A fully automatic production system for a non-woven fabric antibacterial master batch

An antibacterial masterbatch and production system technology, applied in coating and other directions, can solve the problems of pollution, waste of environment, inappropriate mixing and adding methods, etc., and achieve the effects of good dispersion, environmental protection of production process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with specific embodiment and accompanying drawing, the present invention is further described:

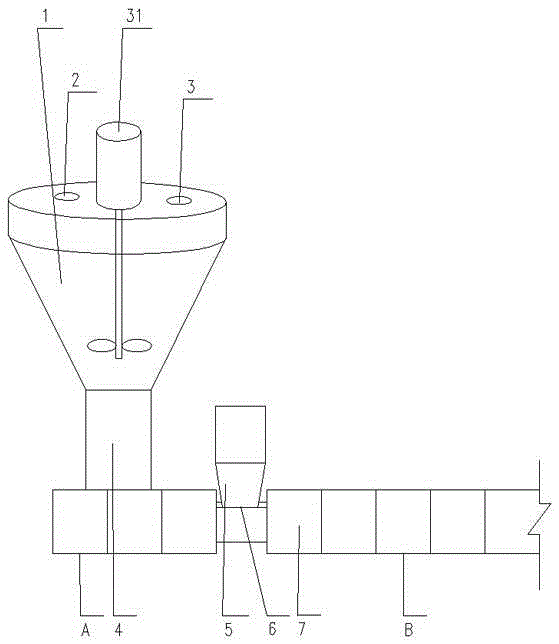

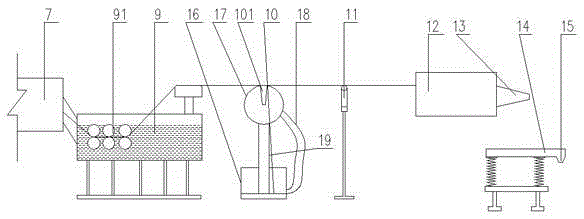

[0014] to combine figure 1 , 2 , 3, the non-woven antibacterial masterbatch automatic production system includes a hopper 1, an extruder 7, a raw material feeding port, a cooling water tank, and the like. The extruder 7 comprises a first extruder section A and a second extruder section B connected to the first extruder section.

[0015] The top of the hopper 1 is provided with a raw material feed port 3 and an auxiliary material feed port 2 . The bottom of the hopper 1 is connected with the mixing cabinet 4, the mixing cabinet 4 is connected with the first extruder section A, and the second extruder section B is connected with the cooling water tank 9, and a plurality of rollers are arranged in the cooling water tank, and the pair of rollers is in the shape of The word "one" is lined up.

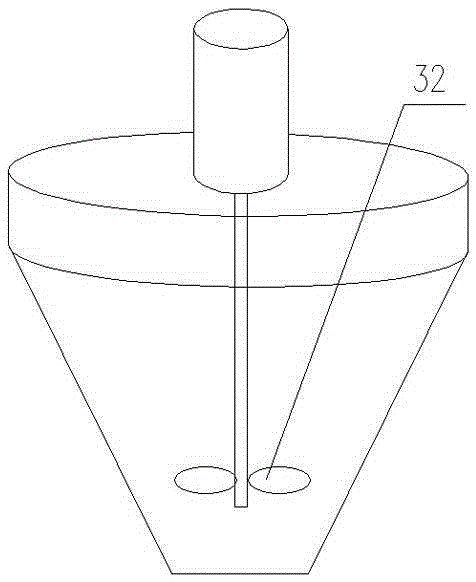

[0016] A stirring motor 31 is arranged on the top of the hopp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com