A method for preparing lead sulfide superfine powder by using waste lead-acid battery lead paste

A lead-acid battery, lead sulfide technology, applied in the direction of lead sulfide, battery recycling, recycling technology, etc., can solve the problems of low added value of recycled products, waste of resources, environment, pollution, etc., and achieve proper resource treatment and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

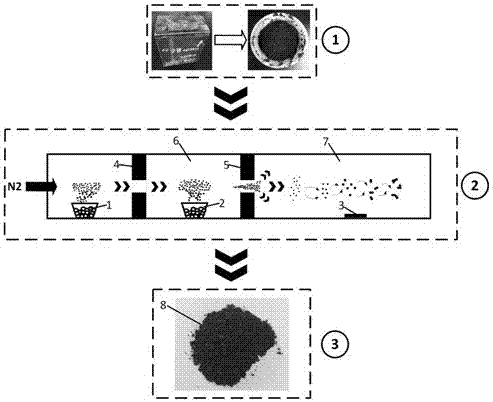

[0033]Firstly, the waste lead-acid batteries are crushed and screened by the conventional process, and the obtained lead paste is dried in an electronic temperature-adjusting electric furnace at 150°C, and then ground into particles with a particle size of 0.05~0.15mm, and then 30g of lead paste and 6g of carbon are weighed. The powder is fully mixed, and the mixed material is loaded into the heating chamber of the tube furnace with a crucible, and the two ends of the heating chamber are isolated with a pipe plug with holes. 10cm from the front end. At the rear end of the pipe plug with holes at the other end of the heating chamber, that is, a quartz plate is placed at a place 60 cm away from the pipe plug in the condensation chamber as a collection base. For details on the location of the crucible and collection base, see figure 1 shown. After the tube furnace is sealed, start the vacuum pump group to exhaust the air in the furnace, so that the vacuum in the furnace is betw...

Embodiment 2

[0035] Firstly, the waste lead-acid batteries are crushed and screened by the conventional process, and the obtained lead paste is dried in an electronic temperature-regulated electric furnace at 150°C, and then ground into particles with a particle size of 0.05~0.15mm, and then 30g of lead paste and 6g of carbon are weighed. The powder is fully mixed, and the mixed material is loaded into the heating chamber of the tube furnace with a crucible, and the two ends of the heating chamber are isolated with a pipe plug with holes. 10cm from the front end. At the rear end of the pipe plug with holes at the other end of the heating chamber, that is, a quartz plate is placed at a place 60 cm away from the pipe plug in the condensation chamber as a collection base. For details on the location of the crucible and collection base, see figure 1 shown. After the tube furnace is sealed, start the vacuum pump group to exhaust the air in the furnace, so that the vacuum degree in the furnace...

Embodiment 3

[0037] Firstly, the waste lead-acid batteries are crushed and screened by the conventional process, and the obtained lead paste is dried in an electronic temperature-regulated electric furnace at 150°C, and then ground into particles with a particle size of 0.05~0.15mm, and then 30g of lead paste and 6g of carbon are weighed. The powder is fully mixed, and the mixed material is loaded into the heating chamber of the tube furnace with a crucible, and the two ends of the heating chamber are isolated with a pipe plug with holes. 10cm from the front end. At the rear end of the pipe plug with holes at the other end of the heating chamber, that is, a quartz plate is placed at a place 60 cm away from the pipe plug in the condensation chamber as a collection base. For details on the location of the crucible and collection base, see figure 1 shown. After the tube furnace is sealed, start the vacuum pump group to exhaust the air in the furnace, so that the vacuum degree in the furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com