Heat accumulating type rapid pyrolyzing furnace temperature control method for controlling on-off time of radiant tubes

A temperature control method and time control technology, which is applied in the direction of temperature control by electric method, indirect heating carbonization, coke oven, etc., can solve the problems of single-minded temperature control scheme, complex implementation, and inflexibility, etc., and achieve uniform temperature field, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

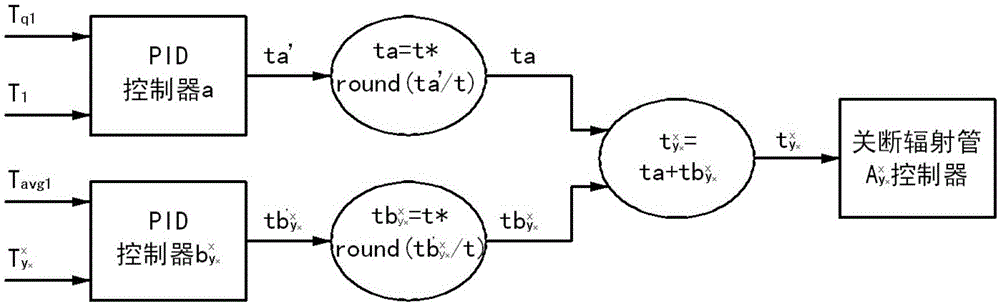

[0038] According to the method, it will be specifically described in conjunction with a laboratory fast pyrolysis furnace. The laboratory fast pyrolysis furnace is controlled by PLC and WinCC of Siemens CPU414-2DP. Therefore, considering the actual situation, the complexity of PLC or WinCC programming and real-time operation of this method, and minimizing the influence of this method on the independent, normal and stable operation of the original control system, the LabView software is used here to implement the OPC service and PLC. data exchange to implement the method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com