Machining and producing device for cast iron pipes

A technology for production devices and cast iron pipes, applied in measurement devices, instruments, lining/interior coating, etc., can solve the problems of measurement result influence, production efficiency, pipeline roughness, etc., to improve ease of use and automation, realize Visual operation, easy to measure the effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

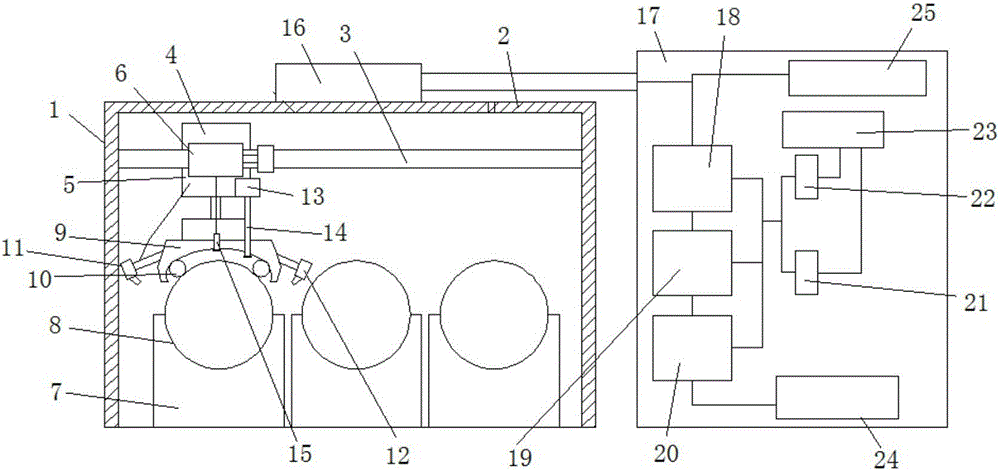

[0009] Referring to the accompanying drawings, a cast iron pipe processing and production device includes a box body 1, a sound insulation layer 2 is provided on the inner wall of the box body 1, and a guide rail 3 is fixedly installed on the inner top of the box body 1, and the guide rail 3 slides A sliding seat 4 is installed, and an adjustable cylinder 5 is installed on the sliding seat 4. A servo motor 6 is installed on the sliding seat 4 to control the left and right movement of the sliding seat 4 to select and detect different pipe fittings. The bottom of the box body 1 is provided with three different support bases 7, the support base 7 is provided with an arc-shaped pipe groove 8, and the lower end of the piston rod of the cylinder 5 is fixedly connected with a pipe frame 9, and the pipe frame 9 is lowered. The surface is provided with a roller 10, the tube frame 9 on the roller 10 is fixedly equipped with an ultrasonic transmitting probe 11 and an ultrasonic receiving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com