Water spraying system and waste gas treatment system

A technology of waste gas treatment and water spraying, which is applied in the direction of gas treatment, chemical instruments and methods, and the use of liquid separation agents, etc. It can solve the problems of reducing the service life of equipment, accumulating impurity particles in flue gas, and acidic solutions, so as to save waste , reduce pollution, save water use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

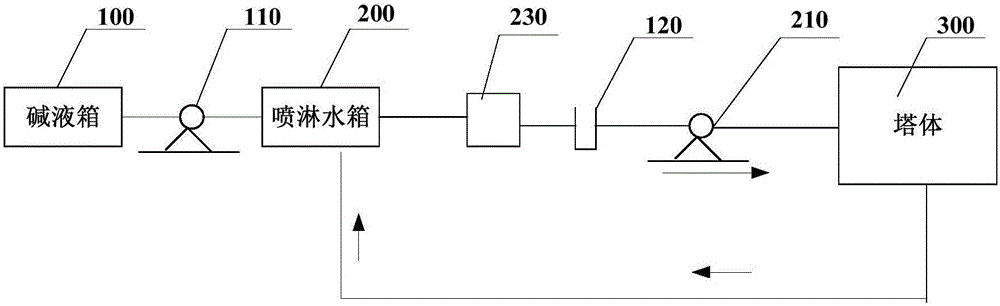

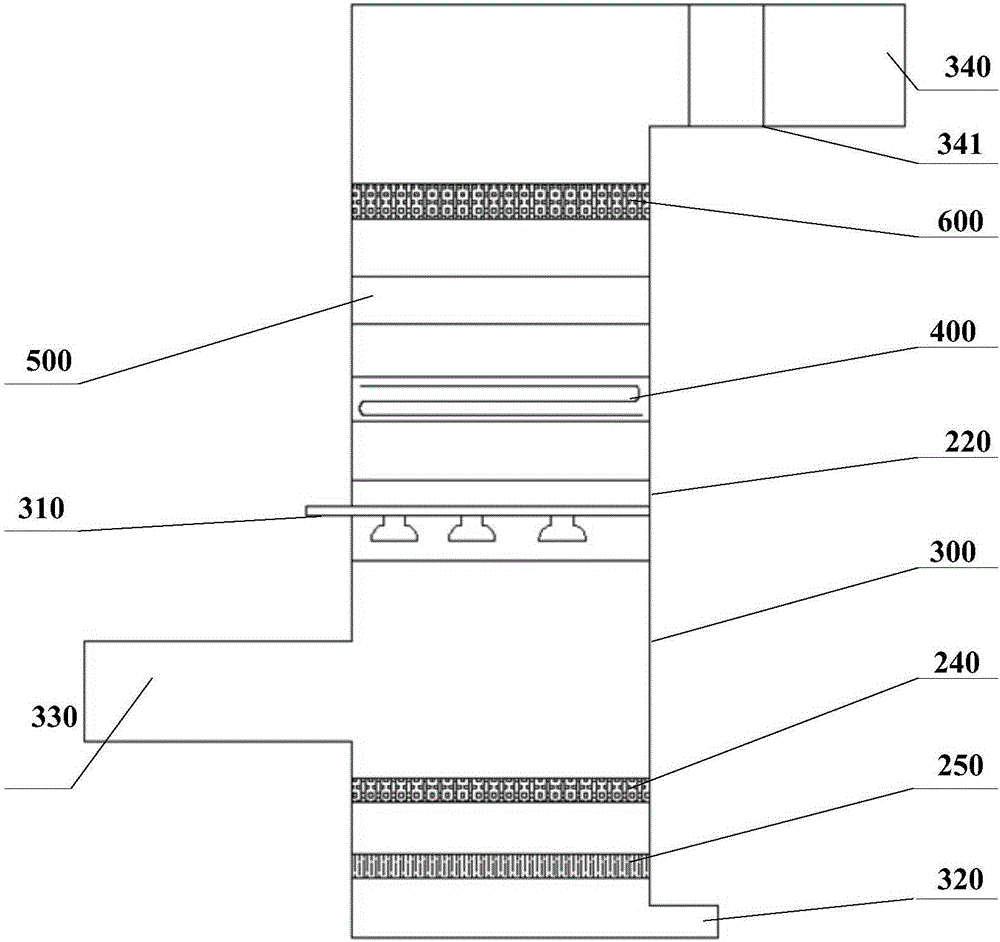

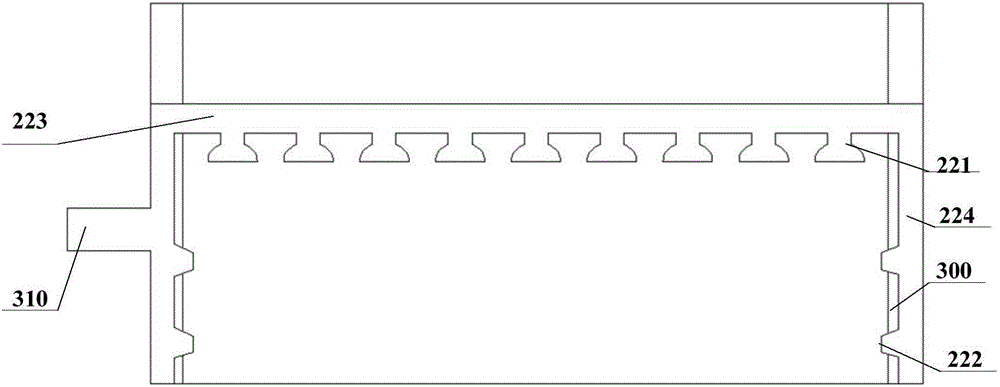

[0038] Such as figure 1 and figure 2 As shown, a water spray system provided in this embodiment includes: lye tank 100, metering pump 110, spray water tank 200, first water pump 210, pH probe 120, nozzle device 220, tower body 300 and control device The lye tank 100, the metering pump 110 and the spray water tank 200 are connected successively; the water outlet of the spray water tank 200, the first water pump 210, the tower body water inlet 310, the tower body water outlet 320 and the spray water tank 200 water inlet are connected successively , form the first circulation system, the pH probe 120 is arranged in the first circulation system; the nozzle device 220 is connected with the tower body water inlet 310, and is arranged in the tower body 300; the smoke inlet 330 of the tower body 300 is arranged on the nozzle device 220 Below, the smoke outlet 340 of the tower body 300 is set above the nozzle device 220; the pH probe 120, the control device and the metering pump 110 ...

Embodiment 2

[0050] Such as figure 2 and Figure 4 As shown, this embodiment provides an exhaust gas treatment system, including: a condensing device, a high-voltage electrostatic device 500, an induced draft fan 341 and a water spray system; the condensing device includes a condensed water tank 400, a second water pump 420, a condensing pipe 410, and a first Two cooling towers 430; the water outlet of the condensed water tank 400, the second water pump 420, the condensation pipe 410, the second cooling tower 430, and the water inlet of the condensed water tank 400 are connected in sequence to form a second circulation system; the condensed water pipe 410 is arranged above the sprinkler device 220 , the high-voltage electrostatic device 500 is arranged between the condensing device and the smoke outlet 340 of the tower body 300 , and the induced draft fan 341 is arranged at the smoke outlet 340 .

[0051] Among them, the working principle of the high-voltage electrostatic device 500 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com