Calculation method for time lag tolerance index of chemical reactor system

A reactor system and calculation method technology, applied in calculation, computer-aided design, instrument and other directions, can solve problems such as deterioration of operating conditions and reduction of heat transfer coefficient, and achieve the effect of improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

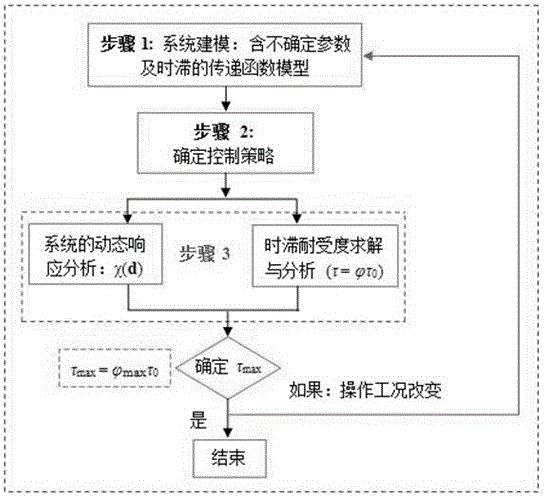

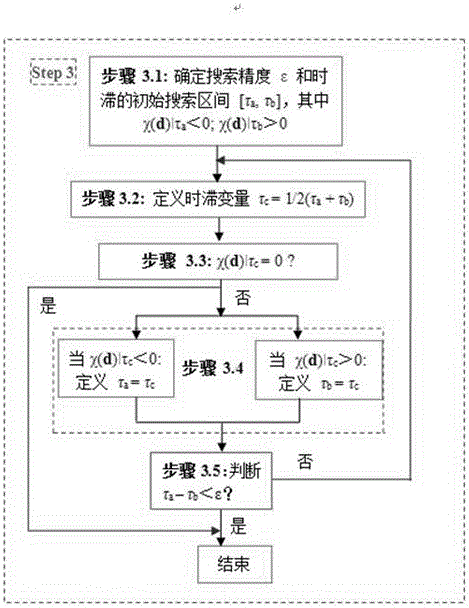

Method used

Image

Examples

Embodiment Construction

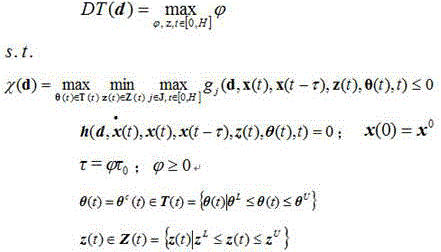

[0020] Assuming that the critical point of uncertain parameter change that limits the flexibility of the system can be determined or known, by introducing the delay tolerance index variable , referring to the flexibility index problem (DFI), the following expression model of the chemical system delay tolerance problem (DTI) is obtained:

[0021]

[0022] in, d is a design vector related to the size of the operating unit, which remains unchanged during the operation; x To describe the state variables of the process system; z is a vector set of control variables that can be adjusted; θ for uncertain parameters and T is the change interval of the uncertain parameter; h and g are process equality constraints and inequality constraints, respectively; superscripts U and L represent uncertain parameters θ and control variable z upper and lower limits; t is the time variable, τ Indicates the lag time variable of the system; in the above formula, if x (d) ≤ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com