A combined method of step-by-step focusing-axial mixing-high performance liquid chromatography separation system

A high-performance liquid chromatography and axial mixing technology, which is applied in the joint field of step-by-step focusing-axial mixing-high performance liquid chromatography separation system, can solve the problems of chromatographic peak broadening, splitting, deformation, etc., and achieve low cost, Improve mixing effect, system simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

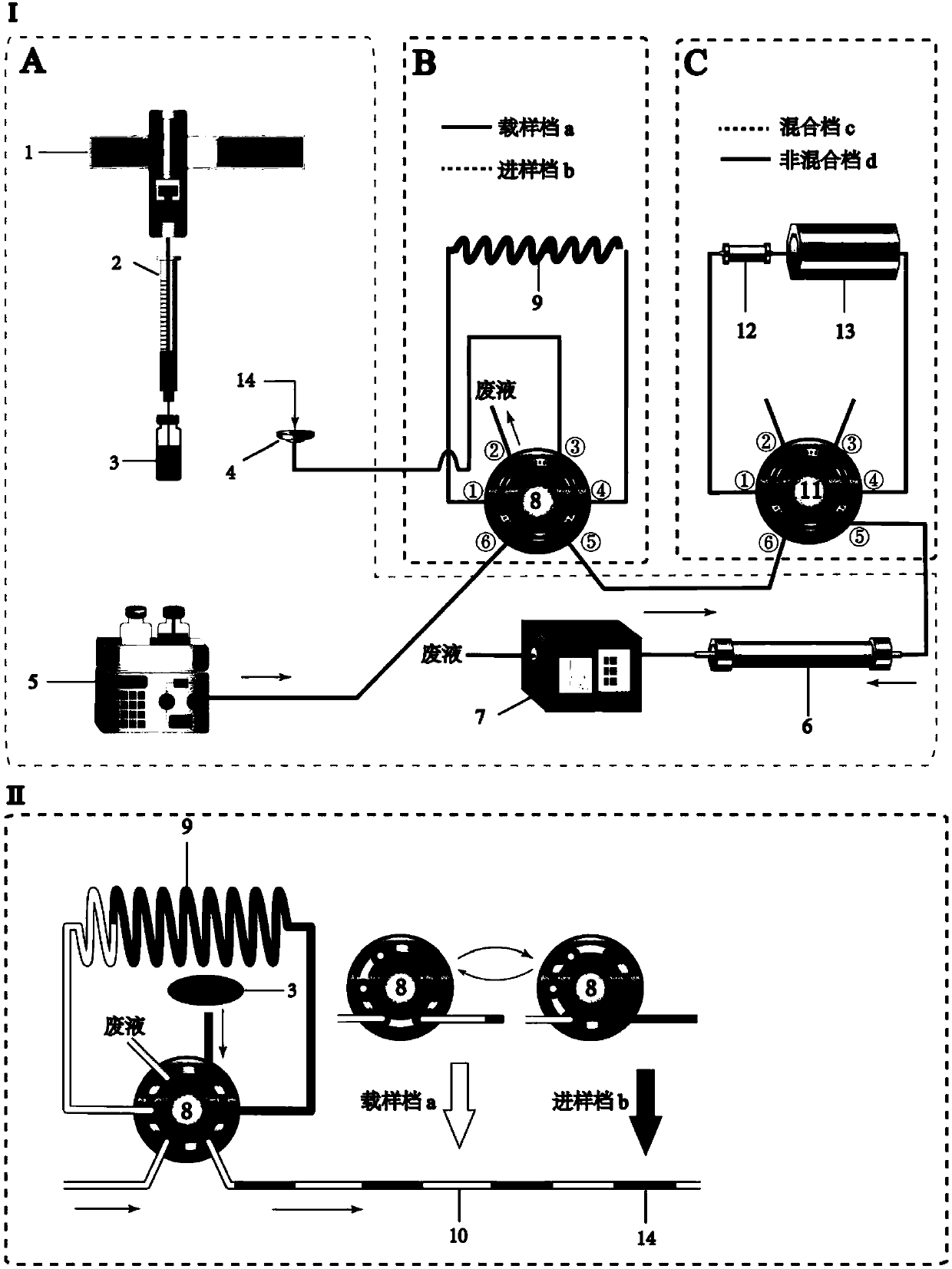

[0029] 1. Composition of step-by-step focusing-axial mixing-high performance liquid chromatography separation system

[0030] see figure 1 In Figure I, the step-by-step focusing-axial mixing-high performance liquid chromatography separation system in this example includes an interconnected step-by-step focusing sampling device B, a switchable axial mixing device C, and a high-performance liquid chromatography device A.

[0031] see figure 1 In Fig. I in the figure, the above-mentioned high-performance liquid chromatography device includes a high-pressure pump 5, an autosampler, a chromatographic column 6 and a detector 7; wherein the autosampler consists of a mechanical arm 1, an autosampler needle 2, a sample bottle 3 and an inlet The sample port 4 is composed of an automatic sample needle 2 that sucks the sample solution 14 into the sample port 4 under the control of the mechanical arm of the automatic sampler 1 .

[0032] see figure 1 In Figure I, the above-mentioned ste...

example 2

[0048] In order to compare the effect of the described method of the invention with the prior art, the inventor has done the following experiments:

[0049] Comparative experiment one

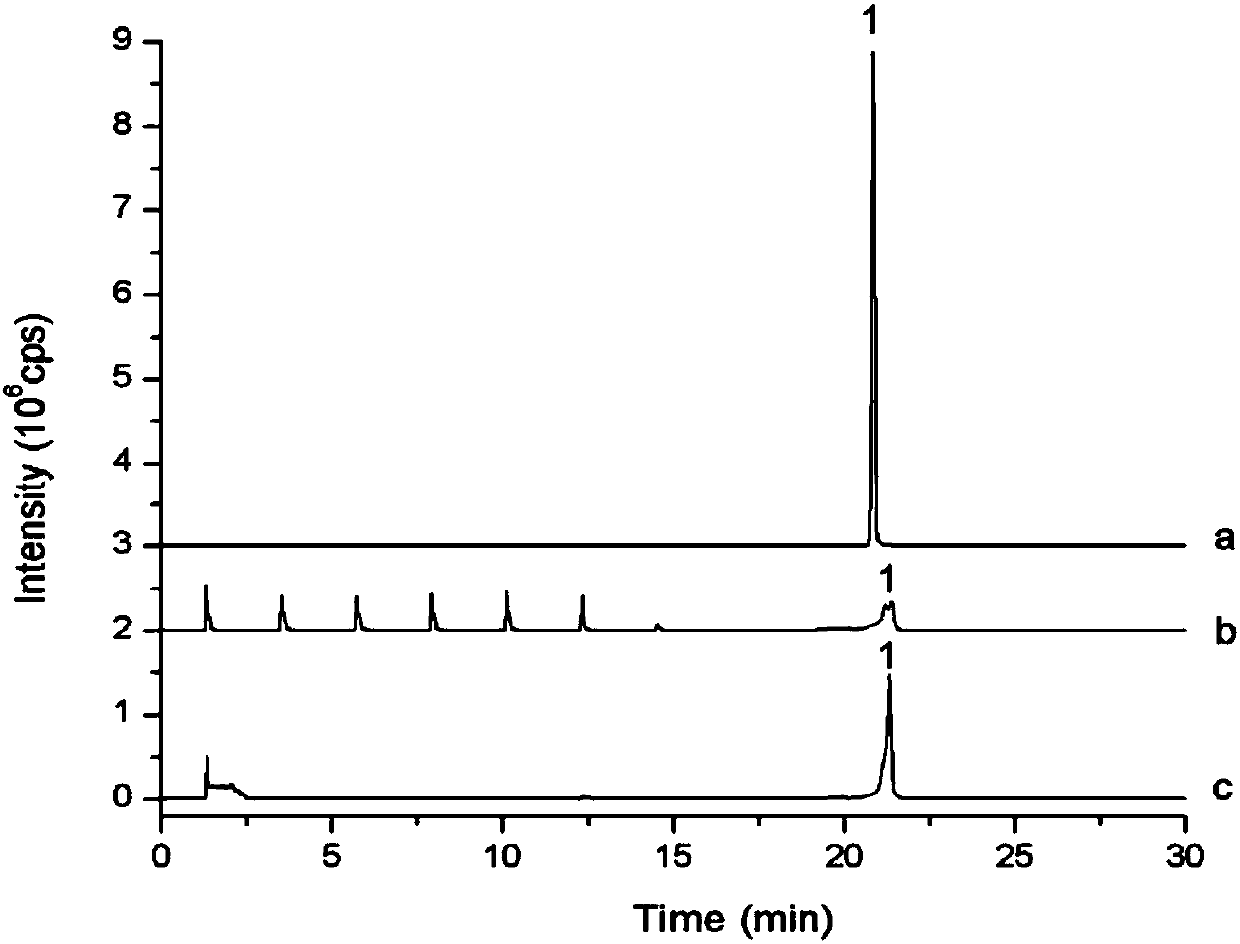

[0050] High performance liquid chromatography-tandem mass spectrometry (i.e. figure 1 The high-efficiency liquid chromatography device in A) detects tetrodotoxin standard solution by conventional sampling method, and mobile phase, eluent and elution gradient and mass spectrometry conditions are all identical with example 1, and the result is as follows figure 2 Shown in c figure.

[0051] Comparative experiment two (equivalent to the method described in the invention patent application with publication number CN103134889A)

[0052] 1. Experimental system: the figure 1 The pre-column 12, mixer 13 and second high-pressure six-way switching valve 11 in the figure I are removed, and the ⑤ port and the ⑥ port of the original second high-pressure six-way switching valve 11 are short-circuited wit...

example 3

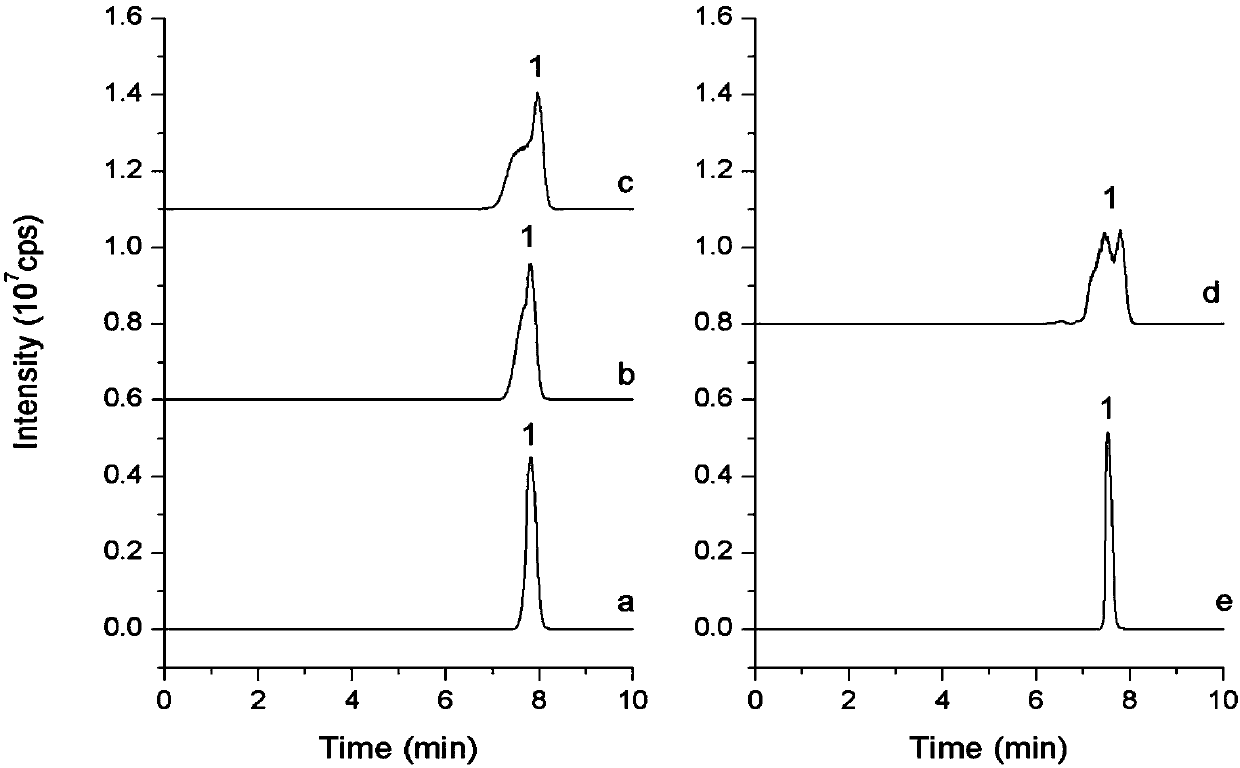

[0057] In order to compare the sample introduction of the method described in the invention with the existing step-by-step focusing method (that is, the method described in the invention patent application with the publication number CN103134889A), the inventor has done the following experiments:

[0058] 1. Use figure 1 In the combined system shown, the injection is increased to 2mL, and the parameters of the combined method are adjusted according to the example, and the results are as follows image 3 Shown in e figure.

[0059] After adjusting the parameters, the specific method is as follows:

[0060] (1) First, according to the mixing ratio of the tetrodotoxin standard solution and the mobile phase acetonitrile, the time length of the first high-pressure six-way switching valve 8 in the sample loading position a is set to 2 min, and the time length in the sample injection position is set to 0.2 min; Set the flow rate of the mobile phase to 1mL / min, and the equilibration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com