Chlorinated polystyrene and its preparation method

A chlorinated polystyrene and polystyrene technology, applied in the chemical industry, can solve the problems of improving flame retardant properties, decreasing mechanical properties, threats to life and property safety, etc., and achieving good stability, good thermal stability, and high comprehensive performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

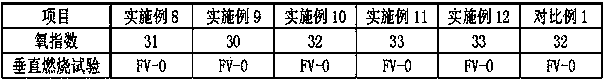

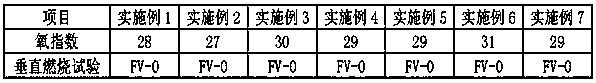

Examples

Embodiment 1

[0024] Take 1.5kg of polystyrene powder (weight-average molecular weight of 100,000, Mw / Mn of 2.5) and 10kg of water into the reaction kettle, add 50g of sodium lauryl sulfate, 40g of polyvinyl alcohol, and 75g of BPO, seal, stir and heat up To 70°C, feed chlorine gas from the bottom of the reactor and control the temperature to increase gradually, the temperature rise rate is 12°C / hour, the rate of chlorine flow is 200g / hour, the final reaction temperature is 105°C, the total amount of chlorine flow is 600g, and the total reaction time is 3 hours. After 3 times of alkali washing and 3 times of water washing, water-solid separation is carried out, and the solid product is dried at 50°C to obtain a finished product. The measured chlorine content is 16%, and the heating loss is 0.7%.

Embodiment 2

[0026] Take 1.5kg of polystyrene powder and 10kg of water into the reactor, add 50g of sodium chloride alkylsulfate, 40g of sodium polymethacrylate, and 75g of BPO respectively, seal it up, stir and heat up to 70°C, and feed it from the bottom of the reactor Chlorine and control the temperature to gradually increase, the heating rate is 12°C / hour, the rate of chlorine flow is 200g / hour, the final reaction temperature is 105°C, the total amount of chlorine flow is 600g, and the total reaction time is 3 hours. After 3 times of alkali washing and 3 times of water washing, water-solid separation is carried out, and the solid product is dried at 50°C to obtain a finished product. The measured chlorine content is 15.8%, and the heating loss is 0.6%.

Embodiment 3

[0028] Take 1.5kg of polystyrene powder (weight-average molecular weight of 100,000, Mw / Mn of 2.5) and 10kg of water into the reaction kettle, add 50g of sodium lauryl sulfate, 40g of polyvinyl alcohol, and 75g of BPO, seal, stir and heat up To 70°C, feed chlorine gas from the bottom of the reactor and control the temperature to increase gradually, the temperature rise rate is 12°C / hour, the rate of chlorine flow is 300g / hour, the final reaction temperature is 105°C, the total amount of chlorine flow is 900g, and the total reaction time is 3 hours. After 3 times of alkali washing and 3 times of water washing, water-solid separation is carried out, and the solid product is dried at 50°C to obtain a finished product. The measured chlorine content is 23%, and the heating loss is 0.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com