A micro-aperture mems acoustic array sensor and its application method

An acoustic array and sensor technology, which is applied in the field of acoustic target detection and recognition in the field, can solve the problems of difficult miniaturization of acoustic array design, poor precision of machining technology, high weight, etc., and achieve rich peripheral interfaces and environmental adaptability The effect of strong ability, convenient carrying and deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

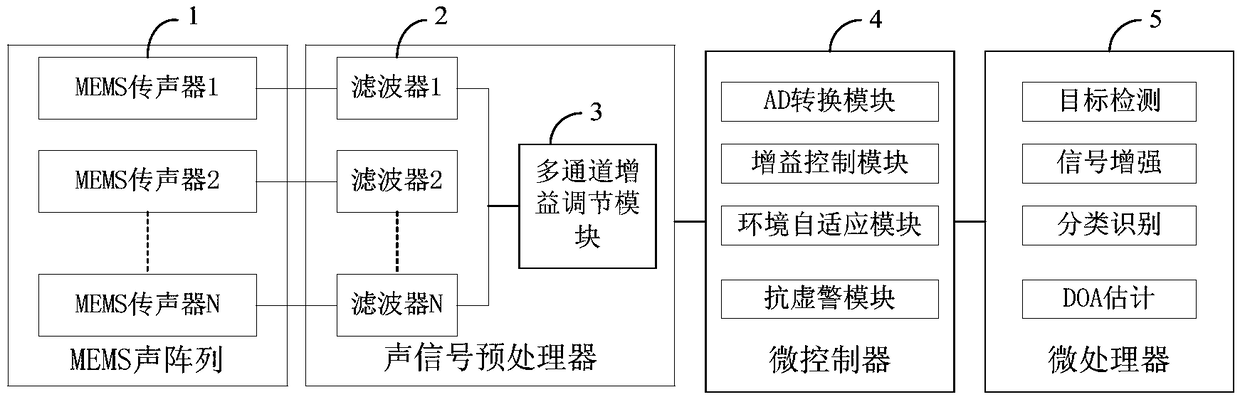

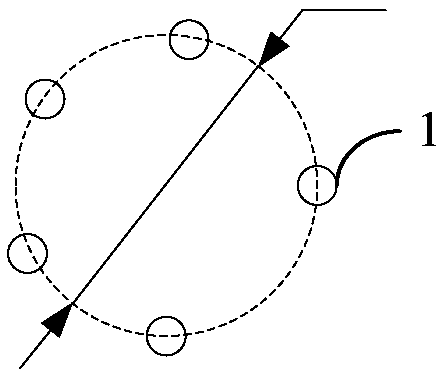

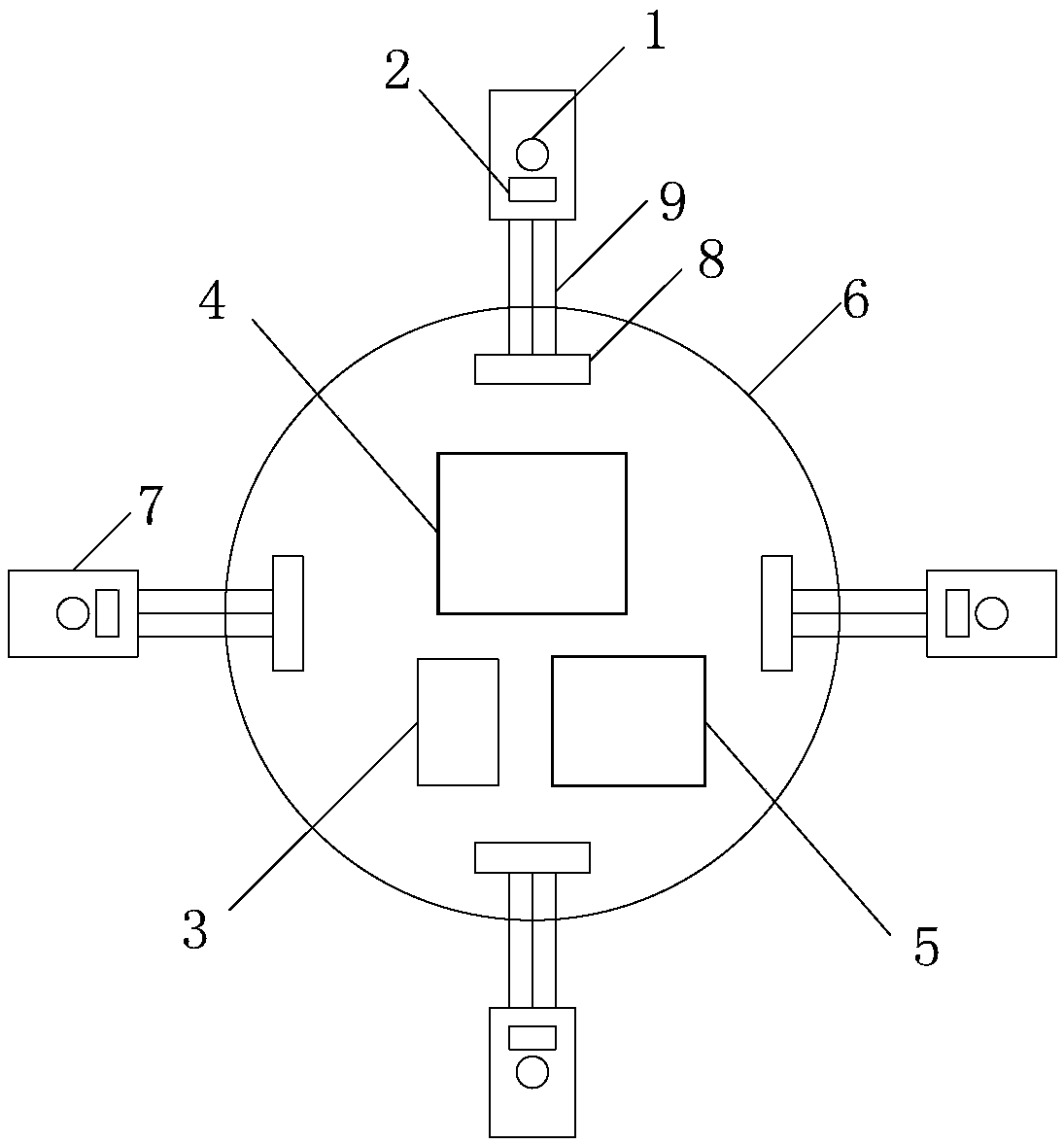

[0034] Such as figure 1 As shown, the micro-aperture MEMS acoustic array sensor of the present invention includes a MEMS acoustic array, an acoustic signal preprocessor, a microcontroller 4 and a microprocessor 5 connected in sequence. Wherein, the MEMS acoustic array includes N (N≥4) MEMS microphones 1 distributed symmetrically and uniformly in the center, and each MEMS microphone 1 is used to collect acoustic signals and convert the acoustic signals into electrical signals for output. exist figure 2 In the shown embodiment, the MEMS microphones 1 are preferably distributed in a circle, and in order to meet miniaturization, the diameter of the circle is preferably less than 100mm. Acoustic signal preprocessor comprises the filter 2 that N road is connected with MEMS microphone 1 one-to-one correspondence, and the multi-channel gain adjustment module 3 that is respectively connected with each filter 2, and filter 2 is used for the electrical output of corresponding MEMS micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com