and maintenance vehicles, which is used in tunnels, tunnel linings, and earth-moving drilling and mining, etc., can solve problems such as the inability to preset and control the curing time and section, affecting the efficiency and quality of spray curing, and the lack of travel and time-controlled switches. , to achieve the effect of saving and protecting water resources, strong passability, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

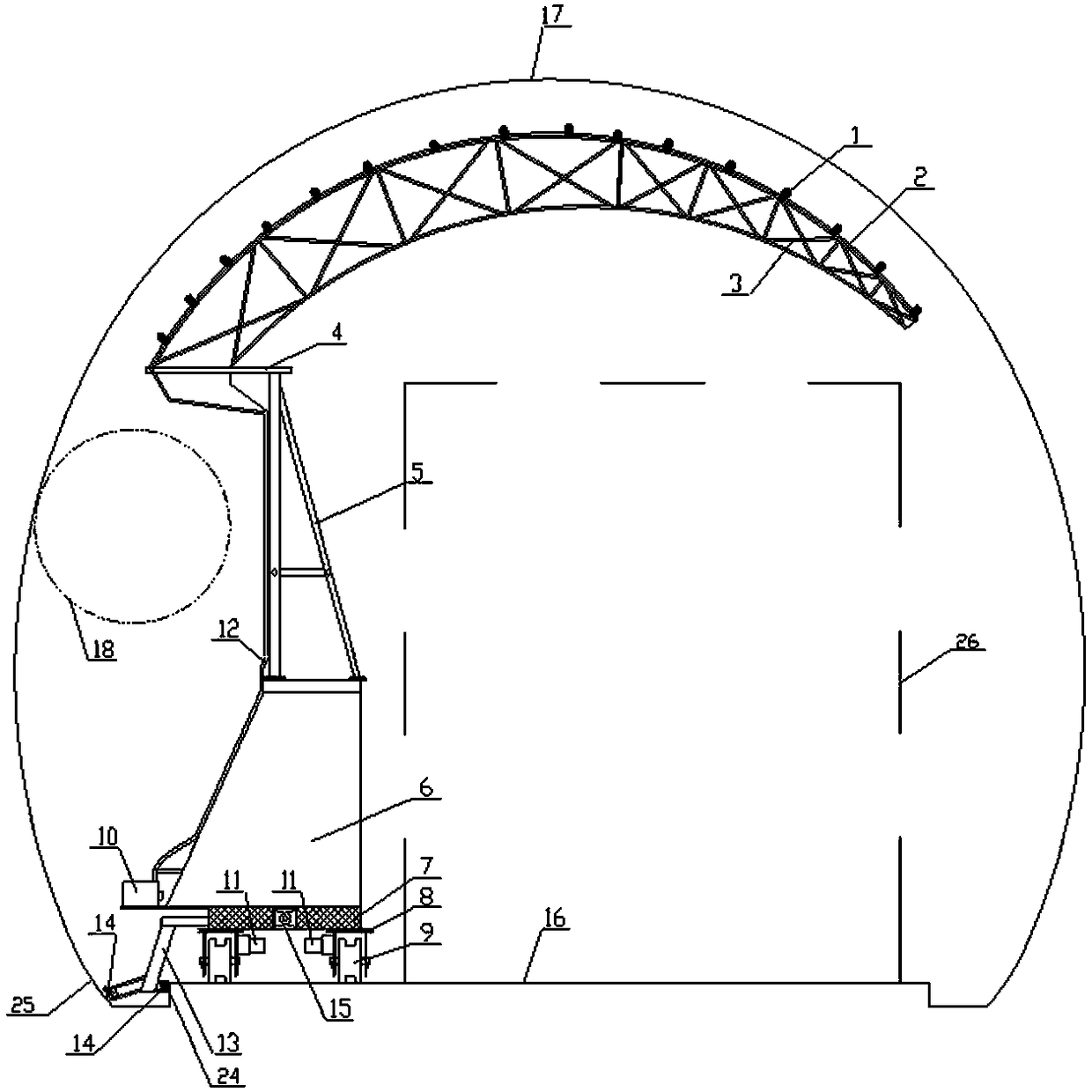

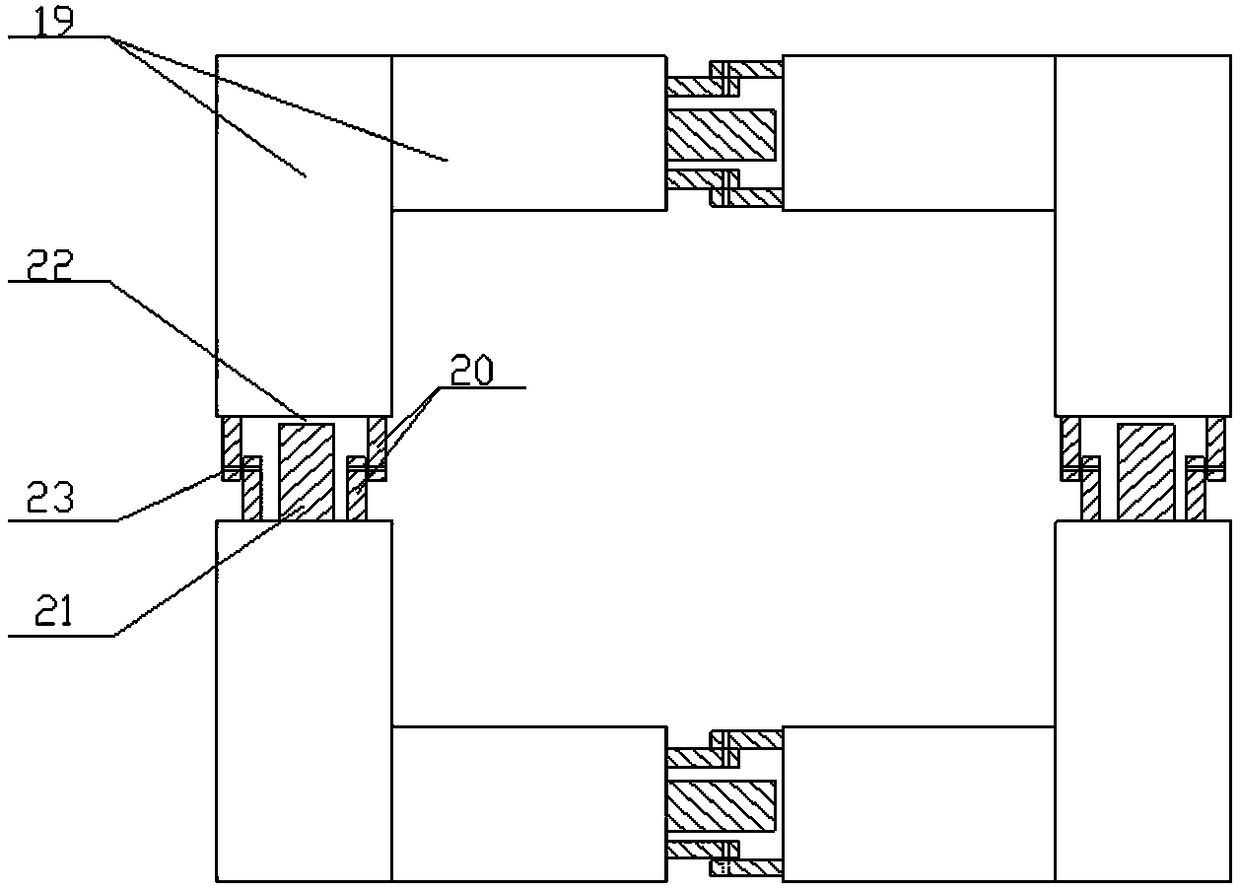

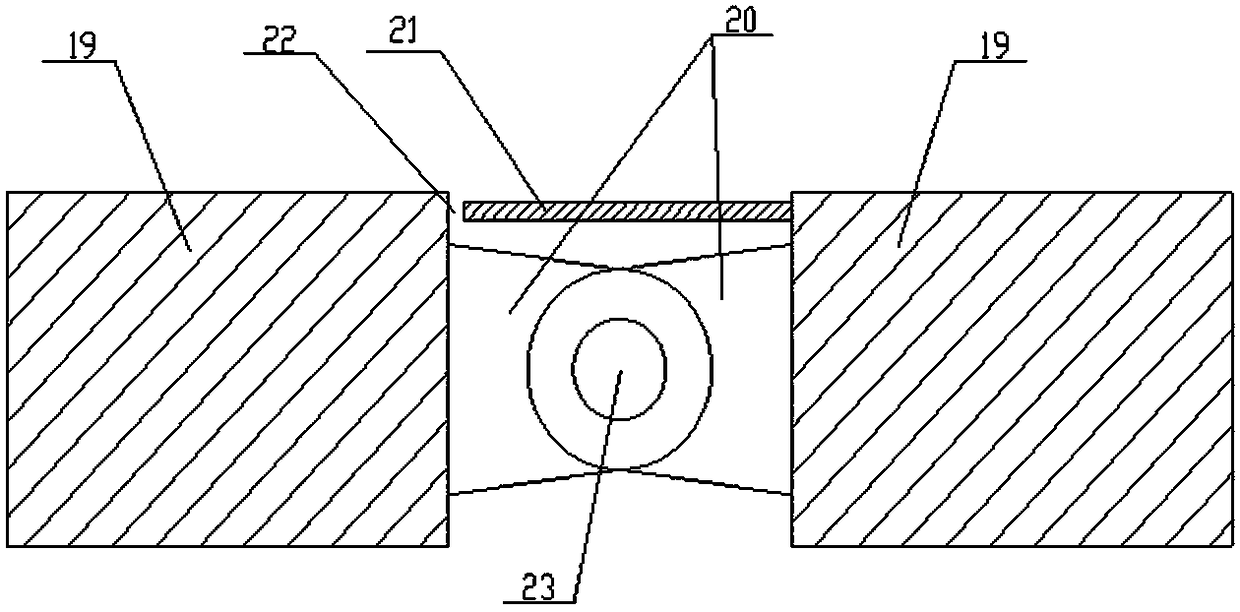

[0028] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0029] Such as Figure 1-3 As shown, the side-standing cantilever type tunnel self-propelled concrete maintenance vehicle of the present invention includes a main frame, a spray maintenance device and a walking device;

[0030] The main frame includes a chassis frame 7, a support frame 5, a support frame pallet 4 and a spray arc arch 3;

[0031] The spray maintenance device includes a self-priming pump 10, a steel water storage tank 6, a water delivery pipe 12, a sprinkler pipe 2 and a nozzle 1;

[0032] The traveling device comprises a traveling rail wheel mounting frame 8, a traveling rail wheel 9 and a reduction motor 11;

[0033] The chassis frame 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com