Vertical grain drying device used for agriculture

A drying device and agricultural technology, applied in drying, drying machines, heating devices, etc., can solve the problems of no preheating device, poor working environment, uneven drying, etc., and achieve reduced labor intensity and simple structure , Improve the effect of drying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

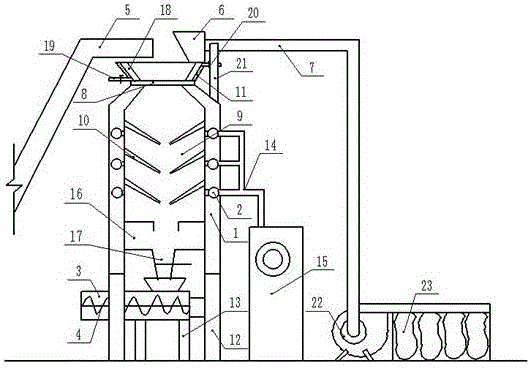

[0012] see figure 1 , a vertical agricultural grain drying device, comprising a heating tower 1, a hot air pipe 14, a grain feeding port 8, a hot air blower 15, an exhaust fan 22, a cavity 18 and a feeding hinge 5, the heating tower 1 The bottom of the heating tower 1 is evenly distributed with a plurality of brackets 12, and the heating tower 1 is erected on the ground through the brackets 12. The top of the heating tower 1 is provided with a grain feeding port 8, and the heating tower 1 below the grain feeding port 8 is provided with a heating section 9 inside. Section 9 is provided with multi-layer grain guiding plates 10 arranged obliquely downwards, and an annular hot air pipe 2 is arranged between every adjacent two groups of grain guiding plates 10, and the annular hot air pipe 2 communicates with the hot air pipe 14, and The annular hot bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com