Self-learning error correction system and method for numerically-controlled machine tool

A technology for correcting errors and CNC machine tools, which is applied in the field of servo system control, can solve problems such as inability to learn independently, and achieve the effects of improving tracking performance, increasing yield, and suppressing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

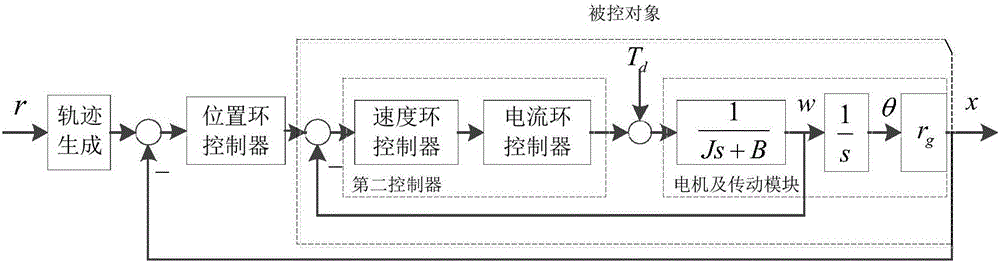

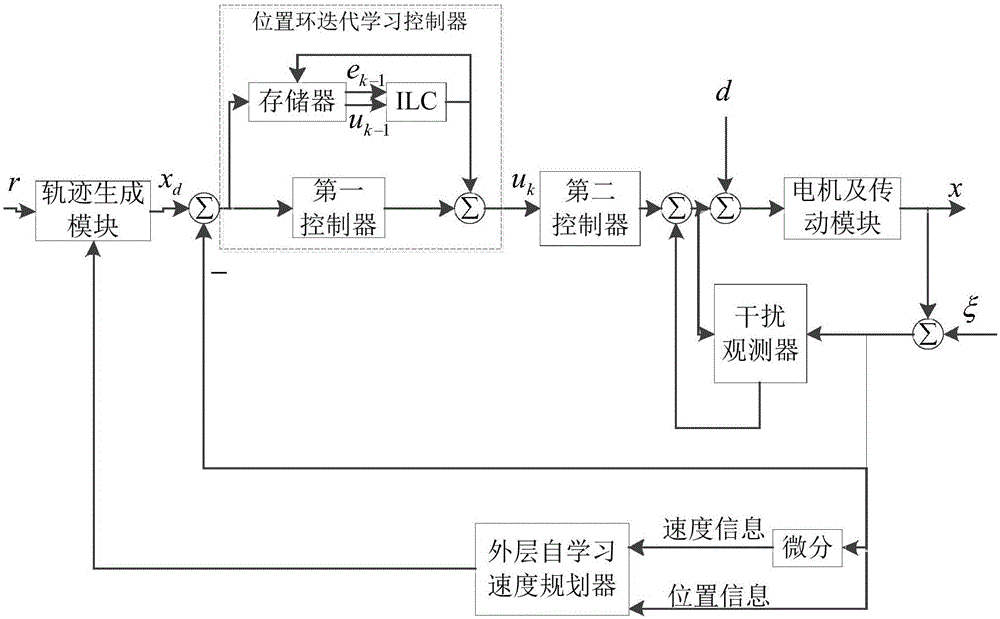

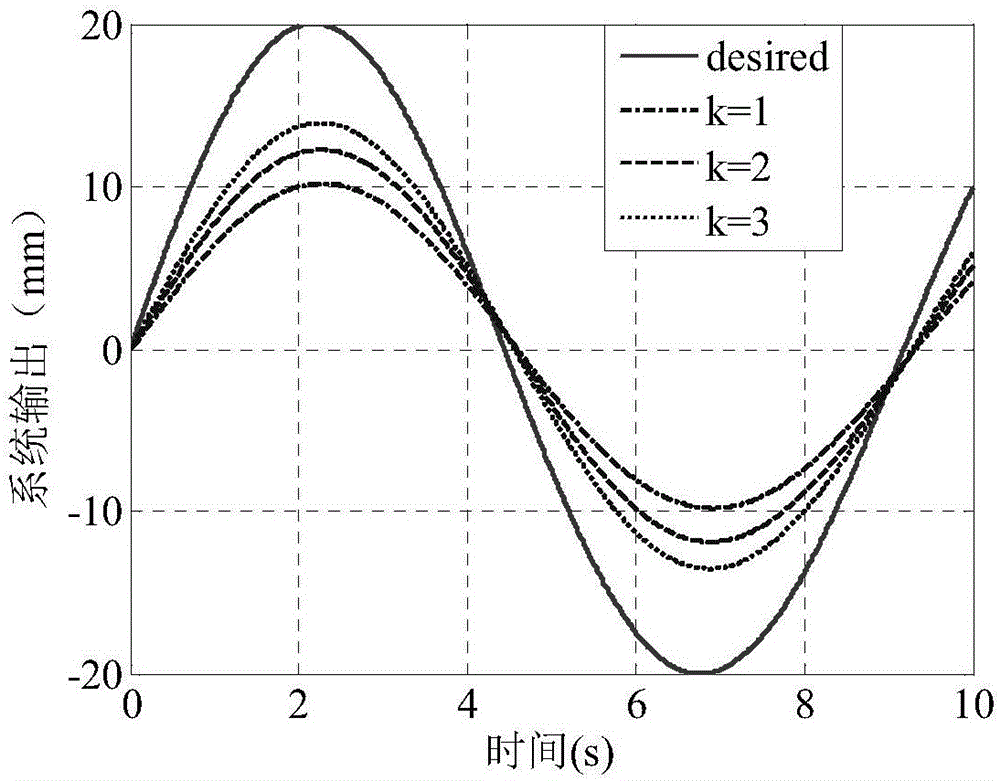

[0049] like figure 2 As shown, in order to realize the self-learning function of accumulating error experience and autonomously correcting errors in the numerical control system in repeated machining, the present invention designs a double-layer self-learning structure, and performs learning and correction at the controller level and trajectory planning level.

[0050] The self-learning correction error system of the CNC machine tool of the present invention includes a trajectory generation module, a position loop iterative learning controller, a second controller, a motor and a transmission module, the output end of the trajectory generation module and the input end of the position loop iterative learning controller The input end of the second controller is connected to the output end of the position loop iterative learning controller, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com