Determination method of hexavalent chromium in basic chromium sulfate

A determination method and hexavalent chromium technology, applied in the field of chemical analysis, can solve the problems of being easily absorbed by the human body, harmful to health, difficult to treat waste liquid, and harmful to the environment. Effects of Interfering Elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

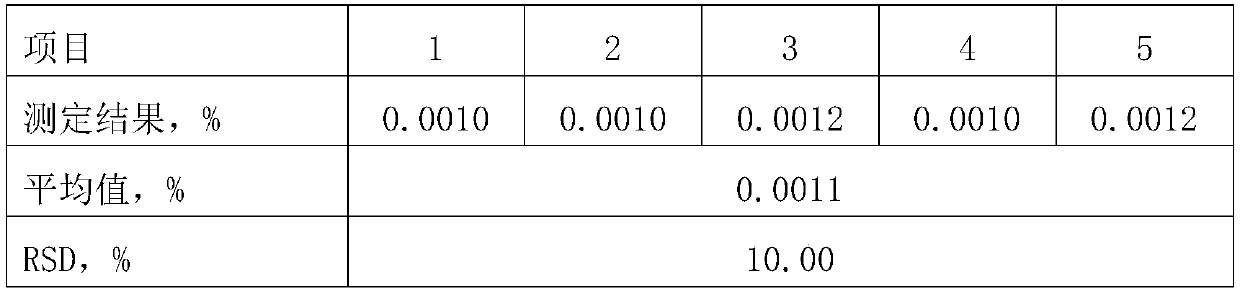

[0050] The mensuration of hexavalent chromium content in the basic chromium sulfate of embodiment 1

[0051] 1. Separation of hexavalent chromium: Weigh 5 samples of basic chromium sulfate to be tested, put 1.0000g of each sample in a 250mL beaker, add hot water at 75°C to dissolve the sample. Immediately after the sample was dissolved, 1.0 g of solid magnesium chloride and 0.3 g of ferric chloride were added to the test solution, stirred evenly, and the pH value of the test solution was adjusted to 10 with 0.1 mol / L sodium hydroxide solution. Incubate on a low-temperature heating plate at 70°C to 80°C for 40 minutes, filter while hot with medium-speed filter paper, wash the precipitate with hot water 8 times, transfer the filtrate into a 100.0mL volumetric flask, dilute to the mark with water, and mix well.

[0052] 2. Color development: Separate 50.0mL of the filtrate into a 100mL volumetric flask, adjust the pH to 6~7 with 0.1mol / L~0.2mol / L sulfuric acid, add 4.0mL of 2.57m...

Embodiment 2

[0058] The determination recovery rate of hexavalent chromium content in embodiment 2 basic chromium sulfate chromium

[0059] Take by weighing 4 parts of basic chromium sulfate samples in Example 1, each part of 1.0000g in a 250mL beaker, add 0.0, 2.0, 4.0, 6.0mL of Cr respectively 6+ Standard solution (prepared according to 3.10.2 in GB / T 223.12-1991, Cr 6+ The concentration of the standard solution is 2.0ug / mL) plus hot water at 75°C to dissolve the sample. Immediately after the sample is dissolved, add 1.0 g of solid magnesium chloride and 0.3 g of ferric chloride to the test solution, stir evenly, and adjust the pH of the test solution to about 1.0 with 0.1 mol / L sodium hydroxide solution. Incubate on a low-temperature heating plate at 80°C for 40 minutes, filter while hot with medium-speed filter paper, wash the precipitate with hot water 8 times, transfer the filtrate into a 100mL volumetric flask, dilute to the mark with water, and mix well. Separate 50.0mL of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com