Beta-type similar high-strength and high-tenacity titanium alloy

A tough titanium alloy and titanium alloy technology, applied in the field of near-beta type high-strength and high-toughness titanium alloy and titanium alloy, to achieve the effects of excellent performance, improved strength and toughness indicators, and good toughness-plastic matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation process of the near-β type high-strength and high-toughness titanium alloy in this application is as follows:

[0030] Alloy raw materials are configured according to the content range of the above-mentioned alloy elements and the requirements of molybdenum equivalent and aluminum equivalent. Raw materials can be selected from sponge titanium, Al-85V master alloy, Al-80Mo master alloy, Al-70Nb master alloy, pure aluminum and pure chromium.

[0031] The ingredients are mixed according to the ratio, pressed into electrodes, and smelted in a vacuum consumable electric arc furnace for 3 times to obtain alloy ingots. After the ingot is peeled off, the riser and tail are cut, the billet forging is carried out, and the intermediate multiple fires are deformed, and finally forged or rolled bars, plates, forgings and other semi-finished products of titanium alloys of this application, these alloys after appropriate heat treatment Semi-finished products can be man...

Embodiment 1

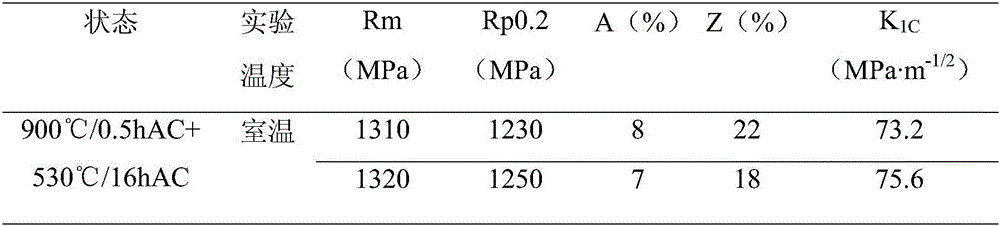

[0034] Ingredients by weight percentage, Al: 3%, Mo: 5%, V: 5%, Cr: 4%, Nb: 2%, and the balance is titanium. The raw materials are sponge titanium, Al-85V master alloy, Al-80Mo master alloy, Al-70Nb master alloy, pure aluminum and pure chromium. The ingredients are mixed according to the ratio, pressed into electrodes, and smelted in a vacuum consumable electric arc furnace for 3 times to obtain alloy ingots. After peeling the ingot and cutting the riser and tail, the heating temperature for blank forging is about 1150°C, and the heating temperature for repeated thickening and elongation is about 900°C, and the forging is 35mm×75mm×600mm square Great, see Table 1 for the data.

[0035]

Embodiment 2

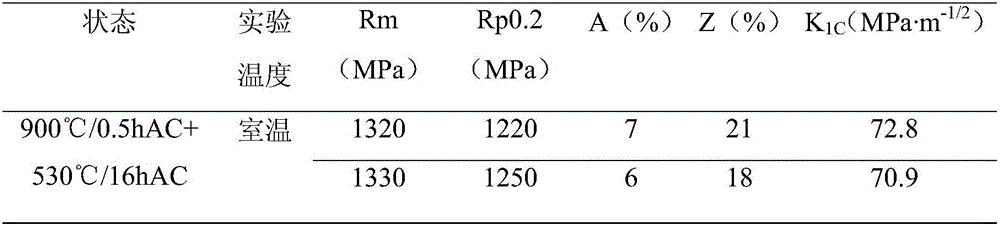

[0037] Ingredients by weight percentage, Al: 3%, Mo: 6%, V: 5%, Cr: 3%, Nb: 2%, and the balance is titanium. The raw materials are sponge titanium, Al-85V master alloy, Al-80Mo master alloy, Al-70Nb master alloy, pure aluminum and pure chromium. The ingredients are mixed according to the ratio, pressed into electrodes, and smelted in a vacuum consumable electric arc furnace for 3 times to obtain alloy ingots. After peeling the ingot and cutting the riser and tail, the heating temperature for blank forging is about 1150°C, and the heating temperature for repeated thickening and elongation is about 900°C, and the forging is 35mm×75mm×600mm square Great, see Table 2 for the data.

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com