Infrared methane measuring device and measuring method capable of realizing accurate positioning

A technology of precise positioning and measuring device, which is applied in the direction of measuring device, color/spectral characteristic measurement, material analysis by optical means, etc. The effect of improving detection accuracy and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation of the present invention will be described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0035] like Figure 1-10 As shown, the object of the present invention is to overcome the shortcomings of the prior art, and provide an infrared methane measurement device and measurement method that can be accurately positioned.

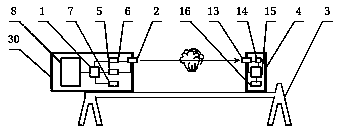

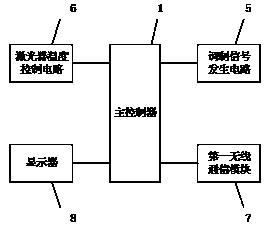

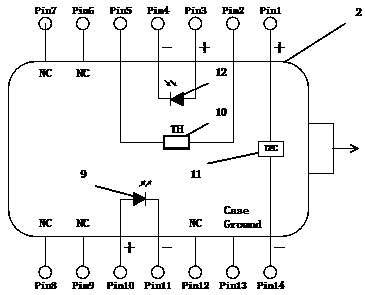

[0036] The purpose of the present invention is achieved through the following technical solutions: a precisely positioned infrared methane measuring device, which includes a main controller 1, a distributed feedback laser 2, a telescopic structure 3, a baffle plate 4, an explosion-proof casing 30 and a system power supply, The main controller 1 is respectively connected with the modulation signal generating circuit 5, the laser temperature control circuit 6, the first wireless communication module 7 and the display 8 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com