Automatic sand coating equipment and automatic sand coating system

A sand planting and automatic technology, applied to the surface coating liquid device, coating and other directions, can solve the problem of poor sand planting effect and achieve the effect of automatic sand planting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

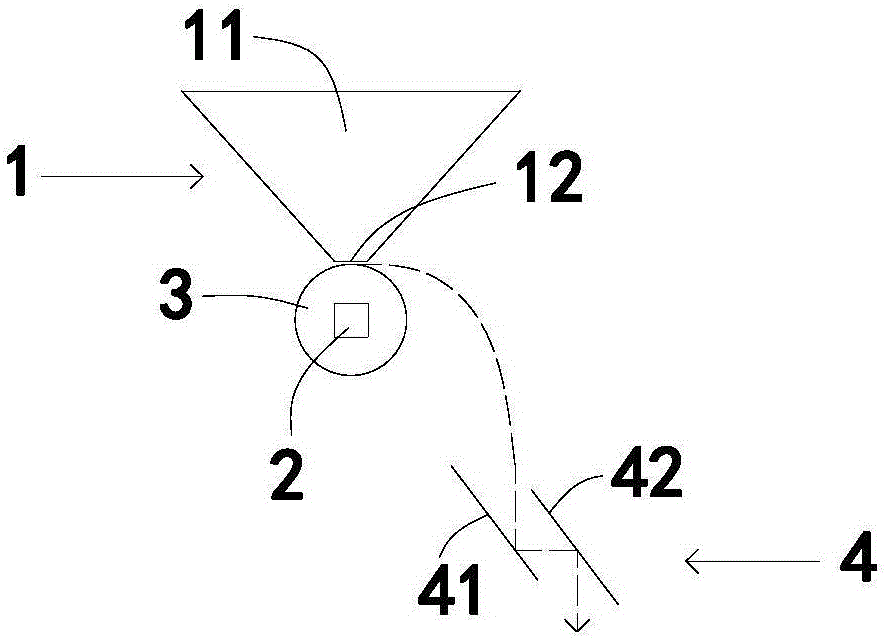

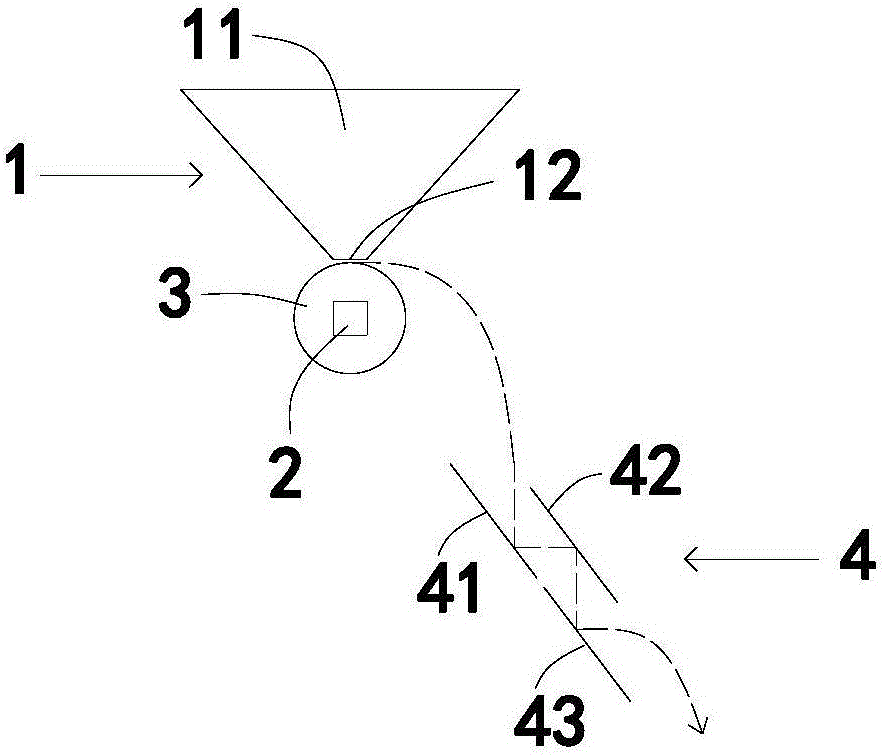

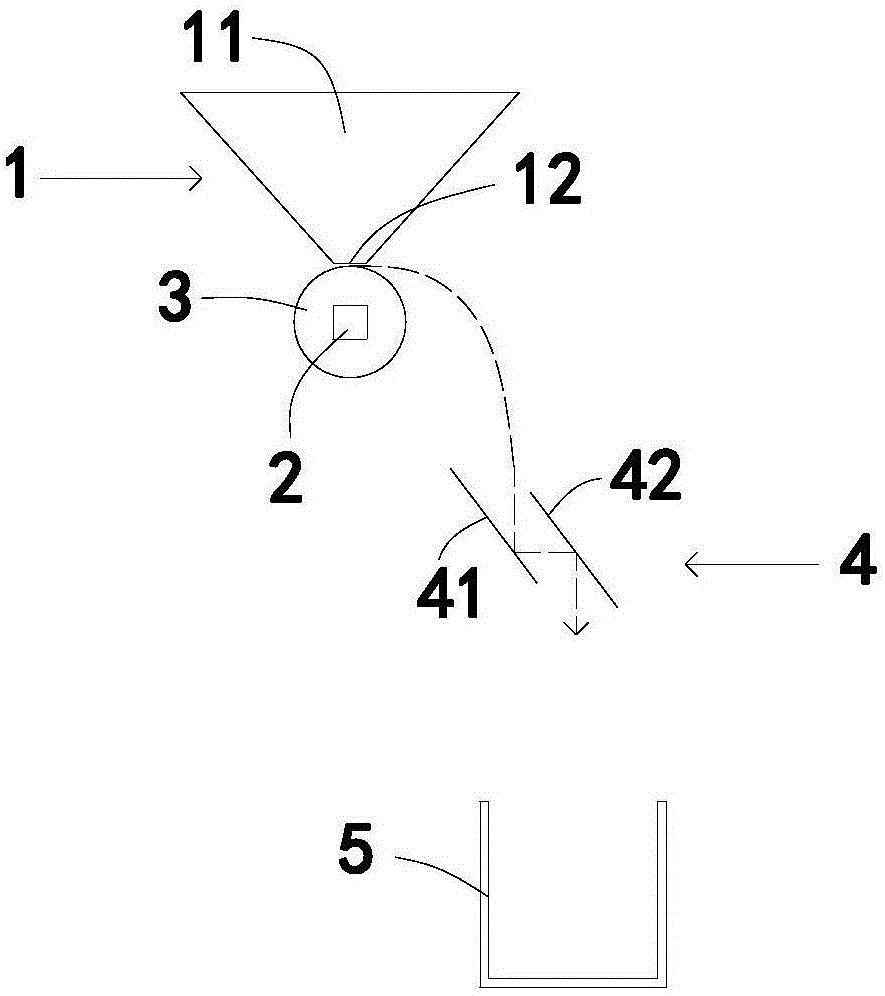

[0045] In a preferred embodiment of the present invention, the inclination of the baffle is 20° to 70°.

[0046] The splashing angle of the sand material is mainly controlled by the inclination of the baffle plate, so in order to ensure that the sand material splashes evenly, how to select the inclination of the baffle plate is particularly important; in order to solve this problem, this embodiment sets the inclination of the baffle plate as 20° to 70°, within this range, the sand material can be splashed evenly, wherein, the inclination of the baffle refers to the angle between the lower part of the baffle and the horizontal line.

[0047] A preferred embodiment of the present invention is as follows, the material of the baffle is glass, ceramic plate, acrylic plate or alloy plate.

[0048] In the actual use process, each baffle needs to rebound the sand to the designated position and splash it out. In order to achieve this purpose, this embodiment uses glass, ceramic plates,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com