Method for detecting photocurrent signal of photoelectric conversion material with conductive atomic force microscope

An atomic force microscope and photoelectric conversion material technology, applied in the field of signal detection, can solve the problems of difficulty in distinguishing current amplifiers, rising material temperature, affecting the accuracy of test results, etc., and achieve the effect of suppressing useless noise and improving the detection signal-to-noise ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

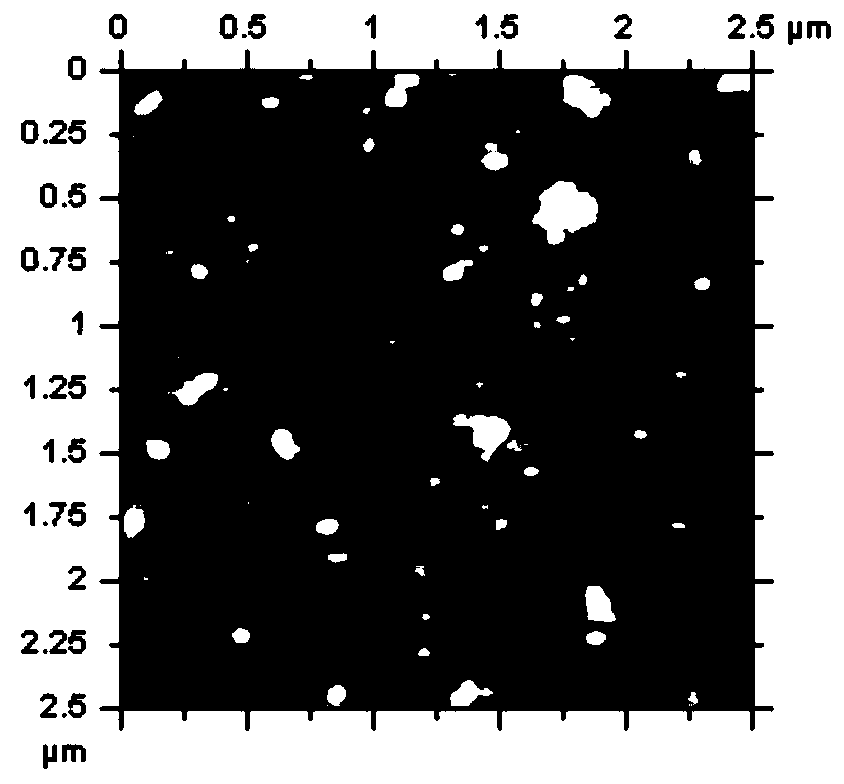

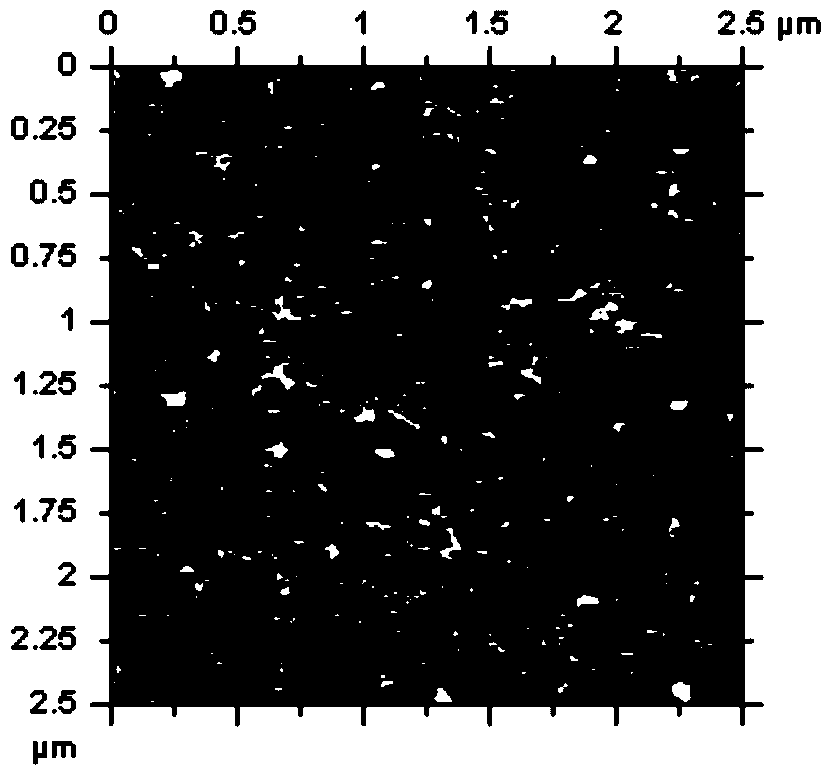

[0028] In this embodiment, the sample is an ITO / P3HT:PCBM film sample with a photoelectric conversion effect, and the surface morphology and photocurrent distribution of the sample are tested by a conductive atomic force microscope.

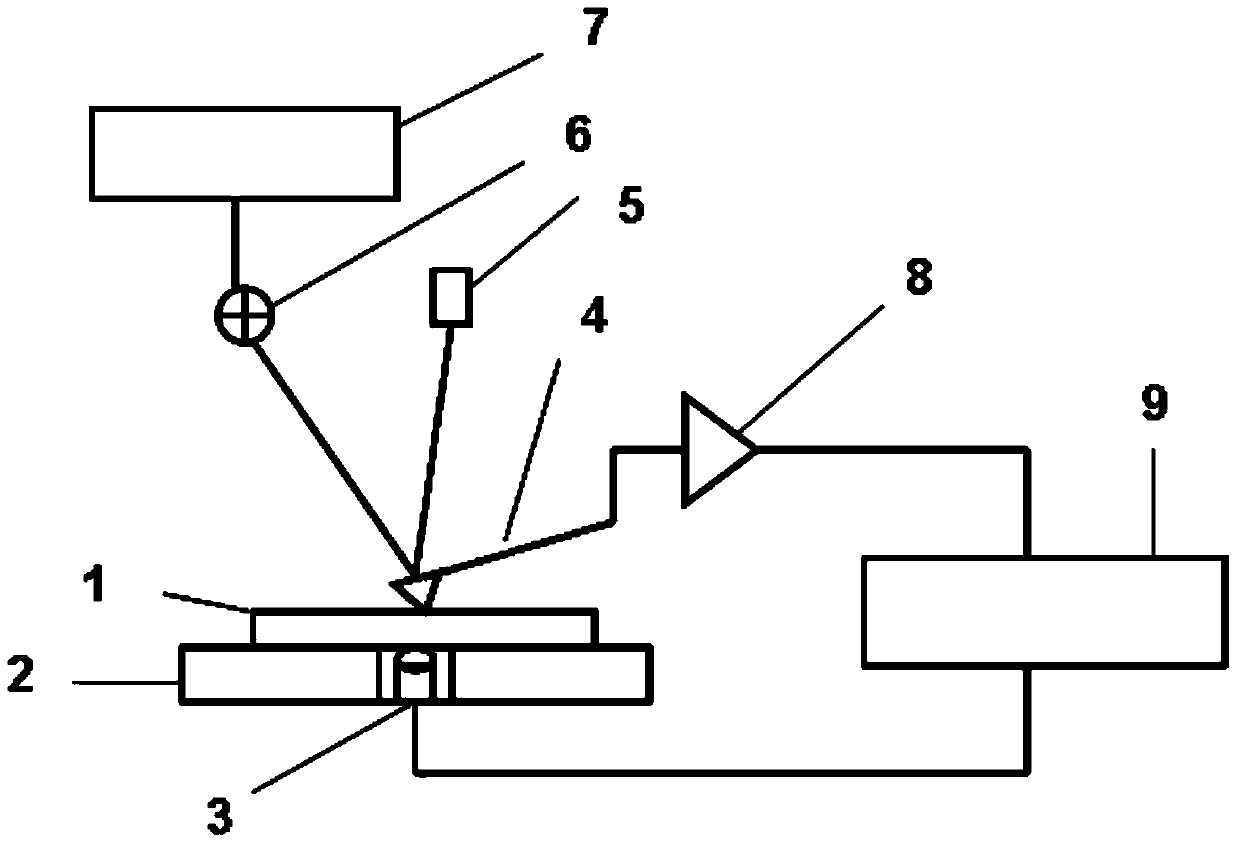

[0029] The structure diagram of the test platform is as follows: figure 1 As shown, it includes a microscopic topography detection part and a photocurrent signal detection part.

[0030] The microscopic morphology detection process is as follows: the sample 1 is placed on the sample stage 2 of the atomic force microscope micromirror, and the tip of the conductive probe 4 forms a stable contact with the sample. The light source of the laser 5 is incident on the surface of the probe 4 and reflected to the four-quadrant photodetector 6 . The four-quadrant photodetector 6 converts the optical signal into an electrical signal and inputs it to the controller 7 of the atomic force microscope.

[0031] The photocurrent signal detection process is as fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com