Non-weaving lattice apron for compact spinning

A non-woven and mesh ring technology, which is applied in spinning machines, textiles, papermaking, drafting equipment, etc., can solve the problems of easy weathering of nylon filaments, and achieve the effects of easy size, not easy to wear and deform, and increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

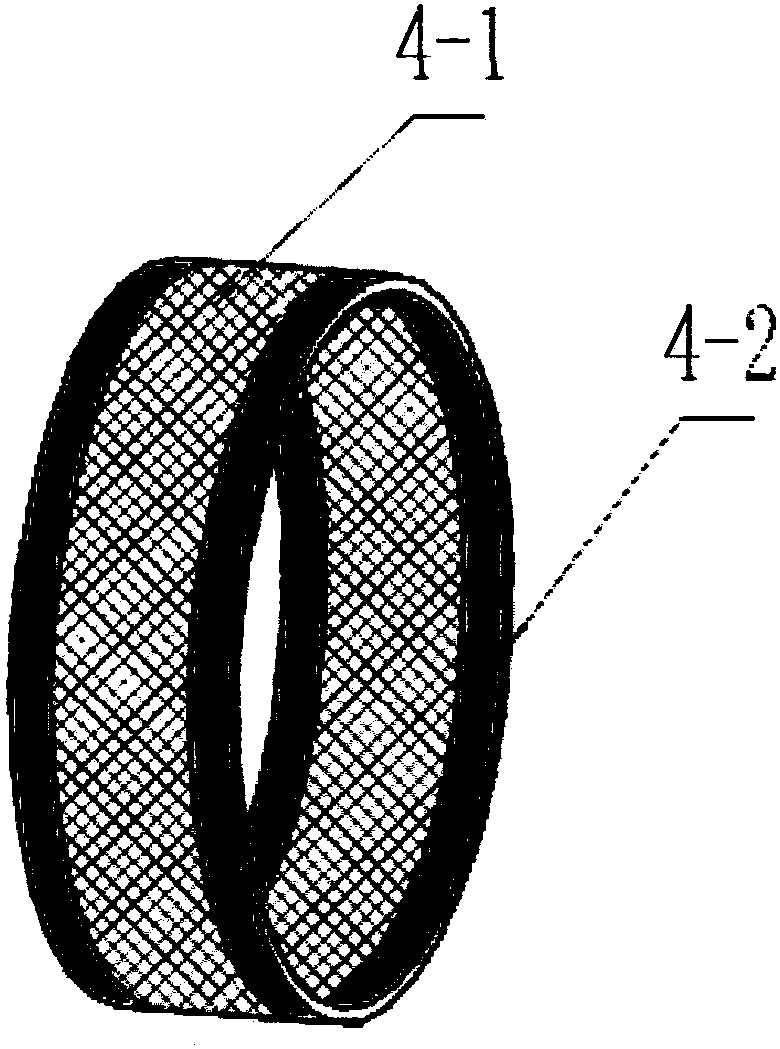

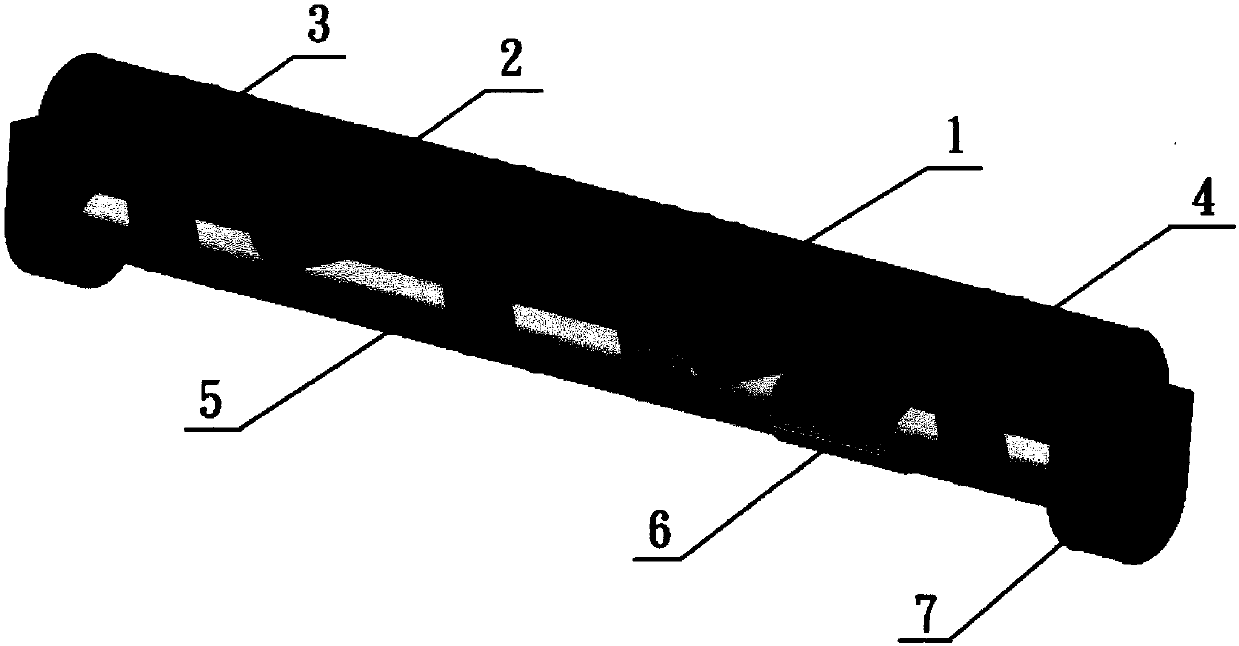

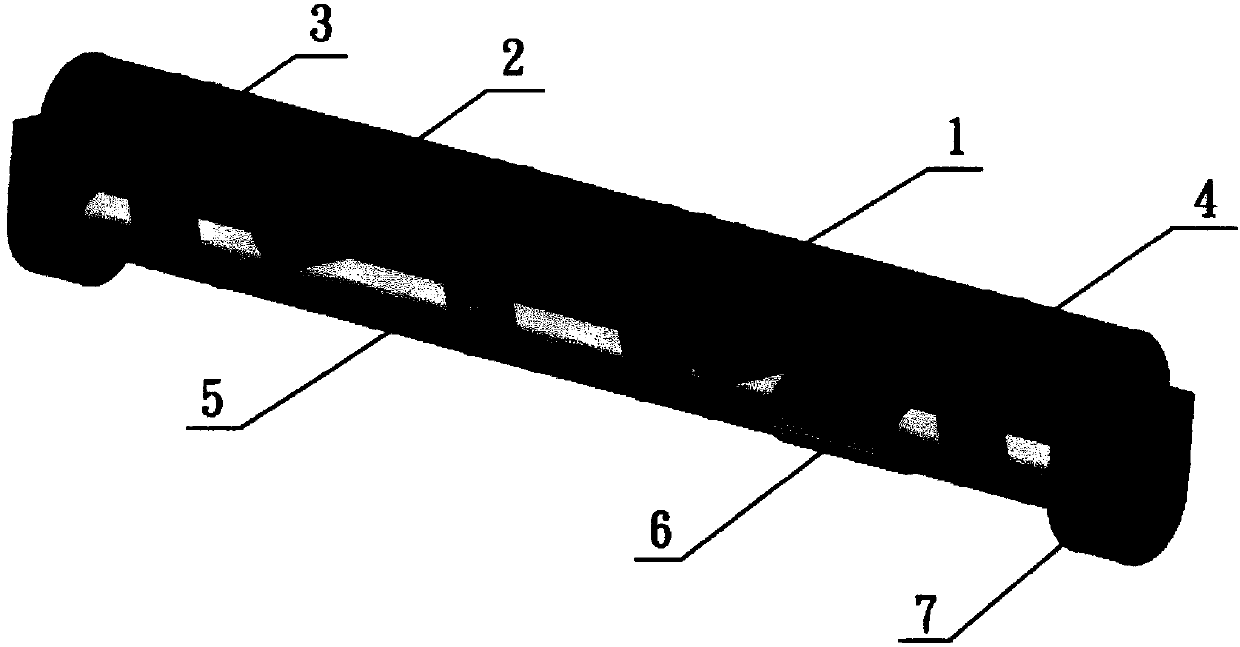

[0013] Such as figure 1 , figure 2 As shown, a grid ring for non-woven compact spinning, including a vacuum tube body 1, an air suction port 2, an air slot 3, a grid ring 4 for non-woven compact spinning, a transmission roller 5, a gear belt 6, and a fixing seat 7. The vacuum pipe body 1 is provided with two suction ports 2 and four air slots 3, the lower end of the vacuum pipe body 1 is provided with a transmission roller 5, and the right side of the transmission roller 5 is provided with a gear belt 6, and each air slot 3 corresponds to a A grid ring 4 for non-woven compact spinning, the transmission roller 5 rotates, and the grid ring 4 for non-woven compact spinning also rotates under the action of tension and friction, the vacuum tube body 1 and the The transmission roller 5 is fixedly connected together b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com