Surface-modified magnesium alloy material with good corrosion resistance and biocompatibility, preparation method and application thereof

A biocompatibility and surface modification technology, applied in metal material coating process and other directions, can solve the problems of fast degradation rate of magnesium alloys and insufficient surface cytocompatibility, achieve good cytocompatibility, and is conducive to Adhesion and corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Clean the JDBM magnesium alloy sheet with a thickness of 1mm and a length and width of 10mm with alcohol, deionized water and ultrasonic cleaning successively, each time for 15 minutes. The pH value in 50 ml of ultrapure water was adjusted to 10 with 1 mol / L sodium hydroxide, and the solution was used as a hydrothermal medium. The degree of filling of the reactor was 35%. The hydrothermal temperature is 120°C, and the time is 8h. After the hydrothermal treatment, the samples were scrubbed with copious amounts of deionized water.

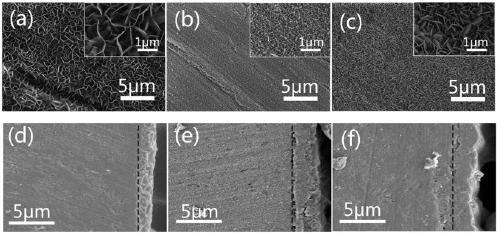

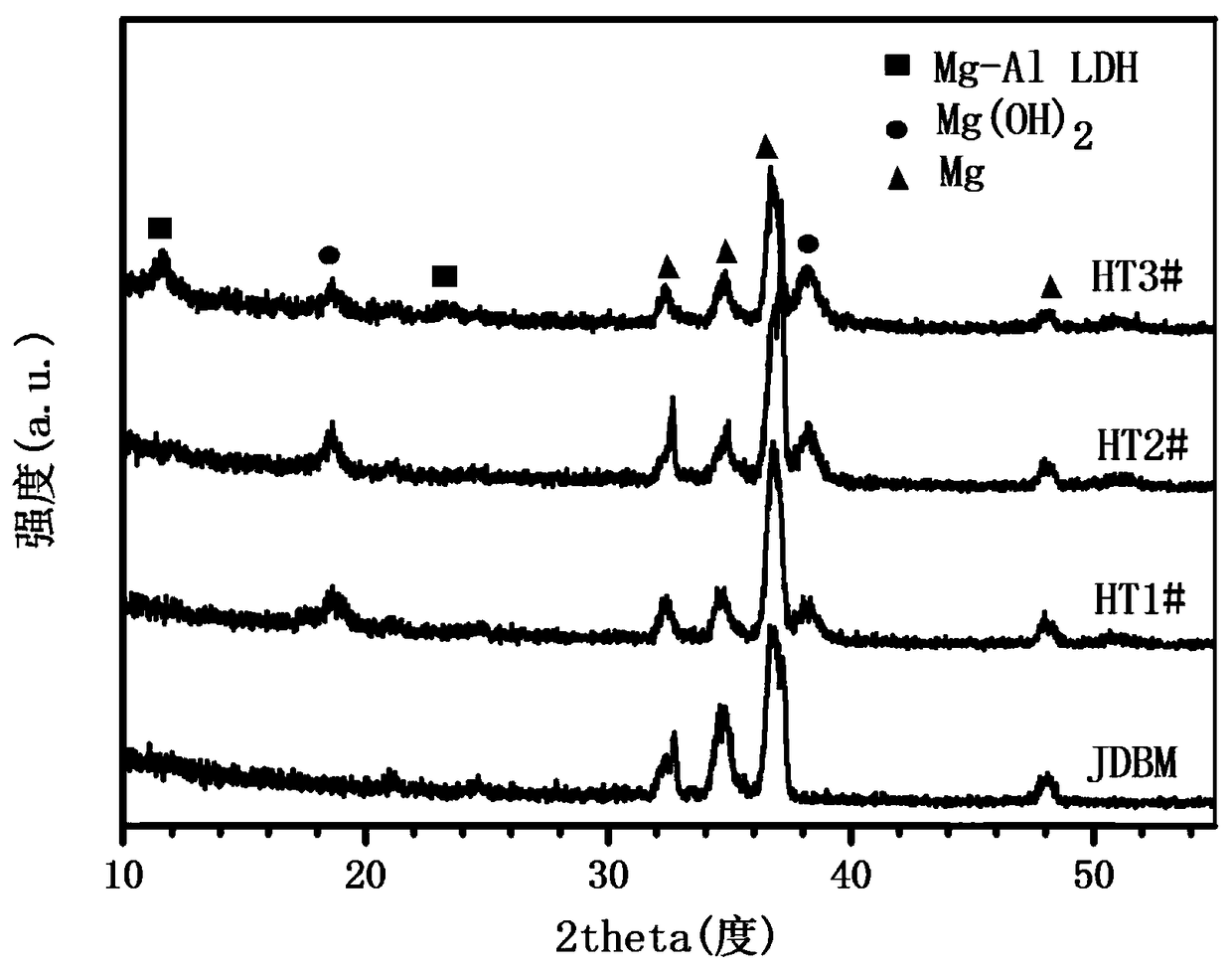

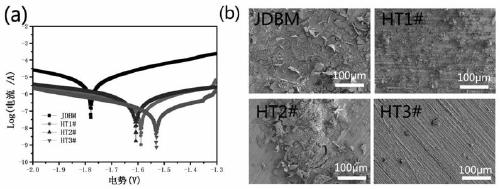

[0044] Referring to the magnesium alloy scanning electron microscope picture ( figure 1 (a)) and cross-sectional pictures ( figure 1 (d)), it can be seen that the treated surface is a sheet-like nanostructure, the thickness of the nanosheets is about 20 nm, and the distribution is uniform, and the thickness of the coating is about 1.8 μm. figure 2 HT1# is the XRD spectrogram of the material surface obtained by the modification treatment i...

Embodiment 2

[0046] Clean the JDBM magnesium alloy sheet with a thickness of 1mm and a length and width of 10mm with alcohol, deionized water and ultrasonic cleaning successively, each time for 15 minutes. The pH value in 50 milliliters of ultrapure water was adjusted to 12 with 1 mol / L sodium hydroxide, and the filling degree of the reaction kettle was 35%. Carry out hydrothermal treatment afterwards, its specific process parameter is as described in embodiment 1. .

[0047] Refer to the scanning electron microscope pictures ( figure 1 (b)) and cross-sectional pictures ( figure 1 (e)), it can be seen from the figure that the treated surface is a sheet-like nanostructure, the thickness of the nanosheets is about 20nm, and the distribution is uniform, and the thickness of the coating is about 2.3μm. figure 2 HT1# is the XRD spectrum of the surface of the material obtained through the modification in Example 2. After the modification in this Example, the main crystal phase composition on...

Embodiment 3

[0049] Clean the JDBM magnesium alloy sheet with a thickness of 1mm and a length and width of 10mm with alcohol, deionized water and ultrasonic cleaning successively, each time for 15 minutes. The pH value of the 0.02 mol / L aluminum nitrate in 50 ml was adjusted to 12 with 10 mol / L sodium hydroxide. The degree of filling of the reactor was 35%. Carry out hydrothermal treatment afterwards, its specific process parameter is as described in embodiment 1.

[0050] Referring to the magnesium alloy scanning electron microscope picture ( figure 1 (c)) and cross-sectional pictures ( figure 1 (f)), it can be seen from the figure that the treated surface is a sheet-like nanostructure, the thickness of the nanosheets is about 20nm, and the distribution is uniform, and the thickness of the coating is about 2μm. figure 2 Among them, JDBM and HT3# are the XRD spectrum patterns of the material surface obtained without any treatment and the modified treatment of the present embodiment 3 r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com