X-ray grazing-incidence reflecting-mirror effective area calibration method

A technology of effective area and calibration method, which is applied in the field of X-ray optics, can solve problems such as low precision, poor parallelism, and difficulty in obtaining it, and achieve the effects of good collimation, lightened operation burden, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

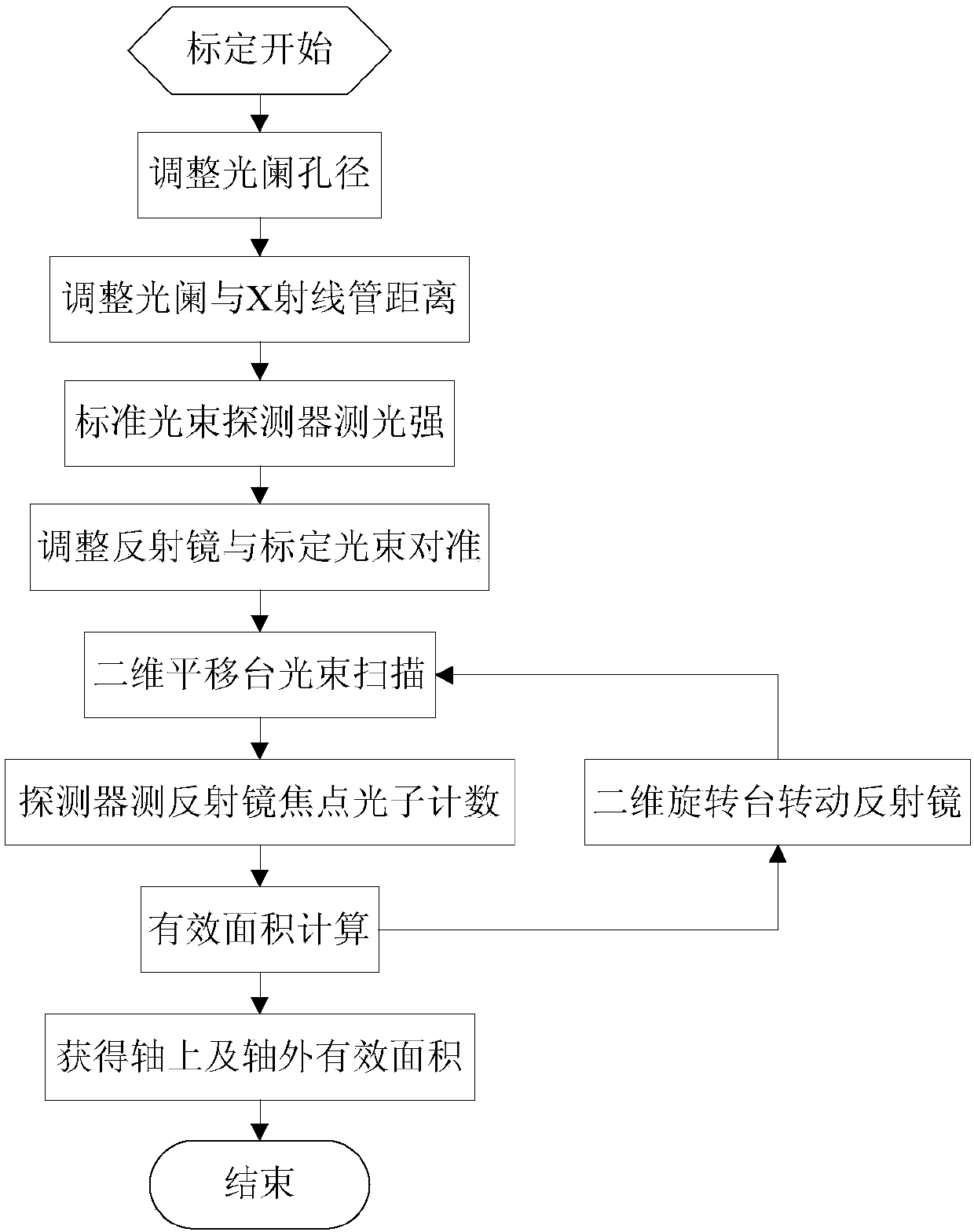

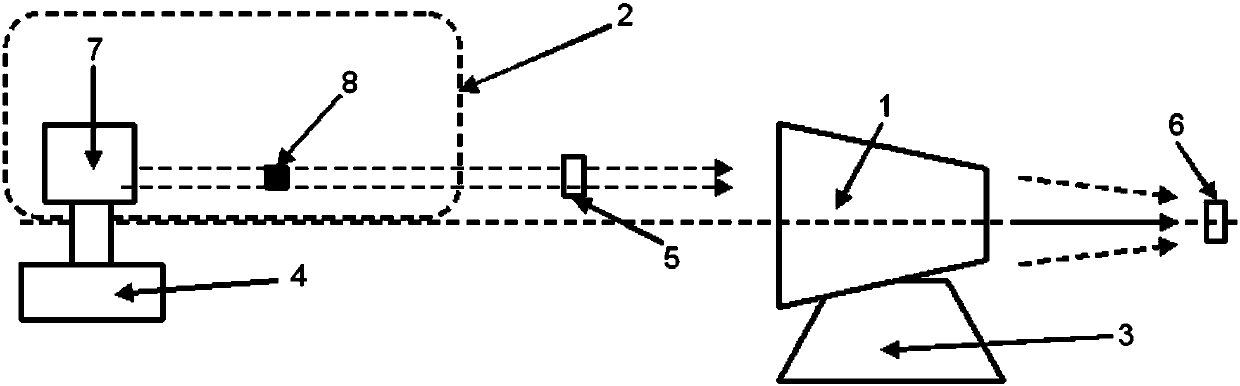

[0035] Such as Figure 1~2 As shown, a method for calibrating the effective area of an X-ray grazing incidence mirror includes an X-ray grazing incidence mirror 1, a narrow beam X-ray source 2, a two-dimensional rotating stage 3, a two-dimensional translation stage 4, a calibration beam detector 5 and mirror focus detector 6; the X-ray grazing incidence mirror 1 is installed on the two-dimensional rotating table 3, and is used to adjust the pitch and deflection biaxial attitude of the X-ray grazing incidence mirror 1, and the narrow beam X-ray source 2 is installed on two On the three-dimensional translation platform 4, it is used to realize the biaxial movement of the narrow-beam X-ray source 2, and then complete the scanning of the grazing incidence mirror 1. The calibration beam detector 5 is installed between the narrow-beam X-ray s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com