A low-smoke halogen-free flame-retardant ABS material for edge banding and its preparation method

An ABS material and edge banding technology, which is applied in the field of low-smoke halogen-free flame retardant ABS material for edge banding and its preparation, can solve the problems of edge banding, falling impact strength, affecting the physical and mechanical properties of ABS, etc. Achieve the effect of avoiding embrittlement, low production cost, and improving the effect of flame retardant and smoke suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

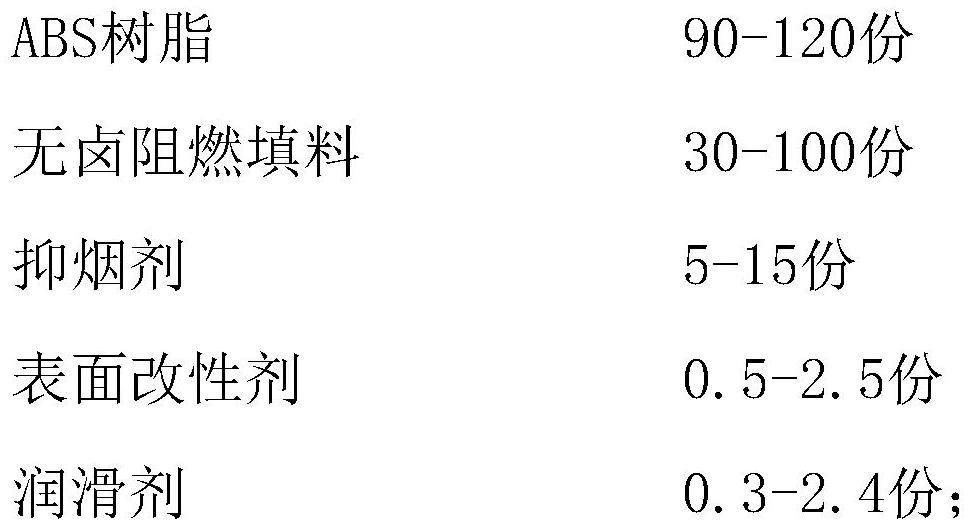

[0034] A low-smoke halogen-free flame-retardant ABS material for edge banding, comprising the following raw materials in parts by weight:

[0035]

[0036] Wherein, the mesh number of the halogen-free flame retardant filler is 8000 mesh.

[0037] The ABS resin is an ABS resin with a polybutadiene content of 30 wt %; the melt flow rate of the ABS resin is 50 g / min.

[0038] The halogen-free flame retardant filler is magnesium aluminum hydrotalcite.

[0039] The smoke suppressant is ferrocene.

[0040] The surface modifier is a silane coupling agent.

[0041] The silane coupling agent is KH550.

[0042] The lubricant is formed by mixing polyethylene wax and magnesium stearate at a weight ratio of 2:1.

[0043] The preparation method of the above-mentioned low-smoke halogen-free flame-retardant ABS material for edge banding comprises the following steps:

[0044] (S1), take raw material by weight, standby;

[0045] (S2), blend the halogen-free flame retardant filler, smo...

Embodiment 2

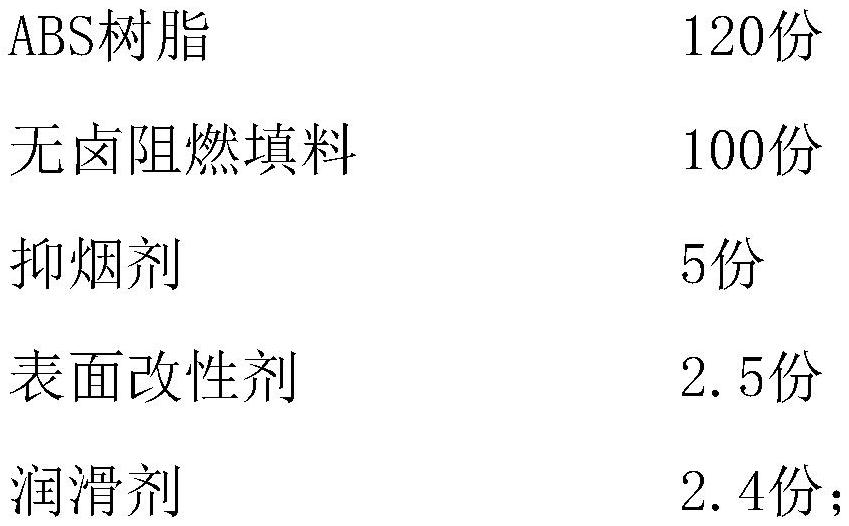

[0050] A low-smoke halogen-free flame-retardant ABS material for edge banding, comprising the following raw materials in parts by weight:

[0051]

[0052] Wherein, the mesh number of the halogen-free flame retardant filler is 7500 mesh.

[0053] The ABS resin is an ABS resin with a polybutadiene content of 29 wt %; the melt flow rate of the ABS resin is 48 g / min.

[0054] The halogen-free flame retardant filler is magnesium aluminum hydrotalcite.

[0055] The smoke suppressant is ferrocene.

[0056] The surface modifier is a silane coupling agent.

[0057] The silane coupling agent is KH560.

[0058] The lubricant is formed by mixing polyethylene wax and magnesium stearate at a weight ratio of 2:1.

[0059] The preparation method of the above-mentioned low-smoke halogen-free flame-retardant ABS material for edge banding comprises the following steps:

[0060] (S1), take raw material by weight, standby;

[0061] (S2), blend the halogen-free flame retardant filler, smo...

Embodiment 3

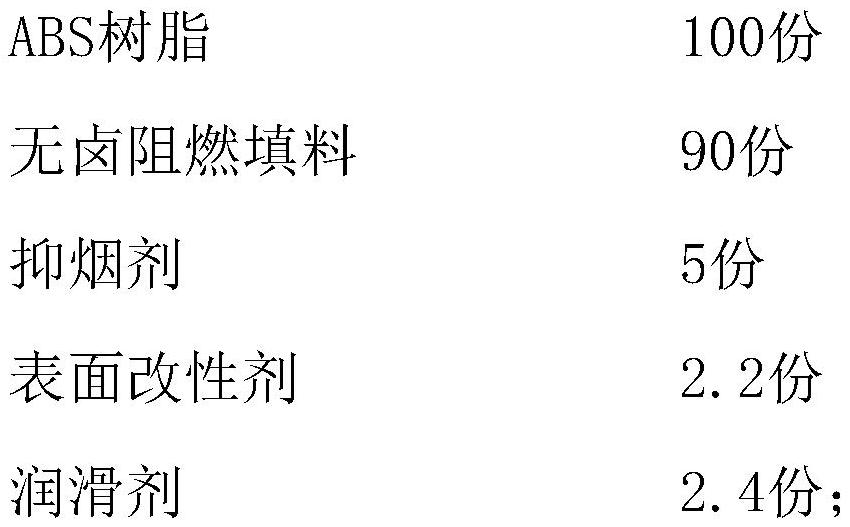

[0066] A low-smoke halogen-free flame-retardant ABS material for edge banding, comprising the following raw materials in parts by weight:

[0067]

[0068] Wherein, the mesh number of the halogen-free flame retardant filler is 10000 mesh.

[0069] The ABS resin is an ABS resin with a polybutadiene content of 28 wt %; the melt flow rate of the ABS resin is 45 g / min.

[0070] The halogen-free flame retardant filler is magnesium aluminum hydrotalcite.

[0071] The smoke suppressant is ferrocene.

[0072] The surface modifier is a silane coupling agent.

[0073] The silane coupling agent is KH570.

[0074] The lubricant is formed by mixing polyethylene wax and magnesium stearate at a weight ratio of 2:1.

[0075] The preparation method of the above-mentioned low-smoke halogen-free flame-retardant ABS material for edge banding comprises the following steps:

[0076] (S1), take raw material by weight, standby;

[0077] (S2), blend the halogen-free flame retardant filler, sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com