MMC apparatus sub-module capacitor voltage balance method by adopting model predictive control

A technology of model predictive control and sub-module voltage, which is applied to output power conversion devices, electrical components, and conversion of AC power input to DC power output. Improve transient performance, avoid geometric multiple growth, and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

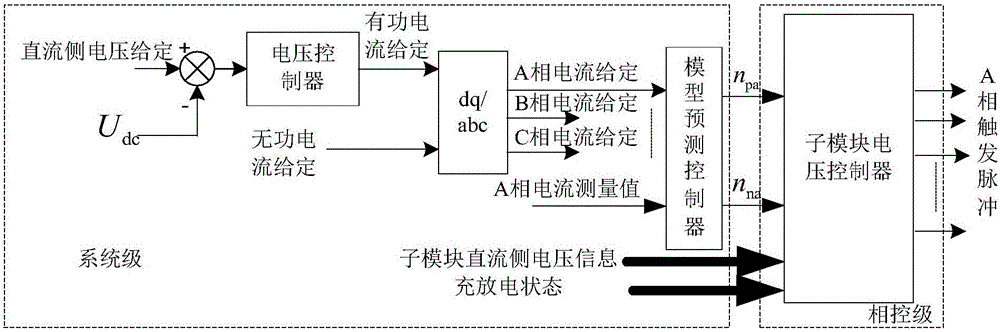

[0054] In the present invention, the MMC control circuit includes a system level and a phase control level. The system level includes an AD sampling conditioning circuit and a main control CPU. The information sent by the Hall sensor is connected to the system level control circuit, and the system level control circuit sends the generated control signal to the phase control level control circuit.

[0055] The phase control level control circuit combines the sub-module DC side capacitor voltage information, charge and discharge status and the control information output by the model predictive controller input from the system level to generate, and the sub-module capacitor voltage is graded and pulse-distributed through the sub-module voltage controller. The finally generated trigger pulse signal is connected to the controlled end of the corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com