Wear-resisting material used for brake disc of high-speed train and preparation method for wear-resisting material

A technology of wear-resistant materials and high-speed trains, applied in the field of alloy steel materials, can solve the problems of obvious changes in friction coefficient with load and temperature, poor structure uniformity of as-cast brake disc materials, complicated preparation process, etc., to shorten the heat treatment cycle, Effect of improving tissue uniformity and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

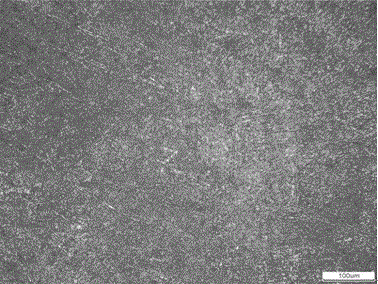

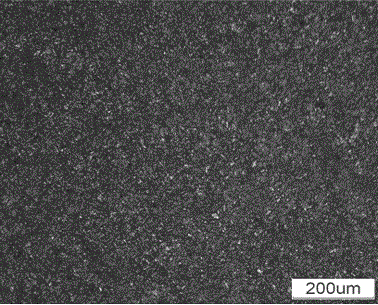

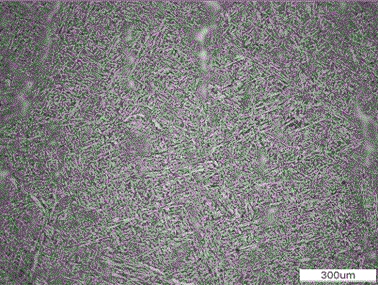

[0028] Weigh the sample as described in Table 1 above, use a 50Kg medium frequency induction furnace to melt the molten steel, add ferro-titanium and pure niobium, adjust the chemical composition of the molten steel, and then pour it. The as-cast sample was obtained by sand casting, and the metallographic structure of the as-cast sample is shown in figure 1 . Specimens for wire cutting heat treatment. The as-cast sample was heated to 900°C for 2 hours, water quenched, then kept at 600°C for 2 hours, and air-cooled. The metallographic structure of the sample after heat treatment is shown in figure 2 .

[0029] See Table 2 for the volumetric wear rates of the as-cast and heat-treated samples in Example 1 above under the conditions of a load of 100 N and a sliding speed of 45 m / s.

[0030] Table 2 Volume wear rate of as-cast and heat-treated states

[0031]

Embodiment 2

[0033] Weigh the sample as described in Table 1 above, use a 50Kg intermediate frequency induction furnace to melt the molten steel, add ferrotitanium, and adjust the alloying elements of the molten steel for pouring. The as-cast samples were obtained by sand casting, and the samples for heat treatment were processed by wire cutting. The as-cast sample was heated to 950°C for 1.5 hours, water quenched, then kept at 550°C for 1.5 hours, and air-cooled.

[0034] Under the same conditions, the friction coefficient of alloy steel is maintained at 0.35~0.40, and the volume wear rate is 3.45mm 3 / m.

Embodiment 3

[0036] Weigh the samples as described in Table 1 above, use a 50Kg medium frequency induction furnace to melt the molten steel, add pure niobium, adjust the chemical composition of the molten steel, and then pour. The as-cast samples were obtained by sand casting, and the samples for heat treatment were processed by wire cutting. The as-cast sample was heated to 1000°C for 1 hour, water quenched, then kept at 650°C for 2.5 hours, and air-cooled.

[0037] Under the same conditions, the friction coefficient of alloy steel is maintained at 0.33~0.37, and the volume wear rate is 2.96mm 3 / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com