Climbing-free winding and tying device for transmission line tree barrier cutting

A transmission line and tree barrier technology, which is applied in the field of transmission line tree barrier felling, free-climbing tree winding and tethering device, can solve the problems of cleaning personnel such as high labor intensity, falling from high altitude, and easy electric shock, so as to improve the efficiency of live maintenance, The effect of ensuring safe and reliable operation and reducing the probability of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

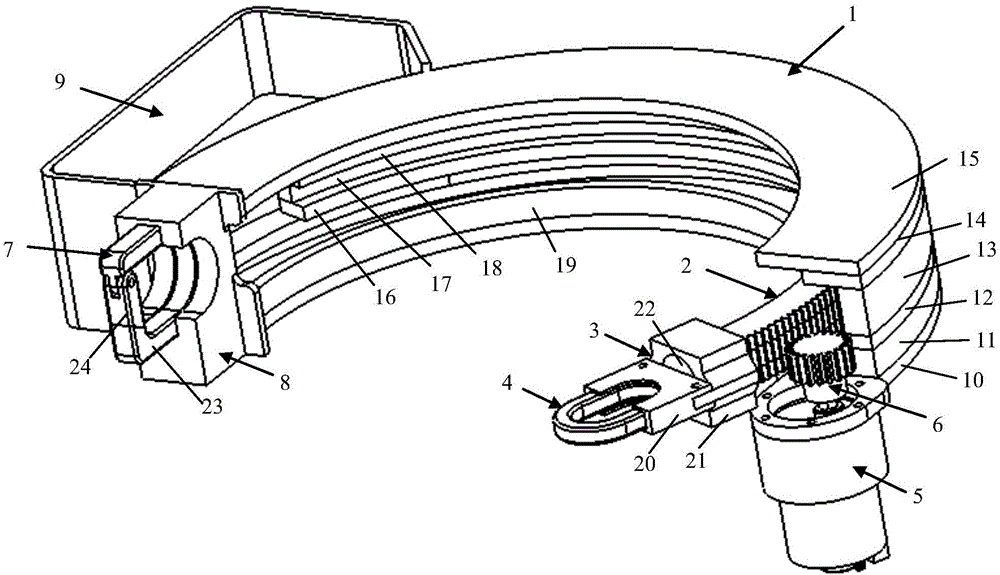

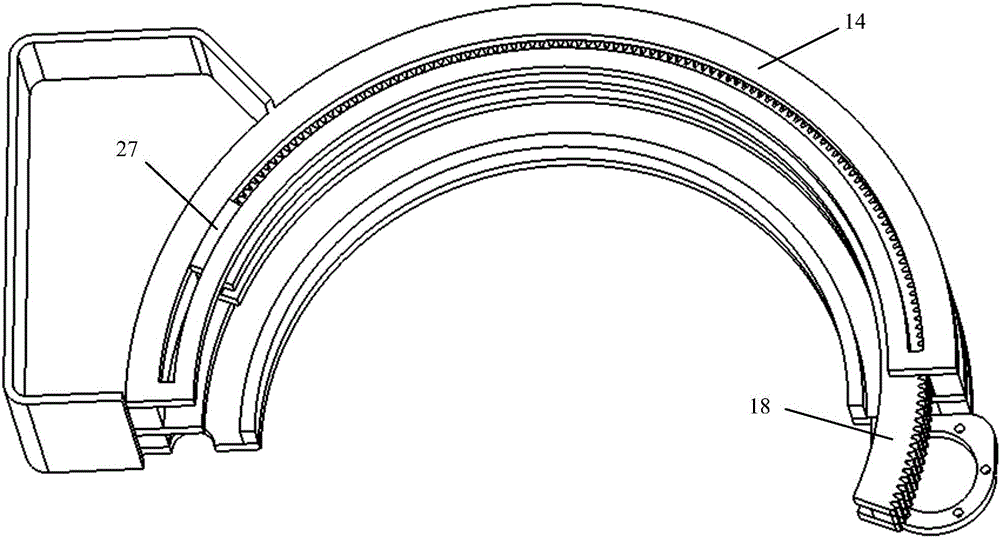

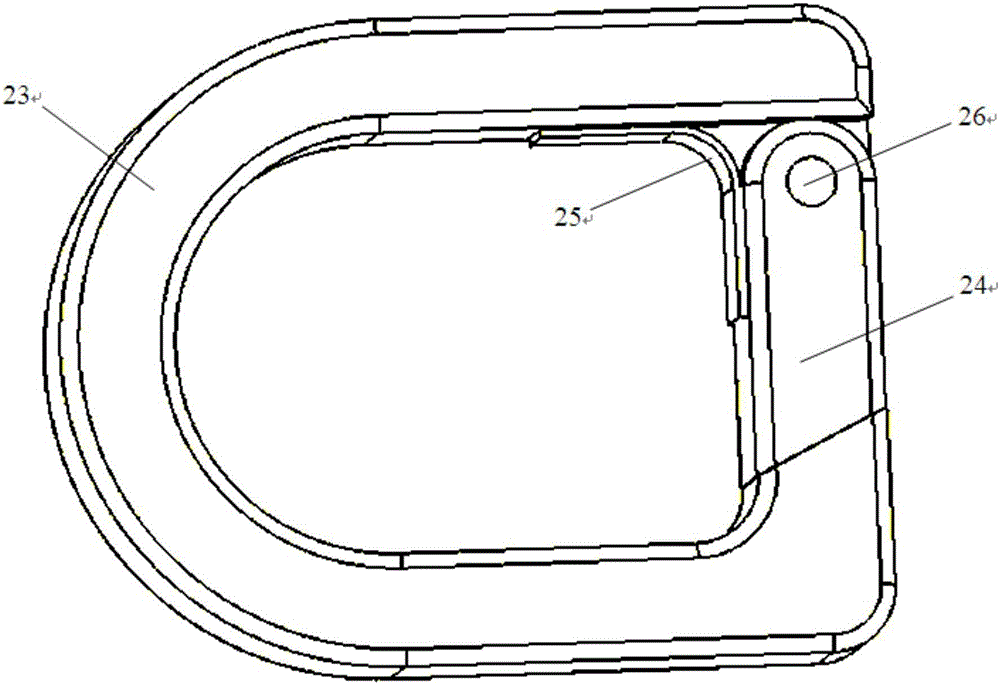

[0020] A power transmission line tree barrier felling free climbing tree winding tether device, comprising a hoop shell 1, a hoop core 2, a ring fixing mechanism 3, a ring 4, a reduction motor 5, a pinion 6, a ring buckle 7, and a ring Buckle the fixed block 8 and the battery circuit box 9, the hoop shell 1 is formed by laminations 11, 12, 13, 14, 15 and 19 connected by bolts; 18 is superimposed through bolt connection, with a rope groove in the middle, and the hoop shell and hoop core form a rope feeding mechanism that moves along a fixed track; the ring fixing mechanism is composed of a ring groove 20, a ring groove fixing block 21 And electromagnet 22 forms; Described ring buckle is made up of button body 23, block 24, leaf spring 25 and ring buckle pin 26; Form buckle ring mechanism by ring buckle and ring.

[0021] The top layer 18 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com