Method for preparing tubular asymmetrical mixed conductor compact film

A mixed conductor, asymmetric technology, used in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. The effect of compactness problem, good repeatability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

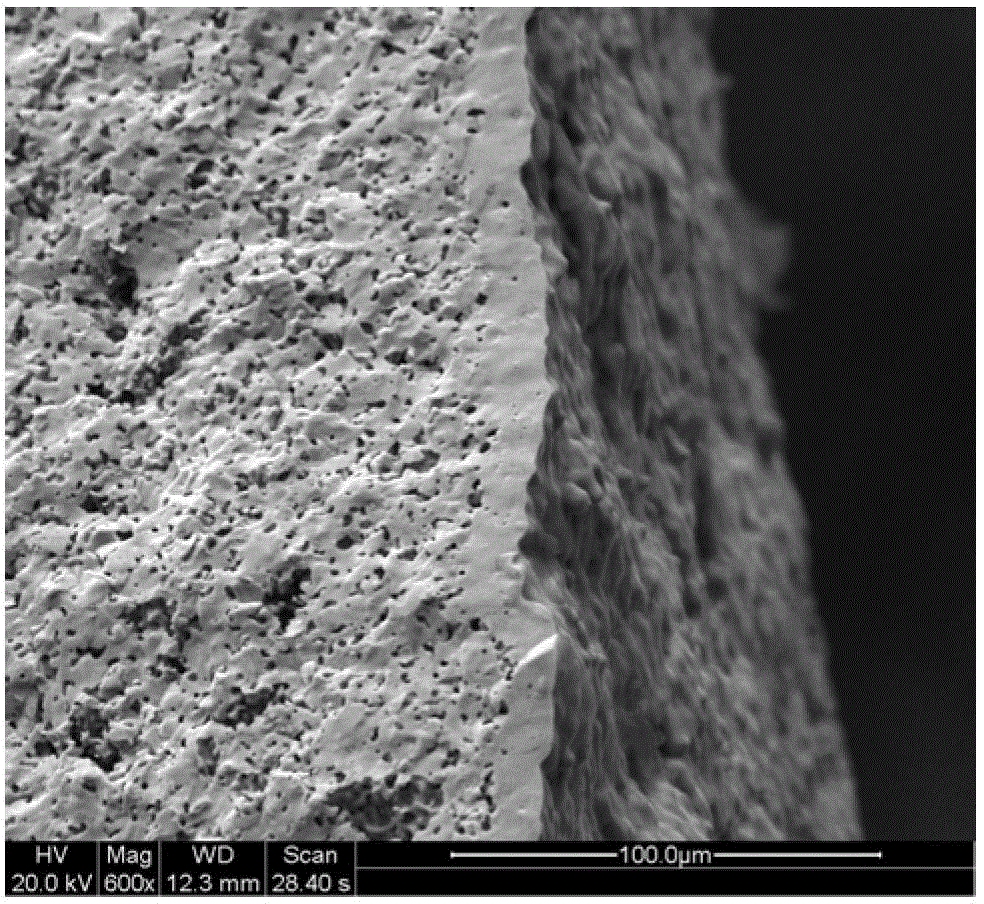

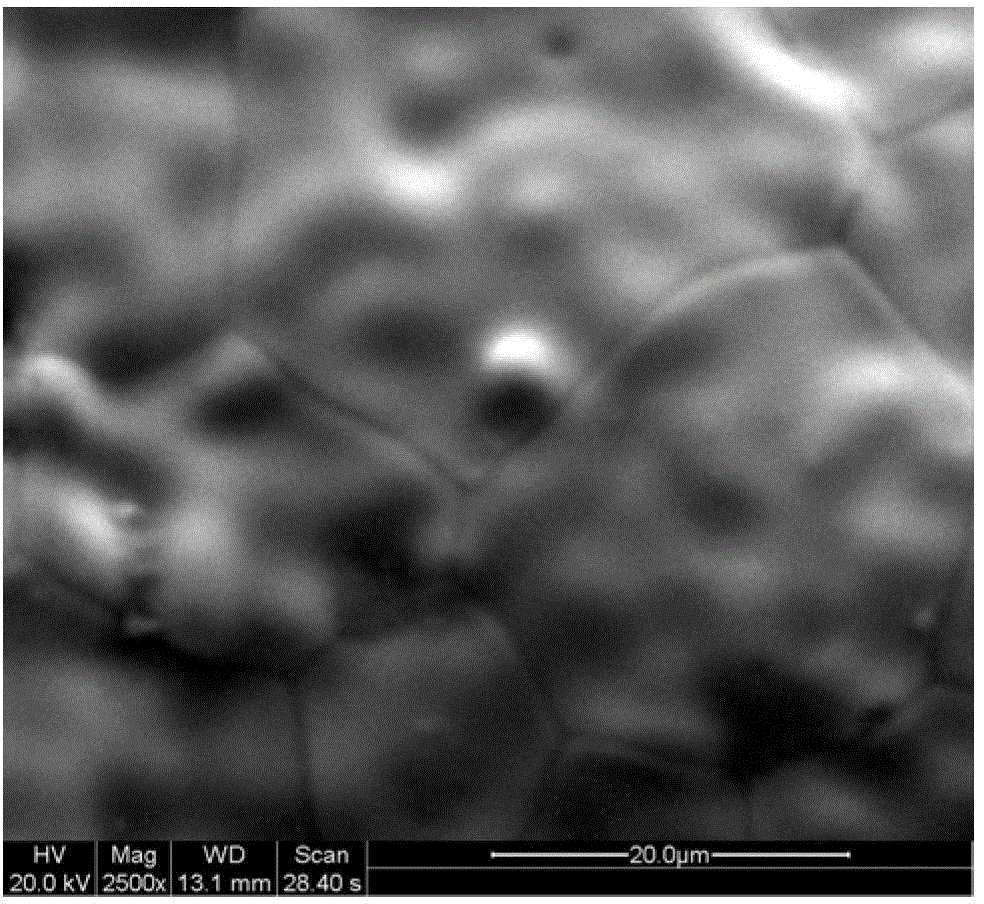

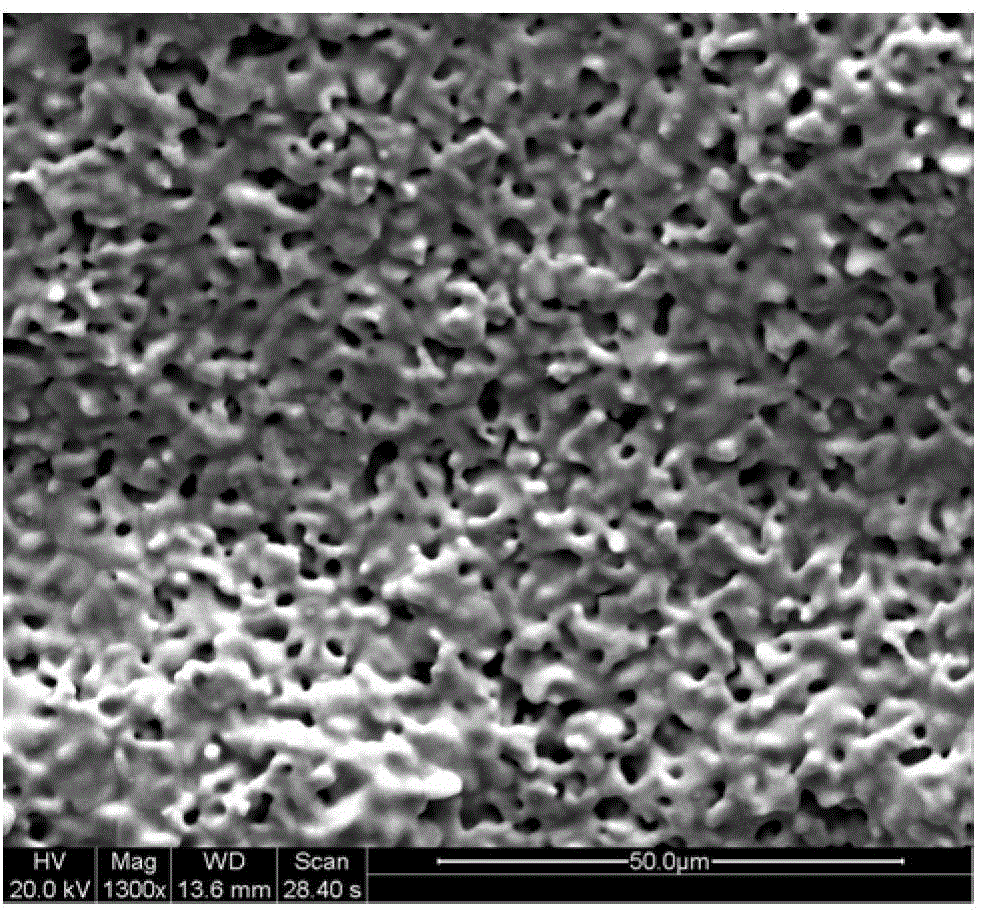

[0031] Both the support and the film layer are perovskite SrCo 0.4 Fe 0.5 Zr 0.1 o 3-δ Ionic-electronic mixed conductor materials. The support body material is synthesized by a high-temperature solid-phase method, and its particle size is 80 μm. A tubular support body green body with an inner diameter of 1 mm and a thickness of 0.75 mm is prepared by plastic extrusion, which contains 15 wt% of activated carbon as a pore-forming agent; membrane The layer material was prepared by the joint complexation method of improved citric acid and EDTA, and its particle size was 10 μm. Then, 3.96g of the film layer material was moved into 31.57g of ethanol, and then 0.17g of Tween-80 and 0.30g of glycerin were added as The dispersing agent is uniformly dispersed under ultrasonic conditions to obtain a suspension; the green body of the support body is placed in a resistance wire heating box with an ambient temperature of 150 ° C, and it is rotated at a speed of 200 r / min, and the spray g...

Embodiment 2

[0033] The support is Brownmillerite type Ca 2 FeAlO 5 Ionic and electronic mixed conductor materials, the film layers are all perovskite La 0.6 Sr 0.4 co 0.8 Fe 0.2 o 3-δ Ionic-electronic mixed conductor materials. The support body material was synthesized by the improved citric acid method, and its particle size was 60 μm. A tubular support body green body with an inner diameter of 30 mm and a thickness of 5 mm was prepared by plastic extrusion method, which contained 30 wt% of pore-forming agent, pore-forming agent It is made by mixing graphite and methyl cellulose according to the mass ratio of 1:1; the film layer material is also prepared by the improved citric acid method, and the particle size is 20 μm, and then 14g of the film layer material is transferred into 18.60g of isopropanol and 7.20g of In the mixed solution of ethylene glycol, add 6.862g fish oil again as dispersant, disperse evenly with mechanical ball mill, obtain suspension; The support body green bo...

Embodiment 3

[0035] The support is perovskite La 0.6 Sr 0.4 Ga 0.3 Fe 0.65 Al 0.05 o 3-δ Ionic and electronic mixed conductor material, the film layer is K 2 NiF 4 Type La 2 NiO 4+δ Ionic-electronic mixed conductor materials. The support body material was synthesized by high-temperature solid-state reaction method, and its particle size was 100 μm. A tubular support body green body with an inner diameter of 18 mm and a thickness of 2.5 mm was prepared by isostatic pressing method, which contained 20 wt% of pore-forming agent. The pore agent is made by mixing starch and polypropylene according to the mass ratio of 1:2; the film layer material is prepared by citric acid method, and the particle size is 5 μm, and then 4.2g of the film layer material is moved into 28.7g of n-octane, and then Add 2.1g glyceryl stearate as a dispersant, and disperse evenly with a mechanical ball mill to obtain a suspension; the green body of the support body is placed in an ambient temperature of 300°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com