Carbon nano dot with adjustable light emission in visible-region whole spectral coverage and preparation method thereof

A full-spectrum, nano-dot technology, applied in the field of nano-materials, can solve the problem of adjusting the fluorescence emission of carbon nano-dots by the preparation method, and achieve the effect of solving the difficulty in regulating the emission band gap.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing carbon nano-dots with adjustable full-spectrum luminescence in the visible region, which is characterized in that it comprises the following steps:

[0026] dissolving citric acid and urea in a reaction solvent for solvothermal reaction to obtain carbon nanodots;

[0027] The reaction solvent includes one or more of water-miscible protic solvents and / or water-miscible aprotic solvents and water;

[0028] The mixing ratio of one or more of the water-miscible protic solvent and / or water-miscible aprotic solvent with water is 0-100%;

[0029] The mixing ratio of the water-miscible protic solvent and the water-miscible aprotic solvent is 0-100%.

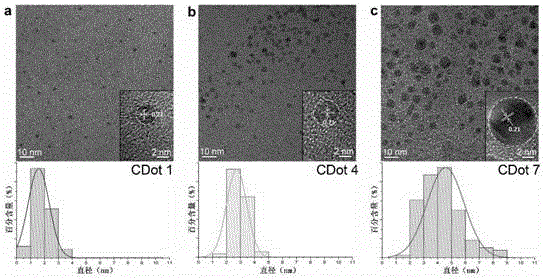

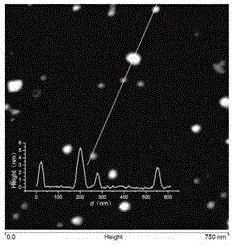

[0030] The present invention changes the polarity of the reaction solvent under solvothermal conditions by adjusting the mixing ratio of water and the protic and aprotic solvents that are miscible therewith, so as to prepare carbon nanodots with full-spectrum luminescence in the visib...

Embodiment 1

[0053] 3 g of citric acid and 6 g of urea were used as reaction raw materials (the mixing ratio of the reaction raw materials was 1:2), and were dissolved in 30 ml of reaction solvent to obtain a colorless and transparent solution. Wherein, the mixed solution of the reaction solvent water and DMF, wherein the volume ratio of water and DMF in the reaction solvent is reacted according to the ratio shown in Table 1.

[0054] Heat the colorless transparent solution in a steel-lined polytetrafluoroethylene reactor at 160° C. for solvothermal reaction for 4 hours to obtain a reaction mixture;

[0055] The reaction mixture was mixed with 60 milliliters of ethanol, and centrifuged at a speed of 8000 rpm for 5 minutes; the upper layer liquid was removed (removing residual reactant and reaction solvent), and the precipitate was dissolved in 60 milliliters of ethanol and centrifuged 3 times, Until the upper liquid is relatively clear, the precipitate is taken and freeze-dried at -50°C fo...

Embodiment 2

[0061] 3 g of citric acid and 3 g of urea were used as reaction raw materials (the mixing ratio of the reaction raw materials was 1:1), and dissolved in 30 ml of reaction solvent to obtain a colorless and transparent solution. Wherein, the mixed solution of the reaction solvent water and DMF, wherein the volume ratio of water and DMF in the reaction solvent is reacted according to the ratio shown in Table 2.

[0062] Heat the colorless transparent solution in a steel-lined polytetrafluoroethylene reactor at 160° C. for solvothermal reaction for 4 hours to obtain a reaction mixture;

[0063] The reaction mixture was mixed with 60 milliliters of ethanol, and centrifuged at a speed of 8000 rpm for 5 minutes; the upper layer liquid was removed (removing residual reactant and reaction solvent), and the precipitate was dissolved in 60 milliliters of ethanol and centrifuged 3 times, Until the upper liquid is relatively clear, the precipitate is taken and freeze-dried at -50°C for 36 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com