Method for detecting emergent laser rays of laser level based on machine vision

A laser level meter and machine vision technology, applied in the direction of instruments, measuring devices, etc., can solve the problems of failure to realize automation, stop, and inability to intelligently judge the width and position of the outgoing laser line, and achieve the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

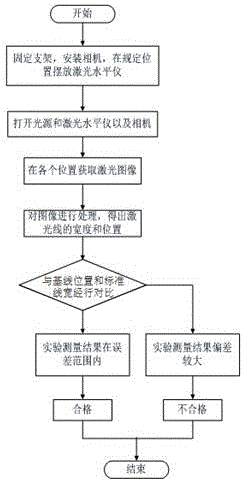

[0031] Such as figure 1 As shown, a machine vision-based laser level meter exit laser line detection method includes the following steps:

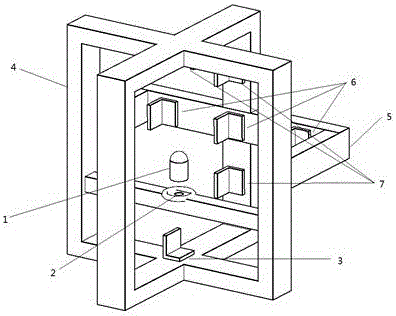

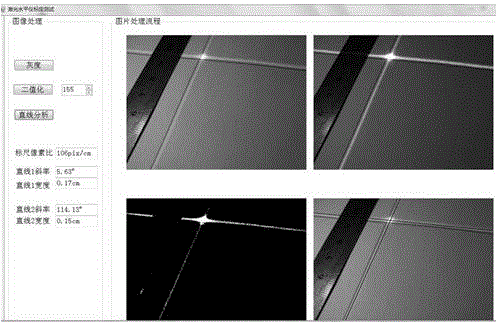

[0032] 1) Real-time collection of multiple image data of multiple horizontal or vertical laser lines; that is, using multiple cameras installed on the detection frame to collect real-time image data of laser lines within the field of view of each camera. Such as figure 2 As shown, 1 is the laser level, 2 is the placement position of the laser level, and there is an opening below it to locate whether the laser level is placed correctly. 3, 6 and 7 are a set of calibration boards, mounting brackets and cameras to collect the laser lines of each part respectively. Among them, 3 cameras collect images of the positioning points at the bottom of the laser level, and 6 three groups of cameras are separated by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com