Roadway surrounding rock closed protection method

A technology of surrounding rock and roadway, applied in the field of roadway support, can solve the problems of poor bonding, high jet rebound, poor compactness, etc., restore the overall continuity and improve the effect of crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the following specific examples will further describe the present invention in detail. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

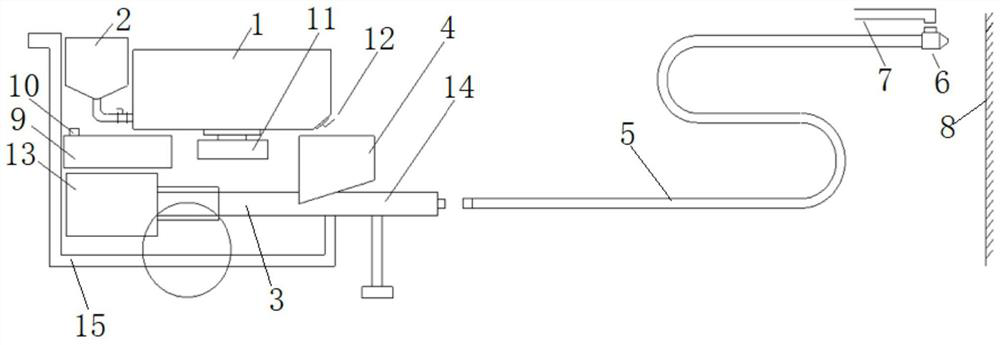

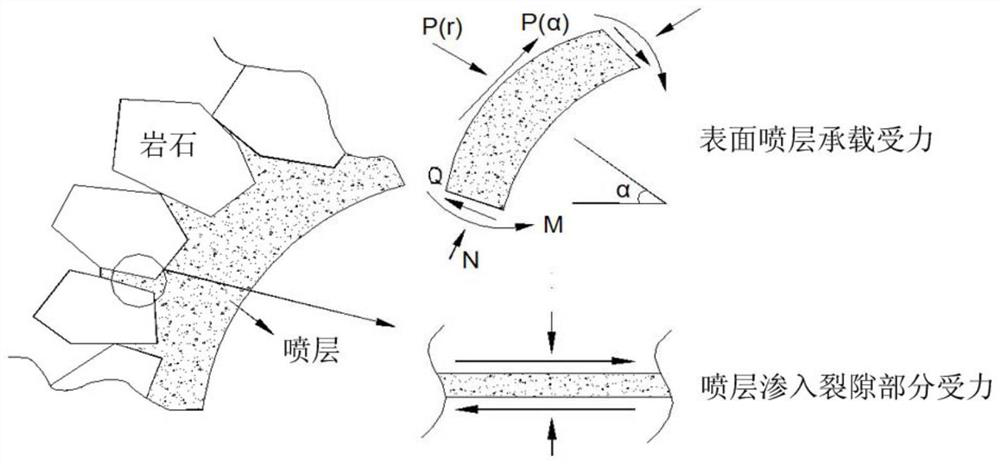

[0036]The invention provides a roadway surrounding rock sealing and protection method. Before the integrity of the roadway surrounding rock is damaged, that is, after the roadway is excavated and the roof is supported for 3-4 cycles, the exposed surrounding rock of the roadway is sprayed with a thin layer of slurry. Spraying; thin-layer spraying slurry forms a continuous and dense sealing layer on the exposed surrounding rock surface of the roadway; 1-2 hours after the thin-layer spraying slurry is sprayed, the bolt cable construction is carried out on the sealing protective slurry coating.

[0037] Among them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com