Electrical connection structure, closed main busbar and gas-insulated metal-enclosed switchgear

A technology of closed switchgear and electrical connection structure, which is applied to the installation and connection of fully enclosed busbar devices and switchgears, and can solve the problem that there is no heat dissipation structure at the electrical connection structure, the flow capacity of closed busbars is restricted, and the closed busbar cannot conduct electricity normally. and other issues, to achieve the effect of improving heat dissipation efficiency, reducing frictional heat generation, and reducing installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

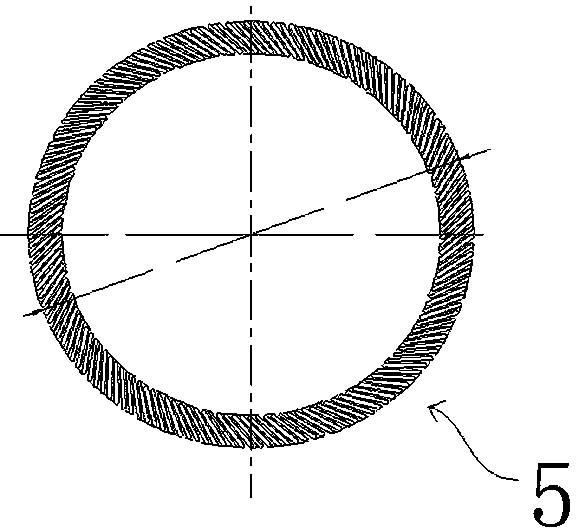

[0048] As another embodiment of the present invention, the spring contact fingers 5 may also be replaced by other forms of contact fingers, such as wristband contact fingers.

[0049] As another embodiment of the present invention, the insulators can also use other forms of insulators instead of pot insulators, as long as the electrical insulation between the electrical connection base and the housing can be realized, but other forms of insulators The effect is not as good as the pot insulator. The pot insulator can increase the creepage distance between the electrical connection seat and the shell, effectively preventing the risk of the insulator being broken down because the creepage distance is too short. The size of the case can be reduced.

[0050] A specific embodiment of the enclosed main busbar of the present invention has the same specific structure as that of the enclosed main busbar in the above-mentioned gas-insulated metal-enclosed switchgear, and will not be repe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com