Optical fiber type ice binding state sensor

A technology combining status and sensors, applied in de-icing devices, transportation and packaging, aircraft parts, etc., can solve the problem that the icing sensor cannot be used to judge the combination status of the ice layer and the surface of the object, and achieve light weight and simple signal processing , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

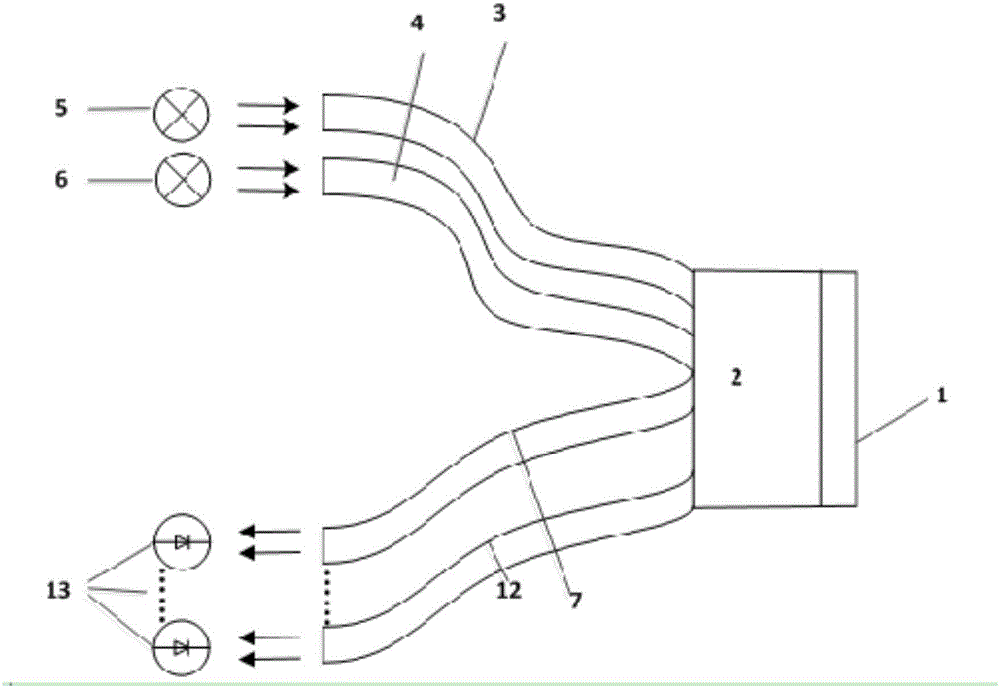

[0027] Embodiment one, as figure 1 As shown, the present embodiment includes 2 transmitting optical fiber bundles and 6 receiving optical fiber bundles. In the figure, the first transmitting optical fiber bundle 3, the second transmitting optical fiber bundle 4, the first receiving optical fiber bundle 7, and the second receiving optical fiber bundle One end of the optical fiber bundle, ..., the sixth receiving optical fiber bundle 12 is bundled into a concentrated optical fiber bundle in the metal casing 2, and its end face constitutes the detection end 1; Both are 2.5mm×3mm;

[0028] Adhesive glue is used between the 2 emitting optical fiber bundles and the 6 receiving optical fiber bundles in the metal shell 2; the other ends of the first emitting optical fiber bundle 3 and the second emitting optical fiber bundle 4 are respectively equipped with The infrared light-emitting diode 5 and the yellow light-emitting diode 6 with a peak wavelength of 590nm, and the other end of ...

Embodiment 2

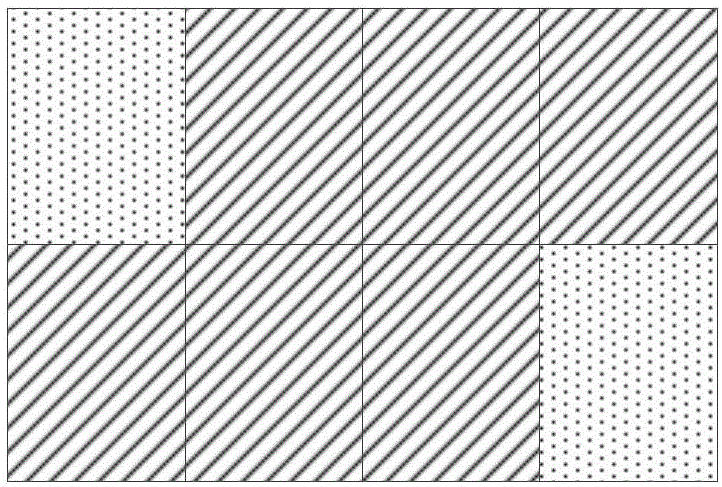

[0030] Embodiment 2. This embodiment includes 3 transmitting fiber bundles and 6 receiving fiber bundles. One end of the 3 transmitting fiber bundles and 6 receiving fiber bundles is bundled into a concentrated fiber bundle in a metal casing, and its end face constitutes a detection end; The cross-section of the optical fiber bundle and the receiving optical fiber bundle is a rectangle with the same area, and the size is 3.33mm×3mm;

[0031] Adhesive glue is used between the 3 emitting optical fiber bundles and the 6 receiving optical fiber bundles in the metal casing; the other ends of the 3 emitting optical fiber bundles are respectively equipped with infrared light-emitting diodes with a peak wavelength of 940nm and red light emitting diodes with a peak wavelength of 700nm. A light-emitting diode and a yellow light-emitting diode with a peak wavelength of 590nm, and a phototransistor is respectively installed at the other end of the 6 receiving fiber bundles.

[0032] In th...

Embodiment 3

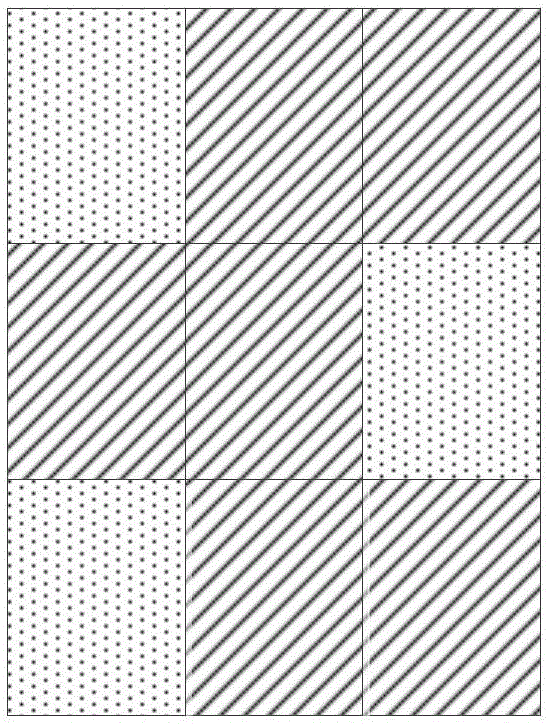

[0033] Embodiment 3. This embodiment includes 2 transmitting fiber bundles and 4 receiving fiber bundles. One end of the 2 transmitting fiber bundles and 4 receiving fiber bundles is bundled into a concentrated fiber bundle in a metal casing, and its end face constitutes a detection end; The cross-sectional area of the optical fiber bundle and the receiving optical fiber bundle is the same;

[0034] Adhesive glue is used between the 2 emitting optical fiber bundles and the 4 receiving optical fiber bundles in the metal shell; the other ends of the 2 emitting optical fiber bundles are respectively equipped with infrared light-emitting diodes with a peak wavelength of 940nm and yellow LEDs with a peak wavelength of 590nm. Light-emitting diodes, the other ends of the 4 receiving optical fiber bundles are respectively equipped with a photoelectric triode.

[0035] In this embodiment, the distribution of the 2 transmitting fiber bundles and the 4 receiving fiber bundles on the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com