A method for continuous production of sodium fluoride

A sodium fluoride and sodium fluoride-containing technology, applied in the direction of alkali metal fluoride, silicon oxide, silicon dioxide, etc., can solve the problems of poor quality sodium fluoride, high labor intensity, high raw material consumption, etc., and achieve low raw material consumption , reduce labor intensity, the effect of excellent product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

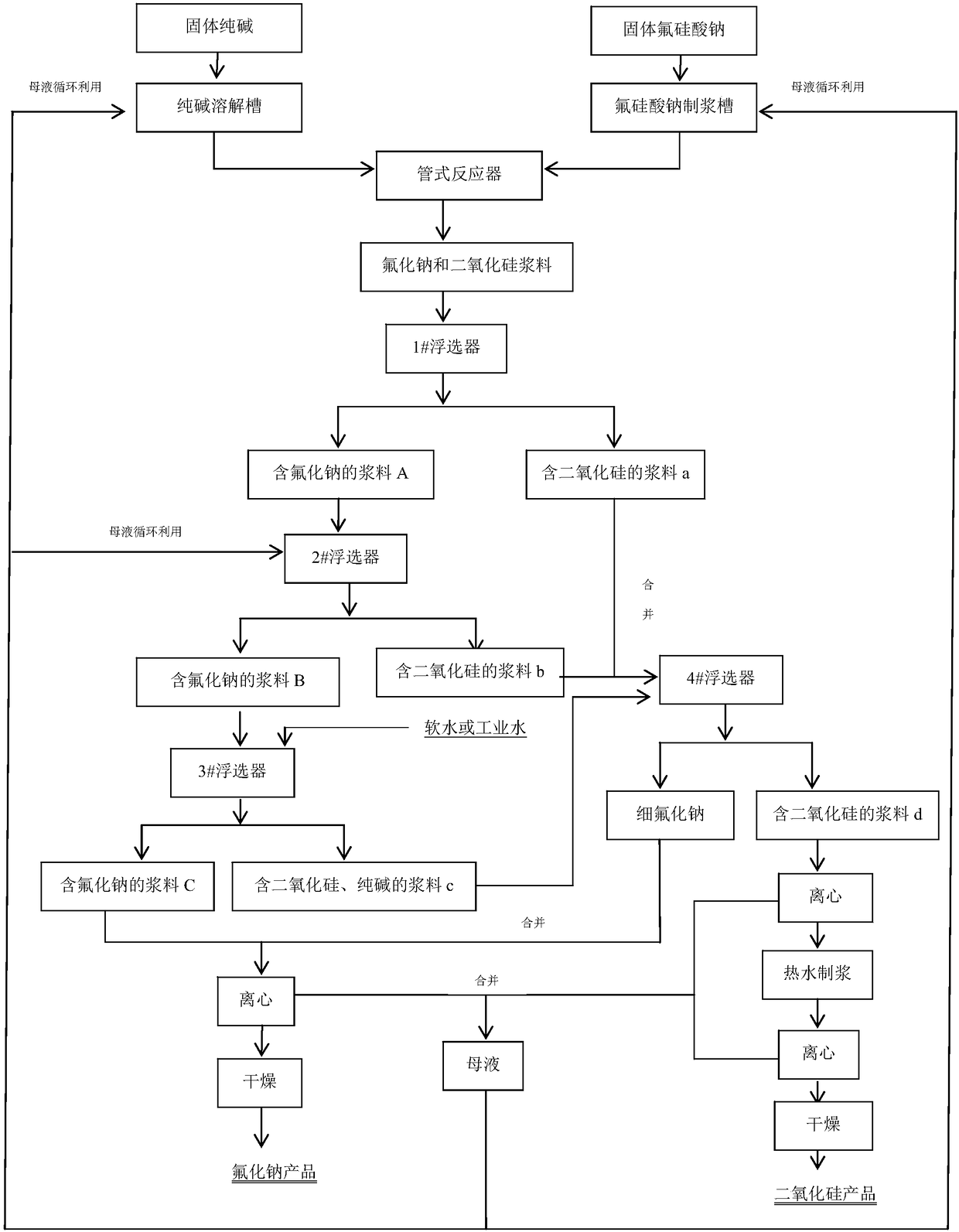

[0037] The process block diagram of the continuous production of sodium fluoride in this embodiment is as follows figure 2 As shown, the specific steps are as follows:

[0038](1) Put the solid soda ash into the silo, put it into the dissolving tank at a speed of 1000kg / h with a screw conveyor, continuously add the mother liquor of the subsequent process into the dissolving tank, add the flow rate of 3600-4000kg / h, and heat it with steam under stirring Dissolve the soda ash at 75°C-78°C, keep the concentration (mass fraction) of the dissolved soda ash solution at 20-22%, and pump it continuously into the tubular reactor;

[0039] (2) Put solid sodium fluorosilicate (water content 6%) into the silo, add it into the pulping tank at a speed of 900kg / h with a screw conveyor, continuously add the mother liquor of the subsequent process in the pulping tank, and add the flow rate 2400-2600kg / h, heat to 75°C-78°C with steam under stirring, keep the solid-liquid ratio (mass fraction ...

Embodiment 2

[0048] The process block diagram of the continuous production of sodium fluoride in this embodiment is as follows figure 2 As shown, the specific steps are as follows:

[0049] (1) Put the solid soda ash into the silo, put it into the dissolving tank at a speed of 1000kg / h with a screw conveyor, continuously add the mother liquor of the subsequent process into the dissolving tank, add the flow rate of 3600-4000kg / h, and heat it with steam under stirring Dissolve the soda ash at 80°C-85°C, keep the concentration (mass fraction) of the dissolved soda ash solution at 26-28%, and pump it continuously into the tubular reactor;

[0050] (2) Put solid sodium fluorosilicate (water content 6%) into the silo, add it into the pulping tank at a speed of 900kg / h with a screw conveyor, continuously add the mother liquor of the subsequent process in the pulping tank, and add the flow rate 2400-2600kg / h, heat it with steam to 80°C-85°C under stirring, keep the solid-liquid ratio (mass fract...

Embodiment 3

[0059] The process block diagram of the continuous production of sodium fluoride in this embodiment is as follows figure 2 As shown, the specific steps are as follows:

[0060] (1) Put the solid soda ash into the silo, put it into the dissolving tank at a speed of 1000kg / h with a screw conveyor, continuously add the mother liquor of the subsequent process into the dissolving tank, add the flow rate of 3600-4000kg / h, and heat it with steam under stirring Dissolve the soda ash at 60°C-65°C, keep the concentration (mass fraction) of the dissolved soda ash solution at 23-25%, and pump it continuously into the tubular reactor;

[0061] (2) Put solid sodium fluorosilicate (water content 6%) into the silo, add it into the pulping tank at a speed of 900kg / h with a screw conveyor, continuously add the mother liquor of the subsequent process in the pulping tank, and add the flow rate 2400-2600kg / h, heat to 60°C-65°C with steam under stirring, keep the solid-liquid ratio (mass fraction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com