Method for preparing buttered tea through food processor

A food processing machine and food processing technology, applied to utensils with integral electric heating devices, cooking utensils, household utensils, etc., can solve the problems of excessive dependence on labor and uncontrollable temperature, and achieve simple and reliable operation, liberate manpower, and save users good experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

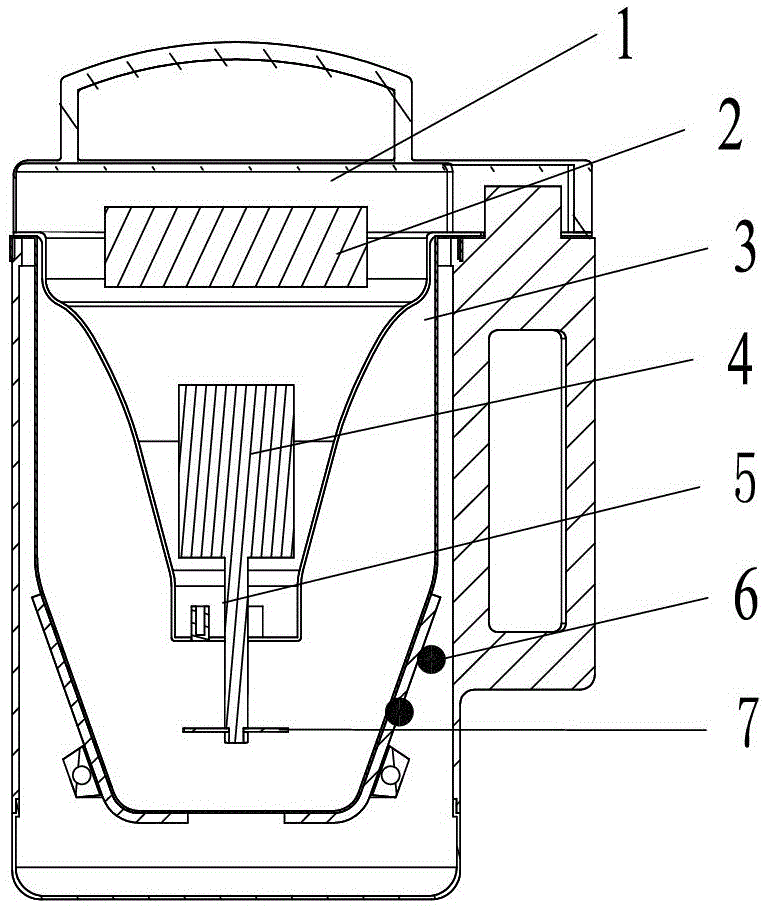

[0031] The food processing machine involved in the present invention includes a soybean milk machine, a cooking machine with heating, and the like. Wherein, the motor on the food processing machine can be set up or down. For example, if the motor is placed down, the motor is located in the lower frame, and a coupling is connected to the upper part of the motor shaft. The upper end extends into the cup body and connects with the cutter shaft set at the lower end of the cup body. The blade or stirring device is installed on the upper end of the cutter shaft, and the motor drives the blade or stirring device together with the coupling; The disassembled structure is that the motor shaft does not pass through the coupling, but directly drives the blade or the stirring device to work.

[0032] In this embodiment, the way that the motor of the food processing machine is placed on the top is taken as an example. The food processing machine is as figure 1 As shown, the processing mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com