Gear quenching device

A quenching device and gear technology, applied in the direction of quenching device, furnace, heat treatment equipment, etc., can solve the problems of increasing gear ellipse and warping deformation, uneven heating on the upper and lower sides of the tooth end, large gear diameter and weight, etc. Achieve the effect of avoiding ellipse and warpage, simple structure and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will now be further described in conjunction with specific examples. The following examples are intended to illustrate the present invention but not to further limit the present invention.

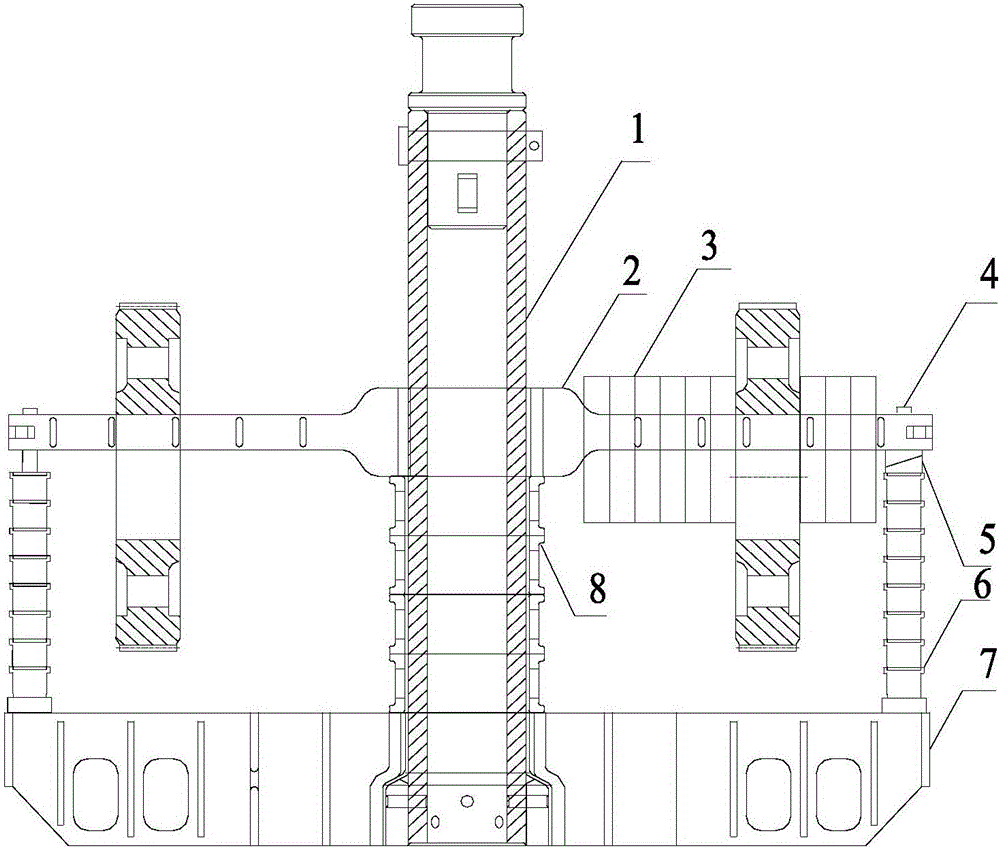

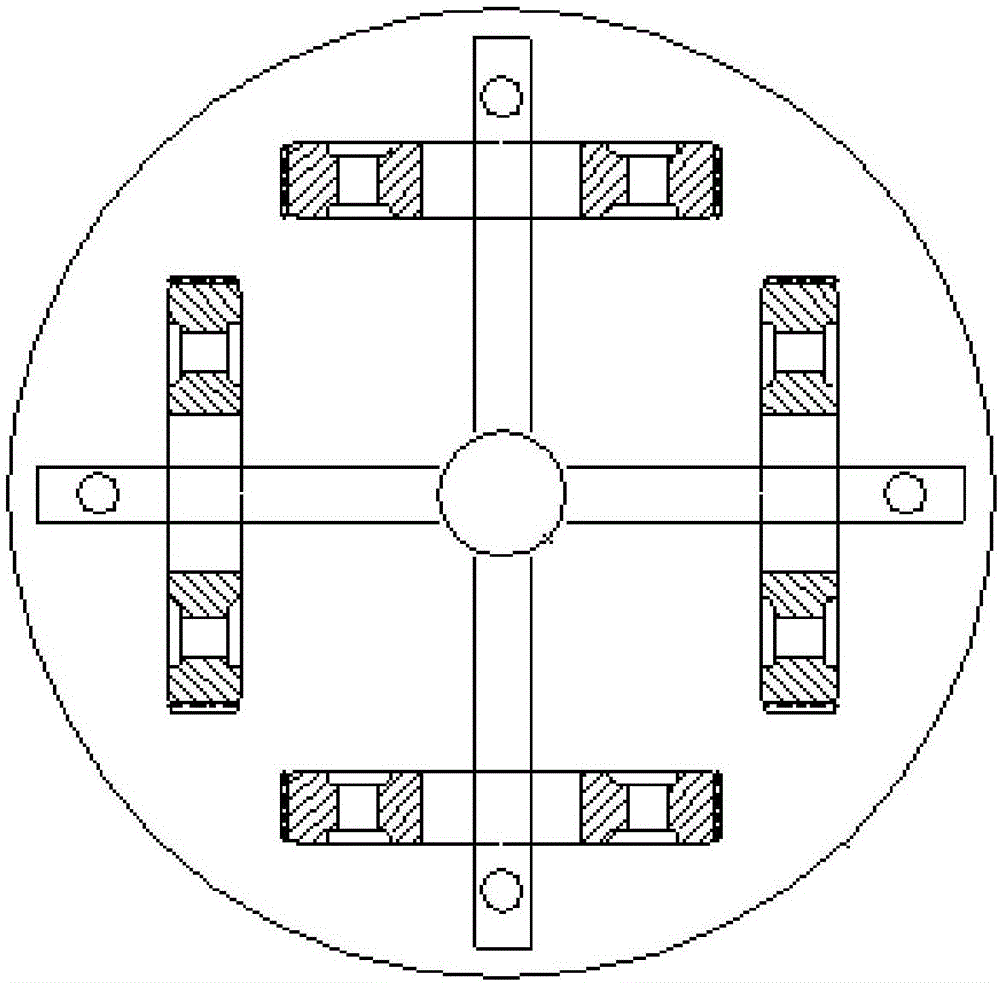

[0018] Such as figure 1 , 2 The gear quenching device shown includes a chassis 7, a boom 1 vertically installed in the center of the chassis 7, a cross-shaped cantilever fin beam 2 with a center hole in the center, the boom 1 passes through the center hole, and the cantilever fin beam A number of spacers 8 are stacked on the outer side of the boom 1 between 2 and the chassis 7, and the gears are symmetrically inserted on the cantilever wing beam 2. The four outer ends of the cantilever wing beam 2 are provided with peripheral holes. A vertical bracket 4 whose lower end is connected to the upper surface of the chassis 7 is penetrated in the hole. The vertical bracket 4 between the cantilever wing beam 2 and the chassis 7 is sleeved with a plurality of sleeves 6 stac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com