Method and apparatus for controlled alignment and deposition of branched electrospun fiber

An electrospinning and fiber technology, applied in the field of polymer fiber production, can solve problems such as methods and devices for separating continuous single fiber threads that have not yet been solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] simply put:

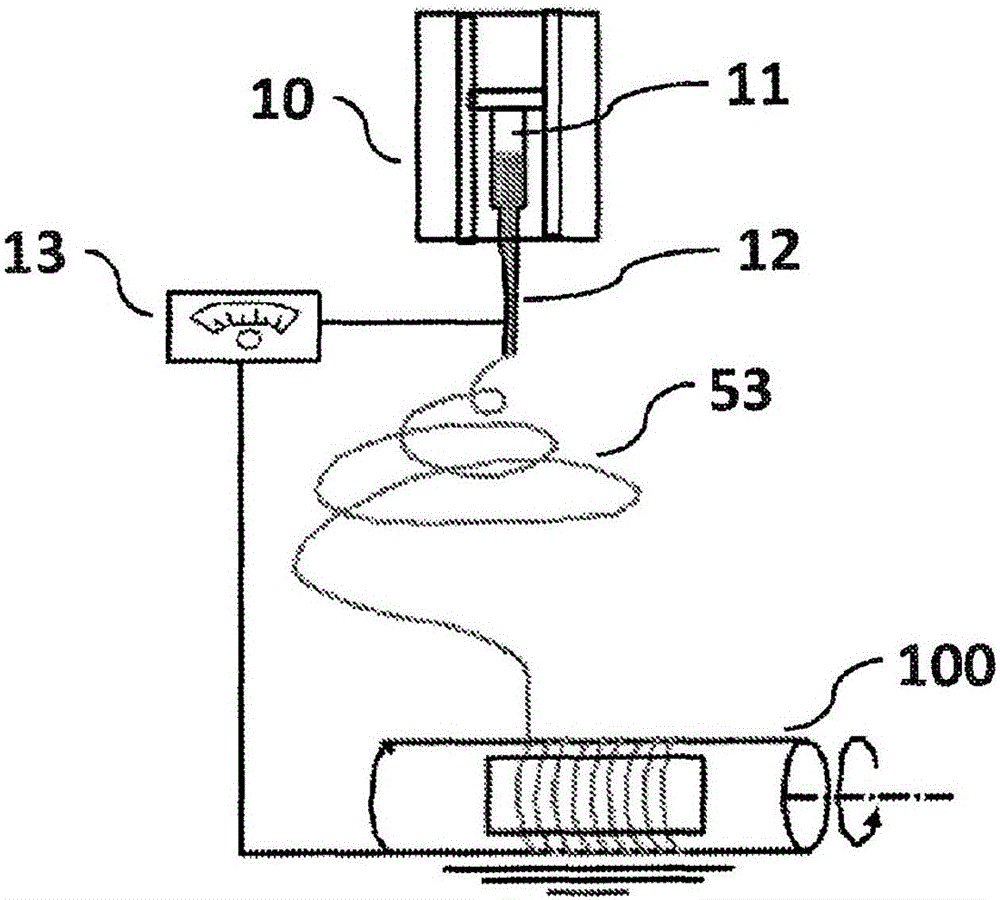

[0031] figure 1 is a non-limiting diagram schematically illustrating a typical electrospinning process. A typical electrospinning setup consists of a syringe pump, a syringe with a needle, a high voltage power supply, and a collector. Currently, a single rotating or flat target disk, a pair of charged collector bars, has been used as a fiber collector.

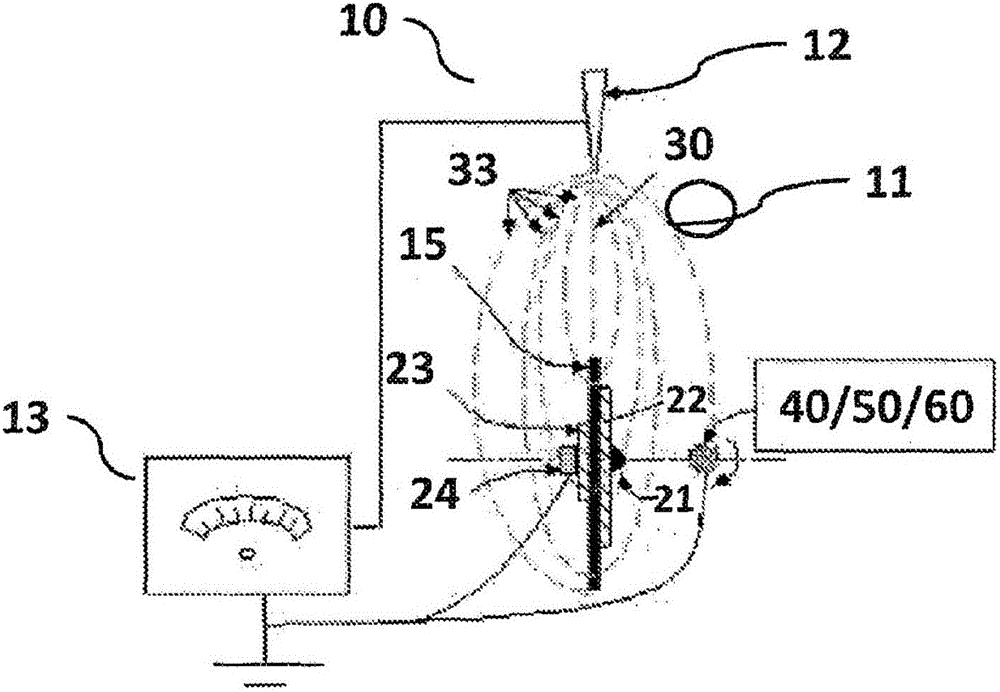

[0032] figure 2 is a non-limiting diagram schematically illustrating the method of the invention. The embodiment shown in the diagram uses the path of the electromagnetic field generated by the potential difference between the charged needle and the rotating auxiliary metal disk obtained using a high powered voltage source to capture, deposit and orient the fibers on the substrate. The device shown includes a syringe needle, DC motor, blunt bolt, and front insulating washer. Use a linear gantry to reciprocate the collector.

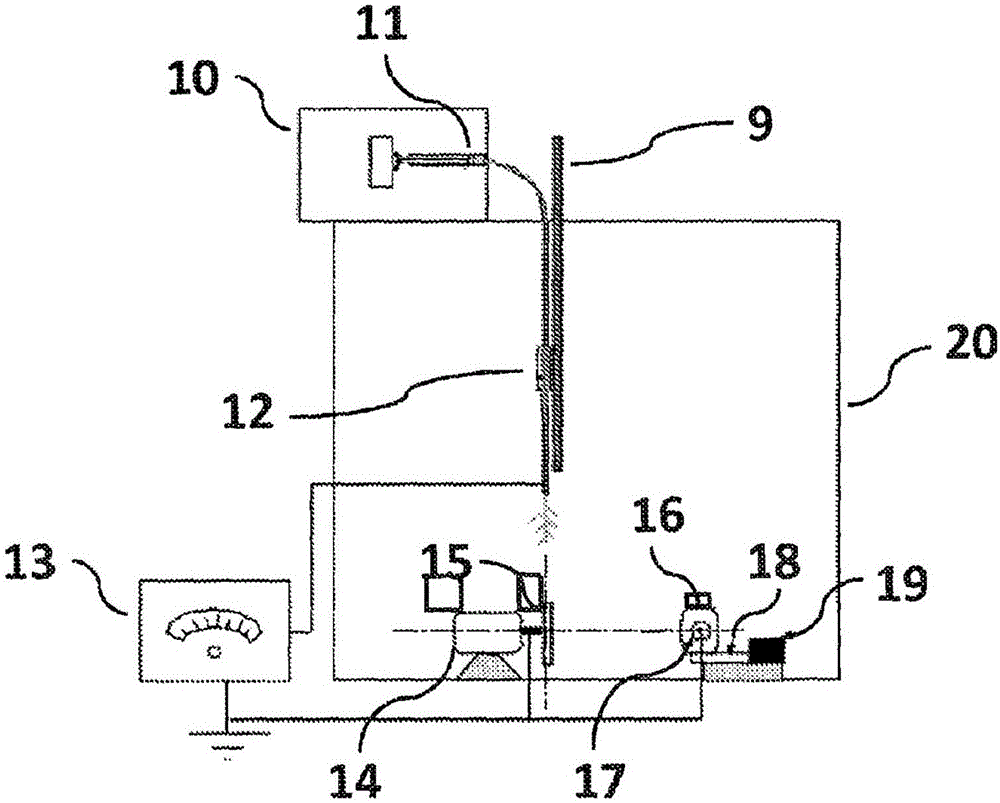

[0033] image 3 is a non-limiting diagram illustrating components of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com