A kind of colored flame-retardant water-repellent silk fabric and its preparation method

A technology of real silk fabric and water silk, which is applied in the field of textiles, can solve the problems of large amount of chemicals and difficulty in retaining the luster and natural style of silk, and achieve soft luster, easy operation and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

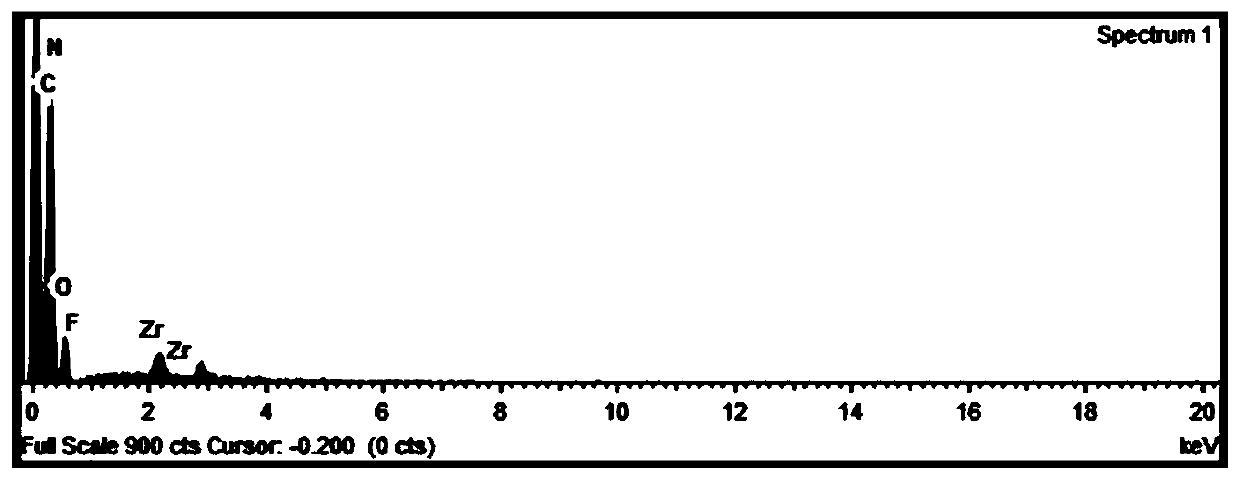

[0029] 36g / m 2 The Lianbai electric spinning (electric spinning is a kind of silk fabric) is immersed in 1g / L dopamine aqueous solution, shaken at 35°C for 25 hours, the fabric is taken out, washed with water, and dried to obtain brown electric spinning. Soak the brown electric spinning in 1g / L potassium fluozirconate aqueous solution, shake it at 50°C for 5 hours, take it out, rinse it with water, and dry it to obtain a brown flame-retardant and water-repellent electric spinning.

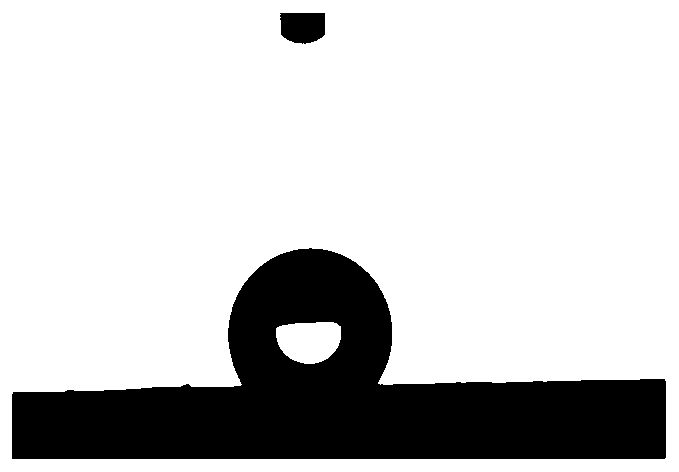

[0030] According to the oxygen index method of GB / T5454-1997 textile combustion performance test, the oxygen index of the brown flame-retardant and water-repellent electric spinning prepared in this embodiment is 27.6%, while the oxygen index of the whitening electric spinning that has not been treated by the method of this embodiment The index was 23.2%. attached figure 1 It is the surface morphology of Lianbai electric spinning before and after treatment. figure 1 (a) It can be seen that the f...

Embodiment 2

[0032] 36g / m 2 The Lianbai electric spinning was dipped in a 1.5g / L dopamine aqueous solution, shaken at 40°C for 26 hours, the fabric was taken out, washed with water, and dried to obtain a brown electric spinning. Soak the brown electric spinning in 1.5g / L potassium fluozirconate aqueous solution, shake it at 60°C for 8 hours, take it out, rinse it with water, and dry it to obtain a brown flame-retardant and water-repellent electric spinning.

[0033] According to the oxygen index method of GB / T5454-1997 textile combustion performance test, the oxygen index of the brown flame-retardant and water-repellent electric spinning prepared in this example is 28.2%, while the oxygen index of the silk electric spinning that has not been treated by the method of this example is 23.2%. attached Figure 4 It is the surface morphology of the brown flame-retardant and water-repellent electric spinning prepared in this example before and after washing. The washing condition is 50°C for 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com