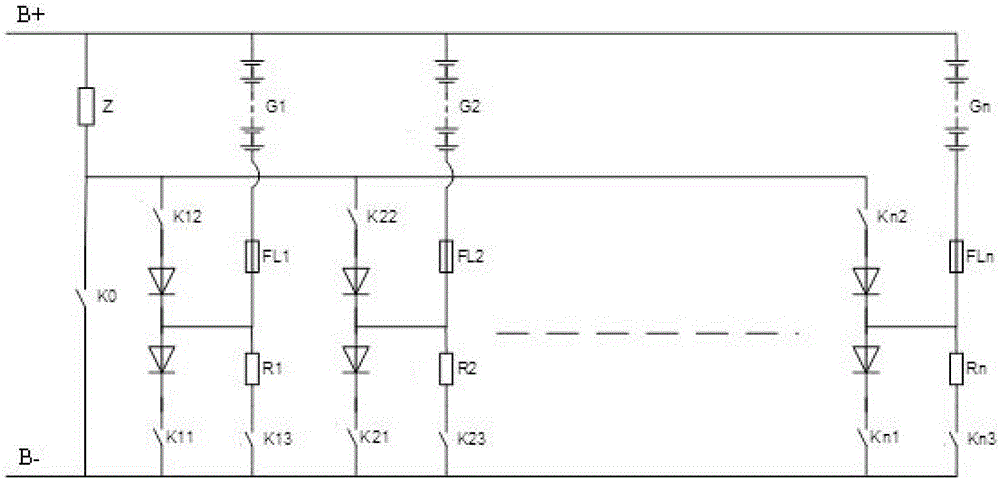

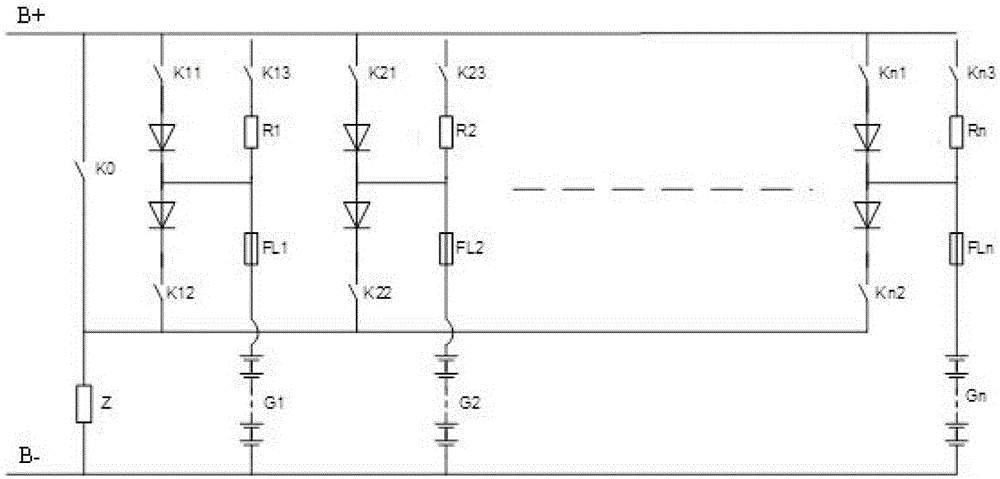

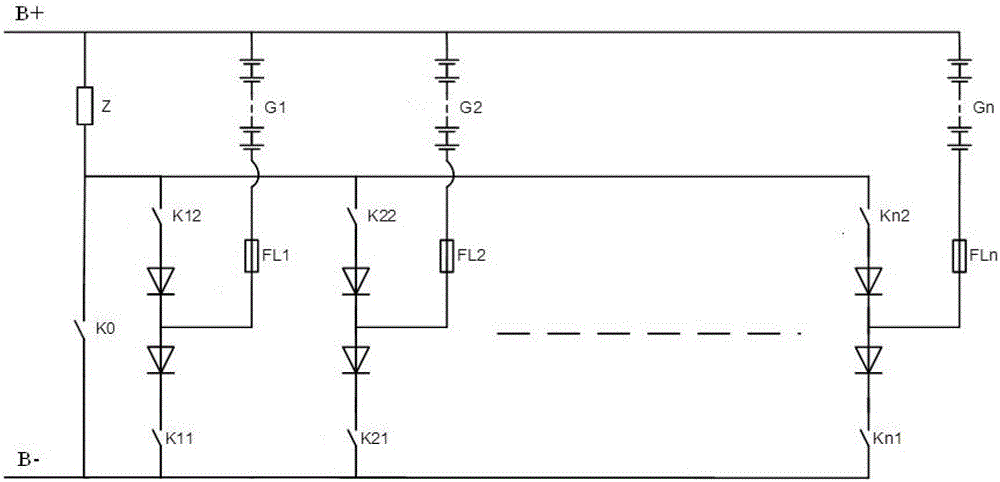

Matrix control method for multiple battery packs in communication base station

A communication base station, matrix control technology, applied in the field of corresponding control units, can solve the problem of no battery charge and discharge management system, achieve good economic and social benefits, reduce carbon emissions and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1 (one group of lead-acid, two groups of ladder batteries, three or four types of mains):

[0052] There are the first, second, and third combination circuit units, one of which uses lead-acid as the battery pack, and the other two uses step-by-step lithium batteries. Image 6 In the case of commercial power, diesel engine) as a switching power supply. Appropriate charging methods: sequential charging, continuous floating charging after the lead-acid battery is fully charged, optional floating charging or standby power shelving after the ladder lithium battery is fully charged, simultaneous discharge after the AC power failure, and cut off the discharge circuit when the battery is discharged to the secondary power-off voltage . When the mains is normal, the load is always powered by the charger (switching power supply).

Embodiment 2

[0053] Example 2 (three sets of ladder batteries, new energy working conditions):

[0054] The first, second, and third combined circuit units all use step-by-step lithium batteries. When applied to new energy conditions (ie Image 6 When the fan and / or photovoltaic panel are used as the source of the switching power supply B+, B-). Suitable charging method: charging at the same time, because of the current limiting protection, overcharging will not occur. After being fully charged, it can be float charged according to requirements, and can be set aside for backup. When discharging, the ladder lithium battery is loaded and discharged.

Embodiment 3

[0055] Example 3 (one set of lead-acid, two sets of cascade batteries, peak-shaving and valley-filling working conditions):

[0056] There are the first, second, and third combination circuit units, one of which uses lead-acid as the battery pack, and the other two uses step-by-step lithium batteries, which are used to solve the phenomenon of peak-shaving and valley-filling of switching power supplies. Appropriate operation mode: charge at the same time when charging is required, disconnect the charger from the load when discharging is required, discharge with load by the step-by-step lithium battery, and reserve with lead-acid;

[0057] Valley power supply for 8 hours: start charging; flat power supply for 8 hours, keep fully charged; peak power supply battery discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com