Tool and method for controlling coplanarity, position tolerance and perpendicularity of CCGA device welding columns

A positional and coplanar technology, applied in the direction of manufacturing tools, grinding devices, working carriers, etc., can solve problems such as large positional degree and verticality of welding posts, poor consistency of welding post heights, and poor quality of surface mount components , to achieve the effect of avoiding mechanical damage, low cost and good verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

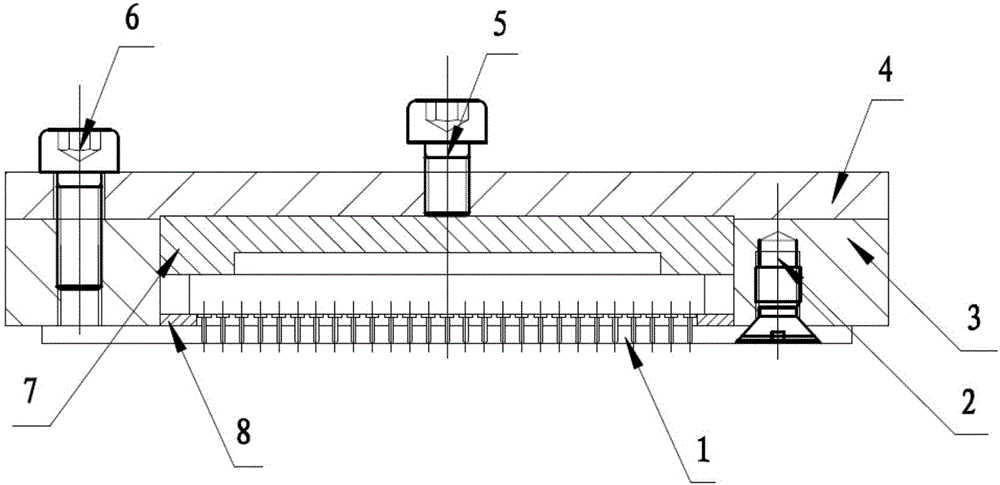

[0050] Using a method of controlling the coplanarity, position and verticality of the device soldering pillars proposed by the present invention, a CCGA717 circuit is processed after the pillars are planted, and the following effects are achieved:

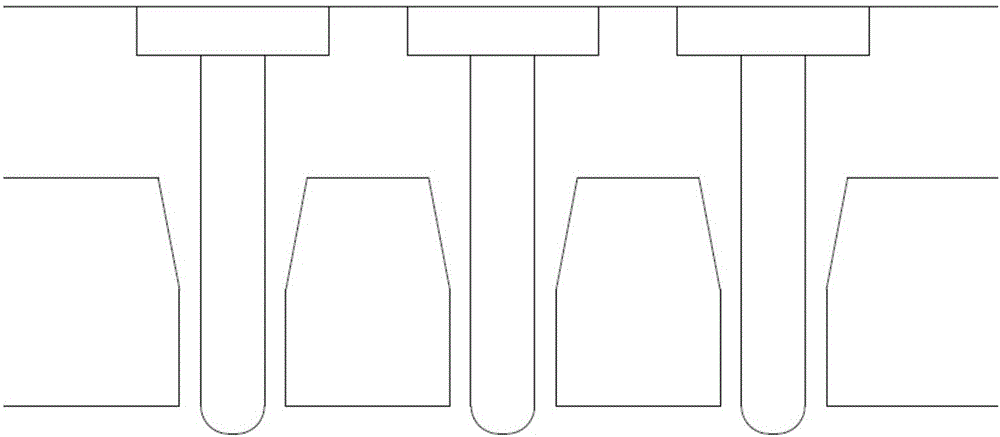

[0051] Welding pillars keep the stencil hole diameter at 0.70mm and thickness at 2.0mm, install the ceramic pillar grid array device on the stencil, and use the welding pillar grinding amount control frame to control the grinding amount, and its thickness is 0.2mm.

[0052] The method and tool of the invention effectively control various indicators of the column planting process of the CCGA717 device, and improve the process quality and consistency. After testing, the coplanarity of the welding post is controlled within 15-40 μm, the position of the welding post is controlled within 60-80 μm, the verticality of the welding post is controlled within 0.3-0.6°, and the qualified rate of post planting reaches 98.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com