Method for production of additives enhancing water tightness of building materials

A building material and watertight technology, applied in chemical instruments and methods, cement mixing devices, mixers with rotating stirring devices, etc., can solve the problems of increasing the specific gravity of the product, large particle size of the product, and long drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation of the additive material according to the invention is based on the knowledge that burnt lime, as a traditional component of mortar in the construction industry, undergoes a gelation process under the action of carbon dioxide in the air and forms CaCO 3 , by using a hydrophobic additive with a low relative density it is possible to mix burnt lime with a hydrophobic agent in the burnt lime itself. According to our research, suitable additives are vegetable oils, such as sunflower oil, rapeseed oil, palm oil, etc.

[0031] However, mixtures of vegetable oils with CaO and water form coarse dispersions and are not suitable for use in construction. Because vegetable oil is a fatty acid ester of glycerol, and glycerol (glycerol) is an alcohol containing three hydroxyl groups, that is, vegetable oil is a fatty acid ester of three oils, in most cases, one fatty acid molecule blocks glycerol All three hydroxyl groups of the triol, acid saturation and chain lengt...

Embodiment 1

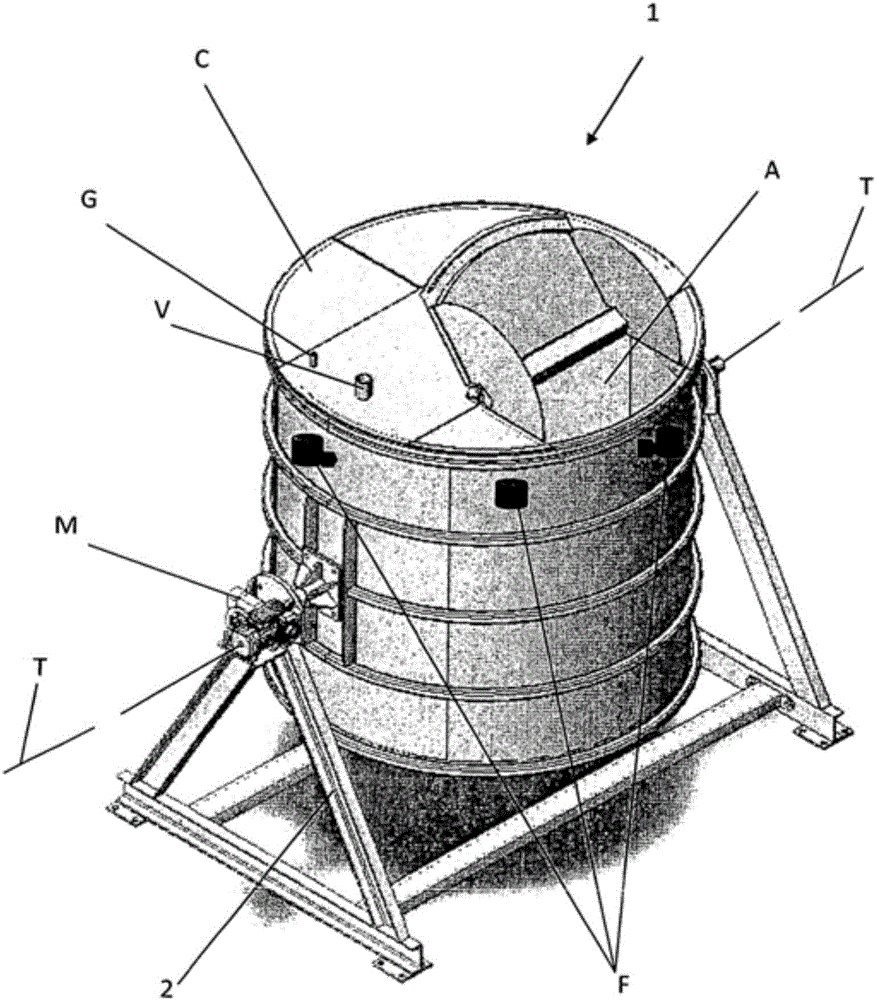

[0054] The CaO of 40kg is put into the container C of powder mixing equipment 1 as base material, and the CaO of 40kg is about 45wt% of the raw material used in the reaction process. During operation of the powder mixing plant 1 , ie during continuous mixing operation, a mixture of 2 wt % ethanol and 0.1 wt % methanol is sprayed through nozzle F into container C based on the total mass of quicklime charged. Then, also by fine spraying, a hydrophobizing agent comprising 12% by weight of the raw materials used in the process and having the following composition was introduced into container C:

[0055] - 60% by weight of sunflower oil;

[0056] - 39.9 wt% ethanol;

[0057] - 0.1% by weight of methanol.

[0058] After the additions have been uniformly mixed, within 2-3 seconds, 46 liters of water (instead of about 13 L), comprising about 52 wt% of all contents in container C (i.e. a large chemical overmetering). After the chemical reaction starts, the powder mixing device 1 i...

Embodiment 2

[0065] The CaO of 40kg is put into the container C of powder mixing equipment 1 as base material, and the CaO of 40kg is about 45wt% of raw material used in the reaction process. During operation of the powder mixing plant 1 , ie during continuous mixing operation, a mixture of 3 wt % ethanol and 0.2 wt % methanol is sprayed through nozzle F into container C based on the total mass of quicklime charged. Then, a hydrophobic agent comprising 8% by weight of the raw materials used in the process and having the following composition was also introduced into container C by fine spraying:

[0066] - 60% by weight of sunflower oil;

[0067] - 38 wt% ethanol;

[0068] - 2% by weight of methanol.

[0069] After the additions have been uniformly mixed, within 2-3 seconds, 12 liters of water comprising about 26% by weight of the total content in vessel C (ie less than stoichiometric ratio) are added with stirring. After the vigorous chemical reaction starts, stop the equipment powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com