Infrared phase locking and imaging method and device for surface and subsurface defect detection of optimal element

A technology for subsurface defects and optical components, applied in the direction of optical testing flaws/defects, etc., can solve the problems of low sensitivity, low resolution, surface and subsurface absorption defects of transparent optical components, etc., to suppress useless noise and improve detection. Signal-to-noise ratio, the effect of improving detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

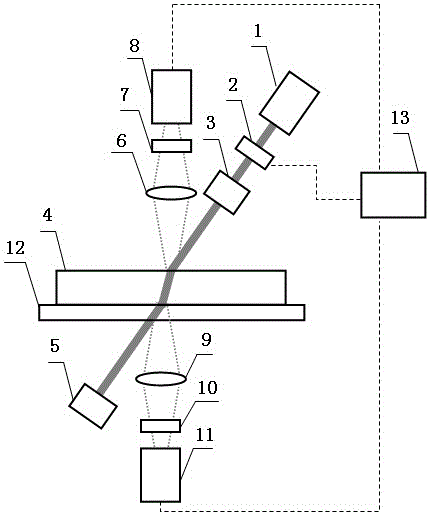

[0023] See figure 1 , an infrared phase-locked imaging device for detecting surface and subsurface defects of an optical element, including a pumping light source 1 arranged relative to the front surface of the optical element 4, and a pump sequentially arranged between the emitting end of the pumping light source 1 and the front surface of the optical element 4 The pump beam modulation device 2 and the pump beam shaping processing device 3, the pump light absorbing device 5 arranged on the rear surface of the optical element 4, and the first infrared imaging device 6 arranged on the front surface of the optical element 4 are sequentially arranged on the first infrared The first infrared filtering device 7 and the first infrared detector array 8 at the rear end of the imaging device 7, the second infrared imaging device 9 arranged on the rear surface of the optical element 1, and the second infrared filtering device arranged at the rear end of the second infrared imaging device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com