Amphoteric retanning fatting agent and preparation method thereof

A retanning and fatliquoring and amphoteric technology, which is applied in the field of amphoteric retanning and fatliquoring agents and their preparation, can solve problems such as reduction, and achieve the effects of mild production process, high exhaustion rate, and shortened retanning and fatliquoring process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment relates to an amphoteric retanning and fatliquoring agent and a preparation method thereof, and its preparation specifically includes the following steps:

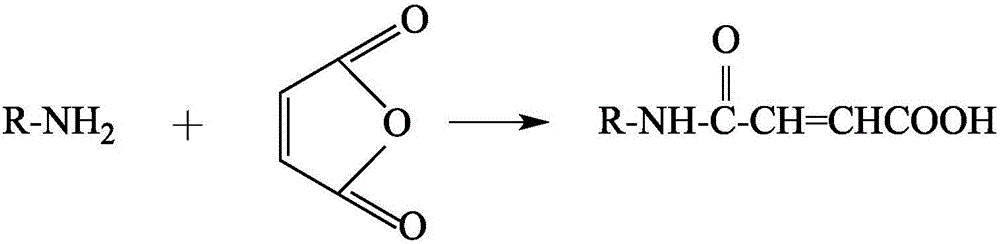

[0036] 1) Synthesis of maleic anhydride monoamide with maleic anhydride and C12-18 carbon amine:

[0037]

[0038] Wherein, R is a C12-C18 alkyl group.

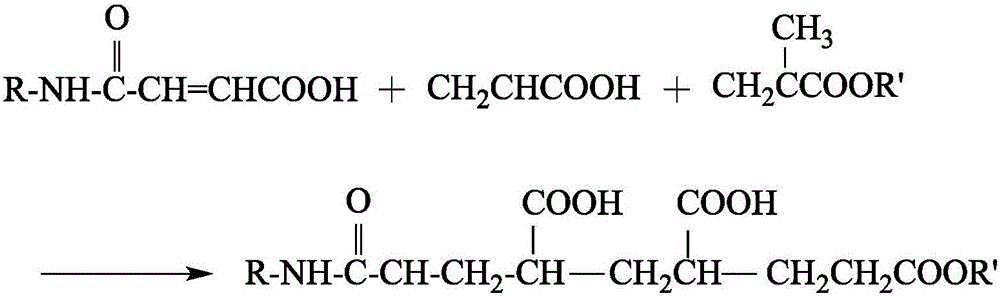

[0039] 2) Maleic anhydride monoamide, acrylic acid, and trimethylaminoethyl methacrylate are copolymerized to form a terpolymer.

[0040]

[0041] Among them, R is an alkyl group of C12~C18, and R' is

[0042] 3) Compounding the synthesized ternary polymer and vegetable oil-modified phosphate according to a certain ratio (1:9-9:1) to obtain retanning type fatliquor with different properties.

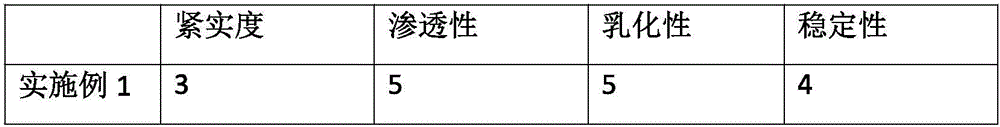

[0043] The preferred ratio is compounded under the condition of 4:6, and the obtained retanning and fatliquoring agent has good retanning and filling effects. In particular, the retanning and fatliquoring process can be simplified without adding othe...

Embodiment 2

[0050] This embodiment relates to a kind of amphoteric retanning and fatliquor and its preparation method, and its preparation method is the same as embodiment 1, the difference is:

[0051] In step 1), maleic anhydride is 40g, and C12 amine is 40g;

[0052] In step 2), maleic anhydride monoamide is 100g, trimethylaminoethyl methacrylate chloride monomer is 120g, and acrylic acid is 50g;

[0053] In step 3), the natural vegetable oil soybean lecithin is 320g, ethylene glycol is 896g, alcoholysis under the condition of pH: 3.5; 2 SO 3 Wash the aqueous solution twice, adjust the pH to 6.5 with ammonia water, then centrifuge to remove the lower layer of oil, then adjust the final pH to 6.5 with 20wt% NaOH solution, and then separate the upper layer by centrifuging waste liquid, and use 5-8wt % solubility sodium chloride solution after washing, add 0.1wt% antifungal agent and 0.1wt% rose essence to obtain vegetable oil modified phosphate ester;

[0054] In step 4), the mass rat...

Embodiment 3

[0056] This embodiment relates to a kind of amphoteric retanning and fatliquor and its preparation method, and its preparation method is the same as embodiment 1, the difference is:

[0057] In step 1), maleic anhydride is 40g, and C18 amine is 50g;

[0058] In step 2), maleic anhydride monoamide is 100g, trimethylaminoethyl methacrylate chloride monomer is 200g, and acrylic acid is 80g;

[0059] In step 3), the natural vegetable oil soybean lecithin is 320g, ethylene glycol is 902g, alcoholysis under the condition of pH: 4.5; 2 SO 3 Wash the aqueous solution twice, adjust the pH to 7.0 with ammonia water, then centrifuge to remove the lower layer of oil, then adjust the final pH to 7.5 with 30wt% NaOH solution, and then separate the upper layer from the centrifuged waste liquid, and use 5 to 8 wt% of the lower layer to % solubility sodium chloride solution after washing, add 3.0wt% antifungal agent and 1.0wt% rose essence to obtain vegetable oil modified phosphate;

[0060...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com