A 360° large component turning device and its working method

A technology for overturning devices and components, applied in hoisting devices, hoisting devices, etc., which can solve the problems of hidden dangers to workers' personal safety, increased production costs, and low risk factors, and achieve simple and reliable overturning, reduced work intensity, and reduced labor costs. intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

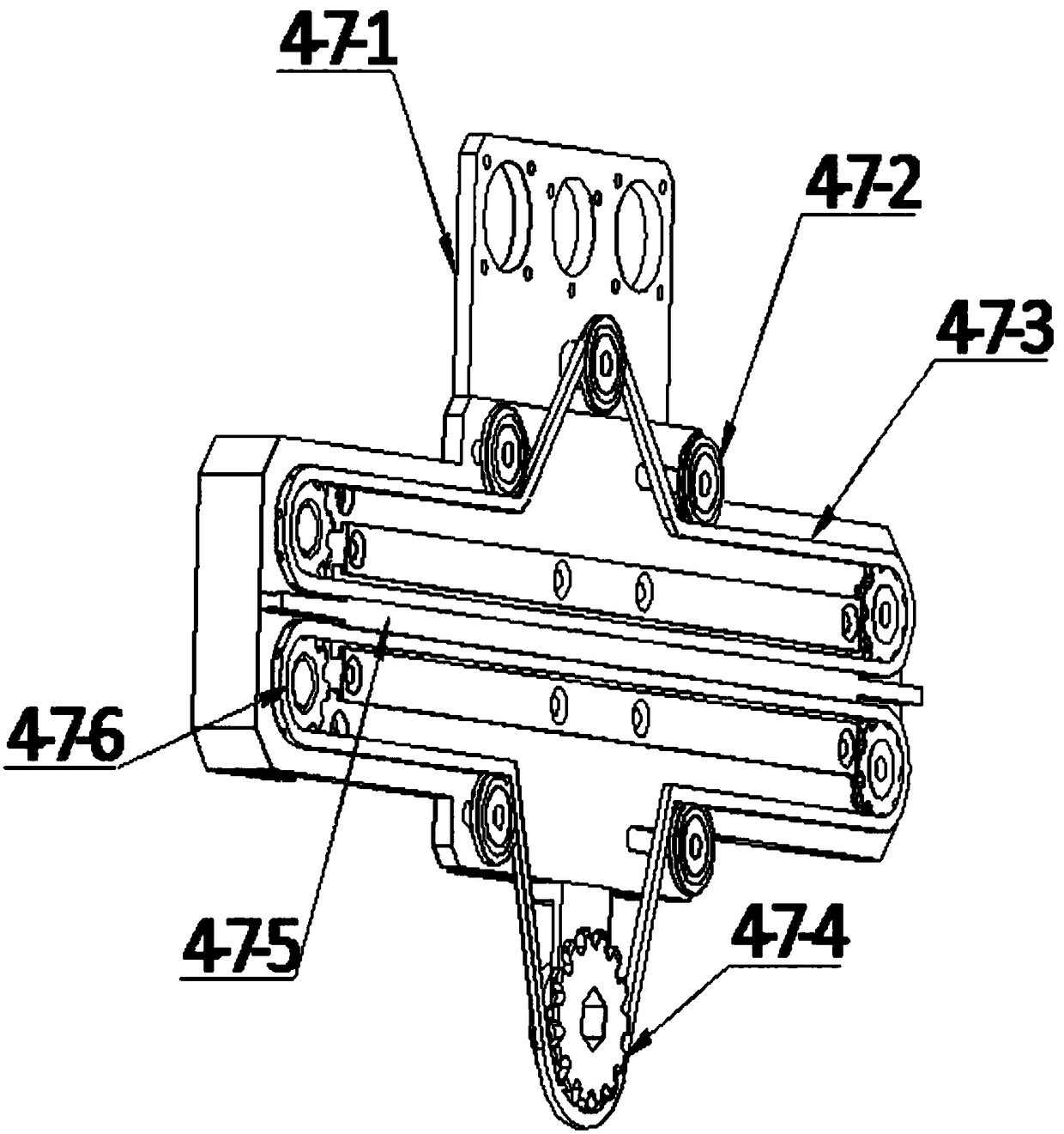

[0047] Manufacture tensioning wheel 4-7-2 of the present invention according to the following steps, and in parts by weight:

[0048] Step 1: Add 1890 parts of ultrapure water with a conductivity of 5.54μS / cm into the reactor, start the stirrer in the reactor at a speed of 126rpm, start the heating pump, and raise the temperature in the reactor to 105°C; add in sequence Benzyl 6-formylpyridin-3-ylcarbamate 130 parts, 6,7-dihydro-2-methyl-4-oxo-1H-pyrrolo[3,2-c]pyridine-5( 4h)-195 parts of tert-butyl carboxylate, 3-hydroxy-4-[(2-methyl-5-nitrophenyl)azo]-N-(2-methylphenyl)-2-naphthylmethyl 115 parts of amide, stirred until completely dissolved, adjusted the pH value to 2.1, adjusted the speed of the agitator to 162rpm, the temperature was 130°C, and the esterification reaction was carried out for 18 hours;

[0049] Step 2: Take 125 parts of tert-butyl 1-(3-nitrobenzyl)piperidin-4-ylcarbamate, 3-(N,N-dimethoxyethyl)amino-4-methoxy 87 parts of acetanilide were pulverized, and t...

Embodiment 2

[0054] Manufacture tensioning wheel 4-7-2 of the present invention according to the following steps, and in parts by weight:

[0055]Step 1: Add 3450 parts of ultrapure water with a conductivity of 6.86μS / cm into the reactor, start the agitator in the reactor at a speed of 166rpm, start the heating pump, and raise the temperature in the reactor to 128°C; add in sequence 177 parts of benzyl 6-formylpyridin-3-ylcarbamate, 6,7-dihydro-2-methyl-4-oxo-1H-pyrrolo[3,2-c]pyridine-5( 4h)-240 parts of tert-butyl carboxylate, 3-hydroxy-4-[(2-methyl-5-nitrophenyl)azo]-N-(2-methylphenyl)-2-naphthylmethyl 192 parts of amide, stir until completely dissolved, adjust the pH value to 6.5, adjust the speed of the agitator to 228rpm, the temperature is 165°C, and the esterification reaction is 28 hours;

[0056] Step 2: Take 208 parts of tert-butyl 1-(3-nitrobenzyl)piperidin-4-ylcarbamate, 3-(N,N-dimethoxyethyl)amino-4-methoxy 121 parts of acetanilide were pulverized, and the particle size of t...

Embodiment 3

[0060] Manufacture tensioning wheel 4-7-2 of the present invention according to the following steps, and in parts by weight:

[0061] Step 1: Add 2670 parts of ultrapure water with a conductivity of 6.21μS / cm into the reactor, start the stirrer in the reactor at a speed of 146rpm, start the heating pump, and raise the temperature in the reactor to 116°C; add in sequence 153 parts of benzyl 6-formylpyridin-3-ylcarbamate, 6,7-dihydro-2-methyl-4-oxo-1H-pyrrolo[3,2-c]pyridine-5( 4h)-217 parts of tert-butyl carboxylate, 3-hydroxy-4-[(2-methyl-5-nitrophenyl)azo]-N-(2-methylphenyl)-2-naphthylmethyl 153 parts of amide, stir until completely dissolved, adjust the pH value to 4.3, adjust the speed of the agitator to 195rpm, the temperature is 147°C, and the esterification reaction takes 23 hours;

[0062] Step 2: Take 166 parts of tert-butyl 1-(3-nitrobenzyl)piperidin-4-ylcarbamate, 3-(N,N-dimethoxyethyl)amino-4-methoxy 104 parts of acetanilide were pulverized, and the particle size o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com