A fully assembled village and town dwelling compound wall structure system and its construction method

A construction method and composite wall technology, applied in the direction of walls, building types, building components, etc., can solve problems such as the lack of effective guarantee of building quality, no insulation treatment of buildings, and dust pollution of the environment, so as to achieve the benefits of integrity and Effects of shock resistance, increased friction, and low environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

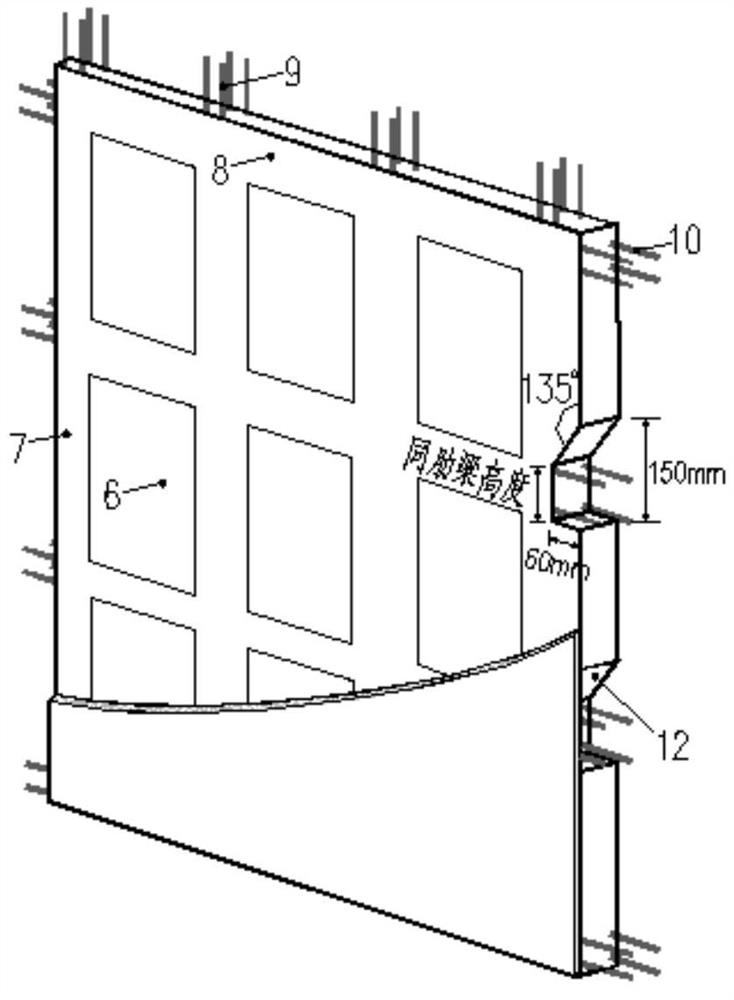

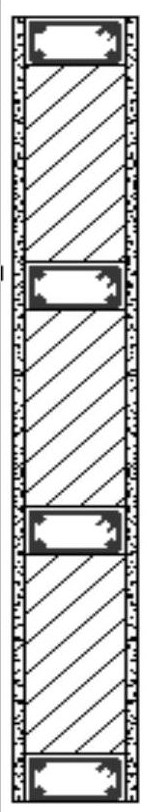

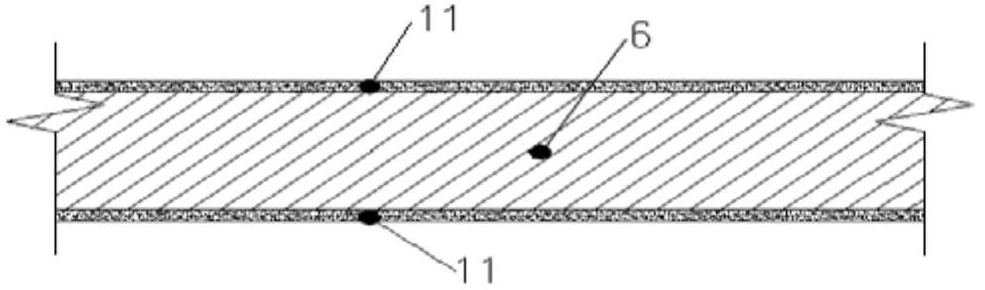

[0061] The fully assembled composite wall structure system of the present invention includes: prefabricated building main load-bearing components (prefabricated inverted trapezoidal trough composite wall, prefabricated truss reinforced concrete composite floor, prefabricated reinforced concrete composite beam, etc.) and prefabricated auxiliary components (prefabricated reinforced concrete stairs, prefabricated reinforced concrete balconies, prefabricated reinforced concrete canopies, prefabricated reinforced concrete air-conditioning panels, prefabricated composite parapets, etc.). Construction site: Only reinforced concrete connecting columns 44 with small cross-sections need to be poured between the wall panels; only reinforced concrete restrained hidden beams 45 with small cross-sections need to be poured between the wall panels and laminated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com