Match gate process engine

An engine, two-stroke technology, applied in the direction of engine components, combustion engines, engine cooling, etc., can solve the problems of large heat load, difficulty in practical use, engine pollution and emission, etc., and achieve the effect of low pollution and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

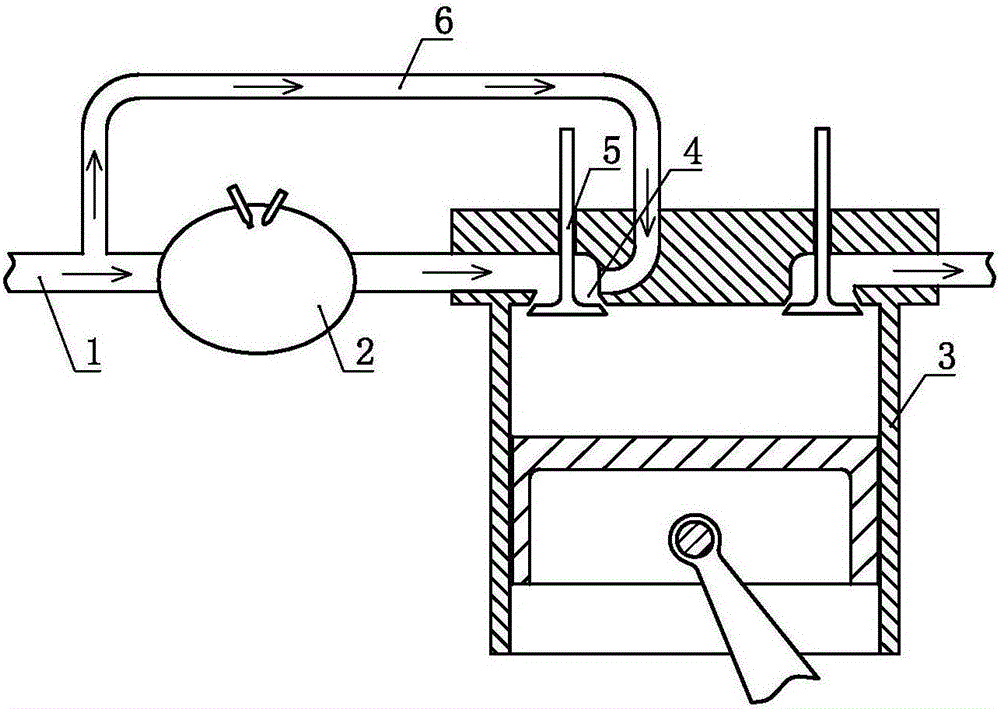

[0043] A homologous process engine such as figure 1 As shown, it includes a working medium passage 1, a combustion chamber 2 and a cylinder-piston mechanism 3, an air charging port 4 is set on the cylinder-piston mechanism 3, an air charging control device 5 is set at the charging port 4, and the working medium passage 1 The combustion chamber 2 is then communicated with the cylinder of the cylinder-piston mechanism 3 through the charging control device 5 and the charging port 4; And the charging port 4 communicates with the cylinder of the cylinder-piston mechanism 3 .

Embodiment 2

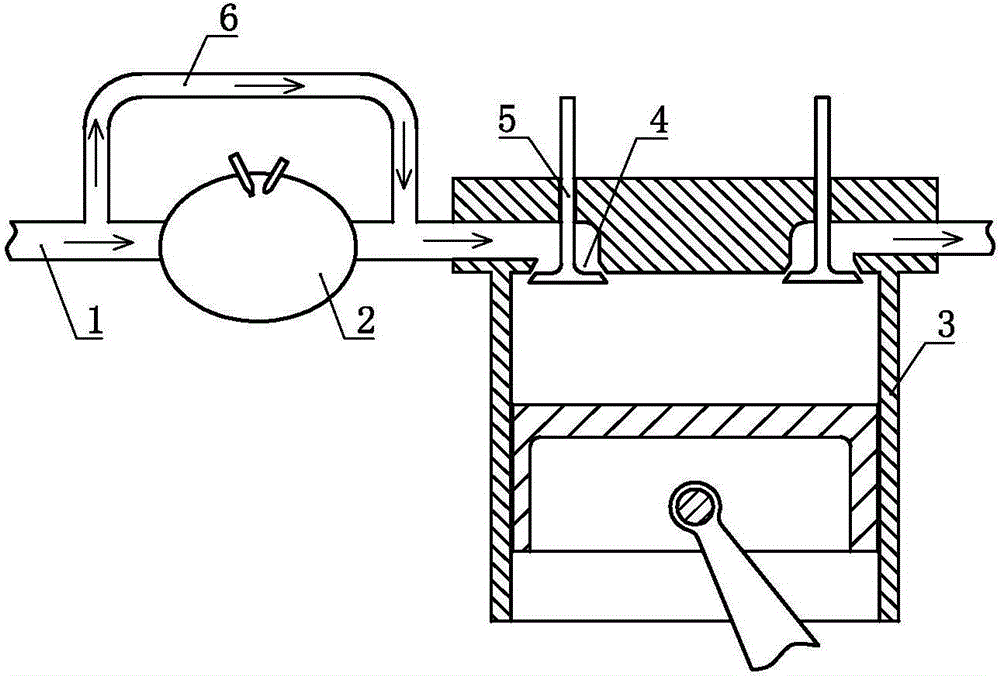

[0045] A homologous process engine such as figure 2 As shown, the difference from Embodiment 1 is that the working medium channel 1 communicates with the fluid channel between the combustion chamber 2 and the gas charging port 4 via a bypass channel 6 .

[0046] As a changeable implementation mode, both Embodiment 1 and Embodiment 2 of the present invention can further selectively choose to make the cylinder-piston mechanism 3 according to the combustion chamber inflation expansion power stroke-exhaust stroke-bypass channel inflation expansion power stroke- The four-stroke working mode of the exhaust stroke works, or the cylinder-piston mechanism 3 is inflated and expanded in accordance with the two-stroke thermal process of the N combustion chambers, and the power stroke-exhaust stroke is then performed in M bypass channels. In the composite working mode of the two-stroke cold process of the gas stroke, the M and the N are both non-zero integers.

[0047] As a convertible e...

Embodiment 3

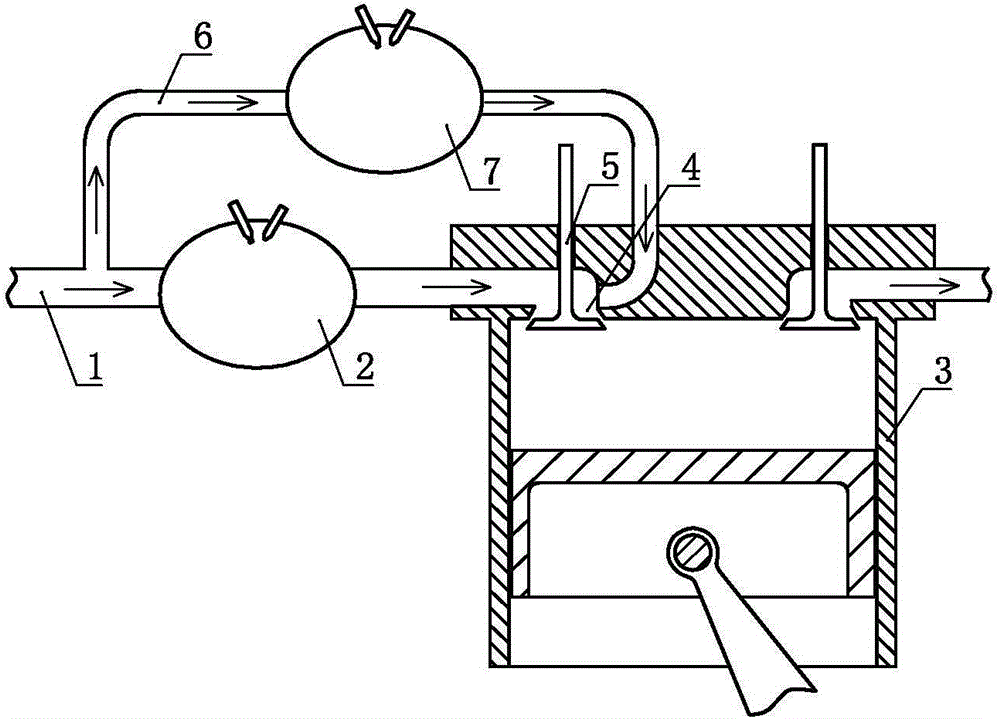

[0049] A homologous process engine such as image 3 As shown, on the basis of Embodiment 1, an auxiliary combustion chamber 7 is further provided on the bypass channel 6 .

[0050] As a changeable embodiment, the embodiment 2 of the present invention and its changeable form and the changeable form of embodiment 1 can further provide an auxiliary combustion chamber 7 on the bypass channel 6 .

[0051] As an alternative embodiment, Embodiment 3 of the present invention and its alternative implementations can further selectively choose to make the combustion chamber 2 and the auxiliary combustion chamber 7 combust alternately or make the combustion chamber 2 and the auxiliary combustion chamber 7 One of the auxiliary combustion chambers 7 is set as a continuous combustion chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com