Modular multi-tube Fenton fluidized bed reactor

A fluidized bed reactor and tube-and-tube technology, which is applied to chemical instruments and methods, water distribution pipes, and water treatment of special compounds, etc., can solve the problem of lower mixing uniformity between chemicals and wastewater, insufficient contact between fillers and wastewater, and poor reaction efficiency. Drop and other problems, to achieve the effect of easy processing and manufacturing and on-site combination, avoid short flow, and enhance uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

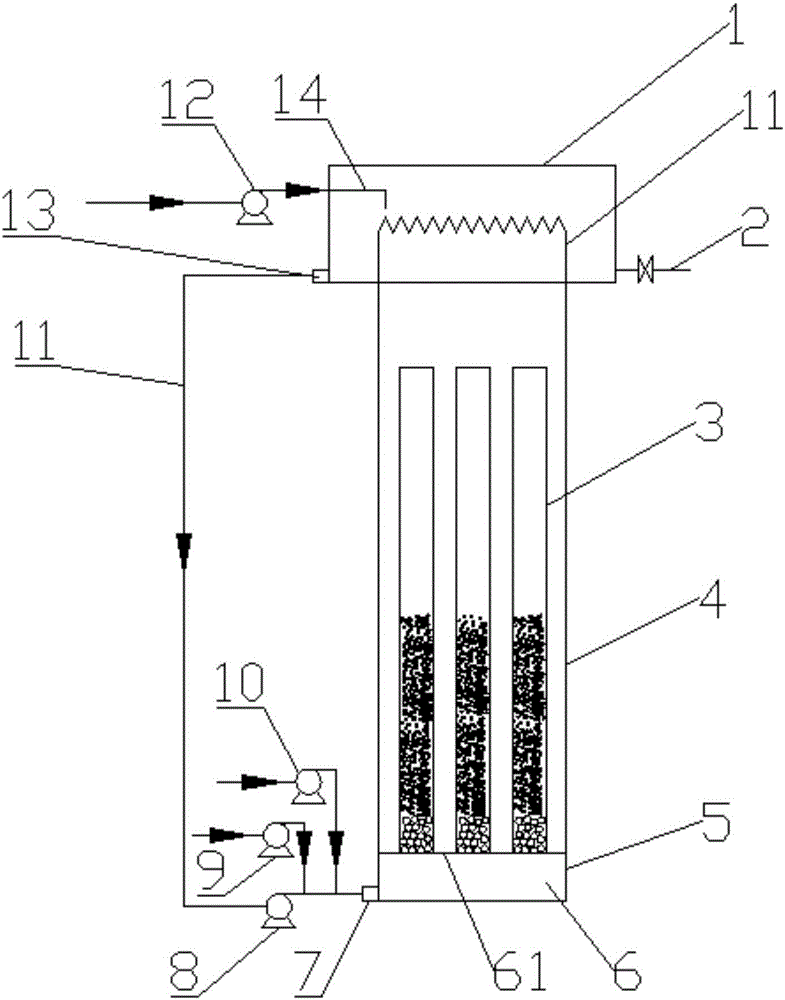

[0053] The modular tubular Fenton fluidized bed reactor includes a vertically arranged fluidized bed cylinder 4, an end cover is provided at the lower end of the fluidized bed cylinder 4, and a The first water inlet 7 is not provided with an end cover at the upper end as the first water outlet.

[0054] A water distributor 5 is also included, and the water distributor 5 is arranged at the bottom end inside the fluidized bed cylinder 4 , and the water inlet of the water distributor 5 communicates with the first water inlet 7 .

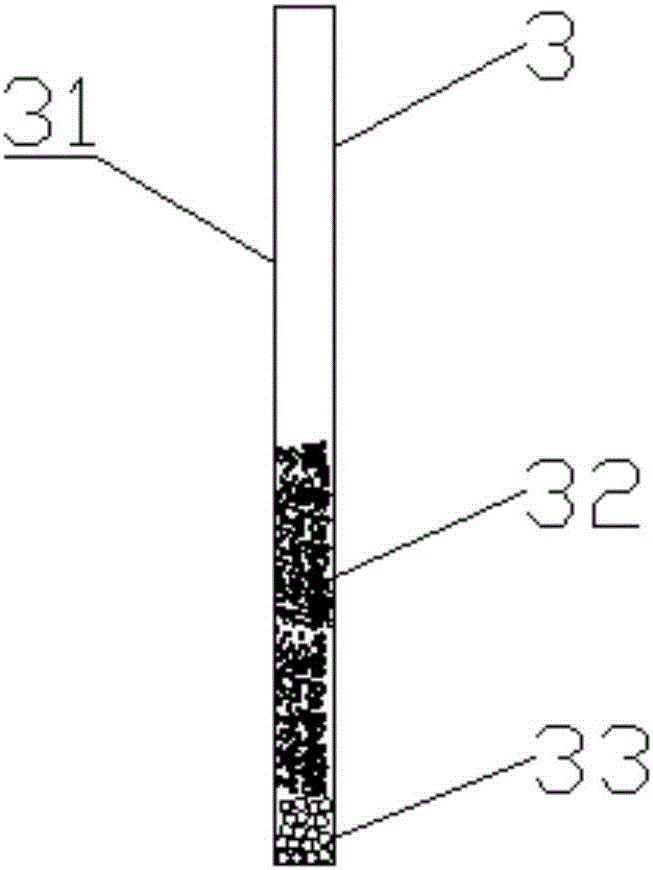

[0055] It also includes a plurality of tubular fluidized bed modules 3, the tubular fluidized bed modules 3 are arranged inside the fluidized bed cylinder 4, and the bottom of the tubular fluidized bed modules 3 and the water outlet of the water distributor 5 connected.

[0056] During operation, the sewage, ferrous sulfate solution, and hydrogen peroxide enter the water distributor 5 from the first water inlet 7 using a water pump, and then enter the ...

Embodiment 2

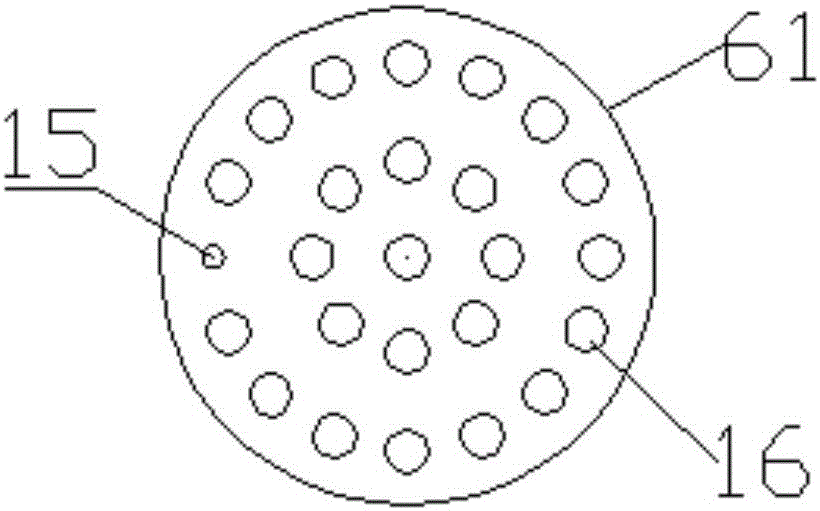

[0059] In this embodiment, the difference from Embodiment 1 is that the water distributor 5 includes a circular baffle 61 , and the baffle 61 is fixedly arranged at a lower position inside the fluidized bed cylinder 4 . In this way, the baffle plate 61 and the bottom end cover of the fluidized bed cylinder 4 form a mixing chamber 6 .

[0060] The baffle plate 61 is provided with a number of water outlet holes, and a water distribution filter head 16 is installed on the water outlet hole, and the water distribution filter head 16 extends into the bottom of the tubular fluidized bed module 3 . In this embodiment, assuming that the number of shell-and-tube fluidized bed modules 3 is three, then the number of outlet holes on the baffle plate 61 is also three.

[0061]The mixing chamber 6 and the baffle 61 are integrally used as the water distributor 5, the height of the first water inlet 7 on the side wall is between the bottom of the baffle 61 and the fluidized bed cylinder 4, th...

Embodiment 3

[0065] On the basis of Example 2, this embodiment also includes a sedimentation tank 1 and an outlet weir 2, the outlet weir 2 is arranged inside the sedimentation tank 1, and the upper end of the fluidized bed cylinder 4 is fixedly connected to the lower end of the outlet weir 2. Such arrangement connects the fluidized bed cylinder body 4 with the water outlet weir 2, and the water in the fluidized bed cylinder body 4 can enter the sedimentation tank 1 through the water outlet weir 2.

[0066] First, set the sedimentation tank 1 and the outlet weir 2 on the ground, and set the fluidized bed cylinder 4 below the ground, so as to avoid the construction of other structures to support the sedimentation tank. Those skilled in the art can also set up other structures to support the sedimentation tank 1 according to the actual situation.

[0067] The sedimentation tank 1 is provided with a circulating water outlet 13 and a second water outlet, and both the circulating water outlet a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com