Air source heat pump defrosting and deashing device and method based on shock wave and heat pipe technologies

A technology of air source heat pump and ash cleaning device, applied in the direction of cleaning heat transfer device, heat pump, high-efficiency regulation technology, etc., can solve the problems of deteriorating heat transfer effect of heat exchanger, increasing surface heat transfer resistance, increasing air flow resistance, etc. , to achieve the effect of good cleaning, maintenance, and rapid dissemination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

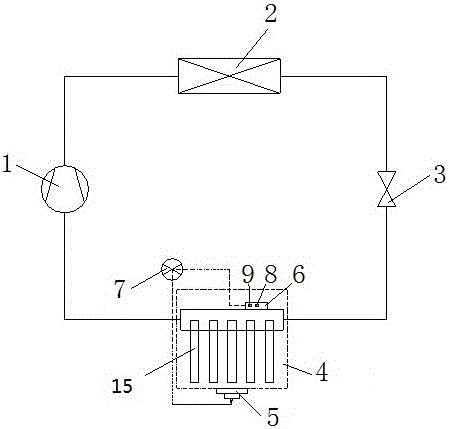

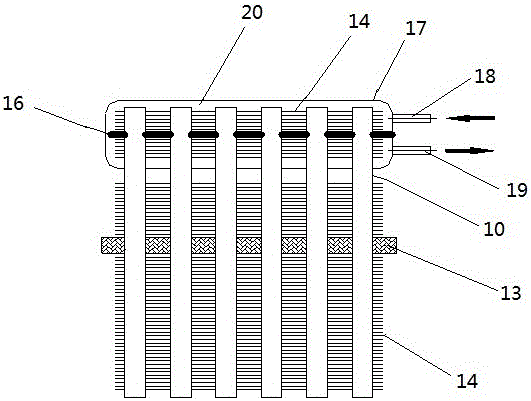

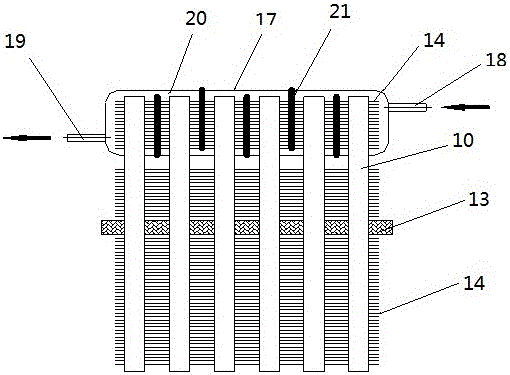

[0035] See attached Figure 1-7

[0036] 1. Parameter setting: separately set the surface temperature of the outdoor heat pipe heat exchanger 4, the thickness of the surface frost layer, the cleaning time, the frost cleaning time, the pressure of the air shock wave generator 5, the inflow and outflow speed of the refrigerant, and the refrigerant cycle The time parameter is set in the controller 7 as a standard comparison parameter.

[0037]2. Cooling mode: start the compressor 1, the high-temperature and high-pressure refrigerant gas is discharged through the compressor 1, enters the outdoor heat pipe heat exchanger 4, passes through the heat pipe group 15 installed on the fixed bracket 13, and the header pipe 17 and heat exchange fins The fins 14 exchange heat with the outside air. The refrigerant 20 flows in from the refrigerant inlet pipe 18, and exchanges heat through the heat exchange fins 14 installed on the heat pipe 10 in the header pipe 17 and separated by the inter...

Embodiment 2

[0040] See attached Figure 1-7

[0041] 1. Parameter setting: separately set the surface temperature of the outdoor heat pipe heat exchanger 4, the thickness of the surface frost layer, the cleaning time, the frost cleaning time, the pressure of the air shock wave generator 5, the inflow and outflow speed of the refrigerant, and the refrigerant cycle The time parameter is set in the controller 7 as a standard comparison parameter.

[0042] 2. Heating mode: start the compressor 1, the high-temperature and high-pressure refrigerant 20 gas is discharged through the compressor 1, enters the indoor heat exchanger 2, condenses into a low-temperature and high-pressure liquid, and is throttled by the throttling device 3 before entering the outdoor The heat pipe heat exchanger 4 exchanges heat with the outdoor air through the heat pipe group 15 installed on the fixed bracket 13 , as well as the header pipe 17 and the heat exchange fins 14 . For the inside of the heat pipe, the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com