Preparation method and application of a ziegler-natta catalyst for efficiently preparing low-entanglement polyethylene

A catalyst and low-entanglement technology, which is used in the preparation of Ziegler-Natta catalysts and the preparation of low-entanglement polyethylene, and achieves the effects of inhibiting the formation of overlapping polyethylene chains, improving polymerization activity, and eliminating bimetal deactivation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

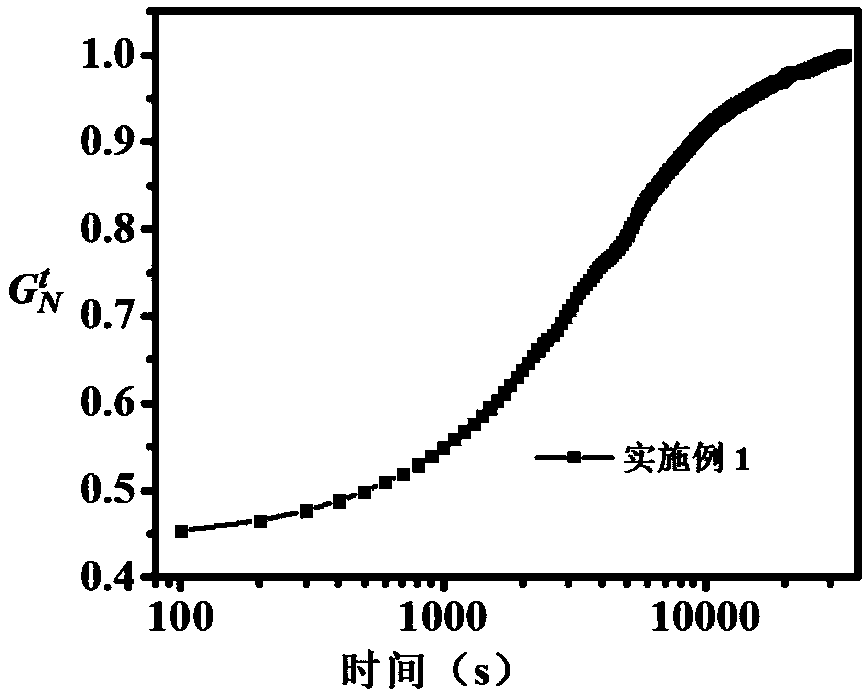

Embodiment 1

[0033] (1). 1.0g porous carrier SiO with a pore diameter of 20nm 2 After mixing with 6mmol of 1,4-butanediol in 20mL of tetrahydrofuran (THF) solution for 4h, the alcohol-modified porous support was obtained, and the alcohol-modified porous support was washed with 20mL of THF for 5 times to obtain 1,4-butanediol A porous carrier for alcohol adsorption; (2). The organic substituents of polyhedral oligomeric silsesquioxane (POSS) molecules are replaced with methyl and hydroxyl groups, wherein one POSS molecule contains two hydroxyl groups to obtain a modified The polyhedral oligomeric silsesquioxane molecule of the POSS molecular diameter is 1nm; (3). The modified polyhedral oligomeric silsesquioxane molecule in step (2) is mixed with 6mmolMgCl 2 (The molar ratio of 1,4-butanediol to magnesium atoms is 1) according to the molar ratio of hydroxyl moles in POSS to Mg atoms is 4%, mixed in 20mLTHF to prepare polyhedral oligomeric silsesquioxane molecules / Mg Mixture; (4). The polyh...

Embodiment 2

[0036] (1). After mixing 1.0g of porous carrier alumina with a pore diameter of 100nm and 6mmol of 1-butanol in 20mL of tetrahydrofuran (THF) solution for 4h, an alcohol-modified porous carrier was obtained, which was washed with 20mL of THF to obtain an alcohol-modified Porous carrier 1 time to obtain a porous carrier adsorbed by 1-butanol; (2). The organic substituents of polyhedral oligomerization silsesquioxane (POSS) molecules are replaced with tert-butyl and hydroxyl groups, wherein one POSS molecule Containing 3 hydroxyl groups on the surface, obtain modified polyhedral oligomerization silsesquioxane molecule, POSS molecular diameter is 10nm; (3). The polyhedral oligomerization silsesquioxane modified in step (2) Molecule and 0.6mmol ethoxymagnesium (1-butanol to magnesium molar ratio is 10) are mixed in 20mLTHF according to the molar ratio of hydroxyl moles and Mg atoms in POSS to prepare polyhedral oligomeric silsesquioxane / Mg mixture; (4). The mixture of polyhedral ...

Embodiment 3

[0039] (1). After mixing 1.0 g of porous carrier titanium dioxide with a pore diameter of 1 μm and 6 mmol of ethanol in 20 mL of tetrahydrofuran (THF) solution for 6 hours, an alcohol-modified porous carrier was obtained, and washed with 20 mL of THF to obtain an alcohol-modified porous carrier for 5 times , to obtain a porous carrier adsorbed by ethanol; (2). The organic substituents of polyhedral oligomerization silsesquioxane (POSS) molecules are substituted with isopropyl and hydroxyl groups, wherein one POSS molecule contains one hydroxyl group , to obtain modified polyhedral oligomerized silsesquioxane molecules, POSS molecular diameter is 20nm; (3). The modified polyhedral oligomerized silsesquioxane molecules in step (2) are mixed with 3mmol magnesium hydroxide ( Ethanol and magnesium molar ratio are 2) according to the mol ratio of hydroxyl molar number and Mg atom in POSS, be 10%, mix in 20mLTHF, prepare polyhedral oligomeric silsesquioxane / Mg mixture; (4). Step (3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com