Black rice-white peach flavor yoghourt and preparation method thereof

A technology of black rice and white peach, applied in the field of dairy and beverage processing, can solve the problems of unreasonable addition of meal replacement yogurt and cereals, inability to guarantee edible quality, poor storage and transportation of peach fruit, etc., so as to inhibit the growth of cancer cells and improve iron deficiency. anemia, reducing vascular fragility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

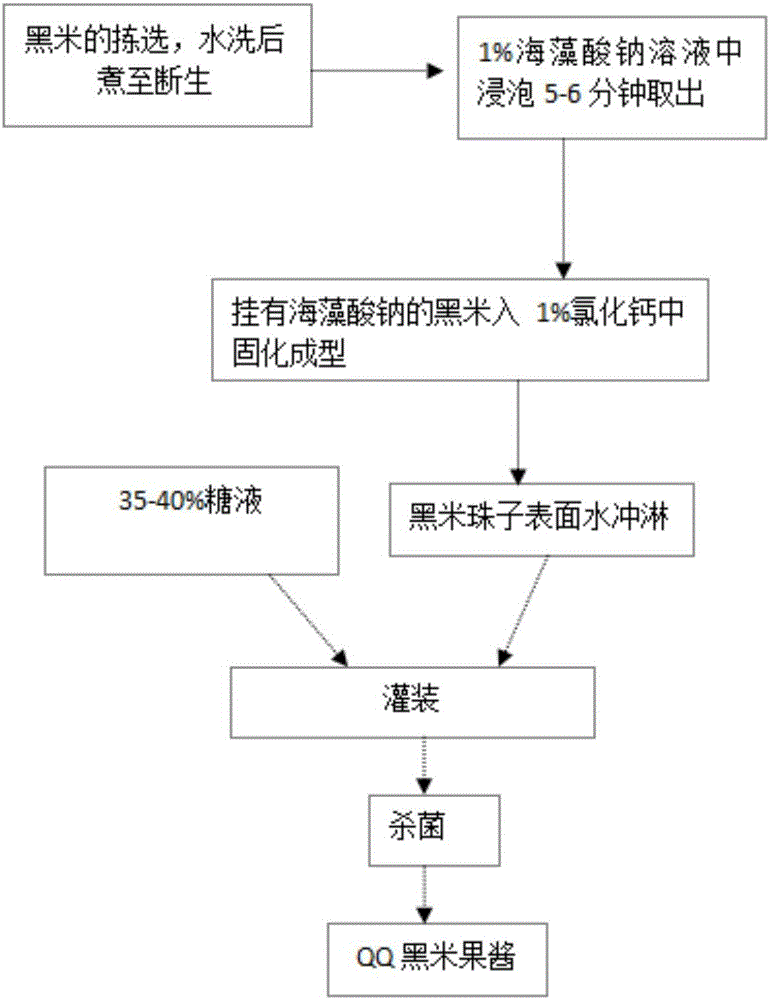

Method used

Image

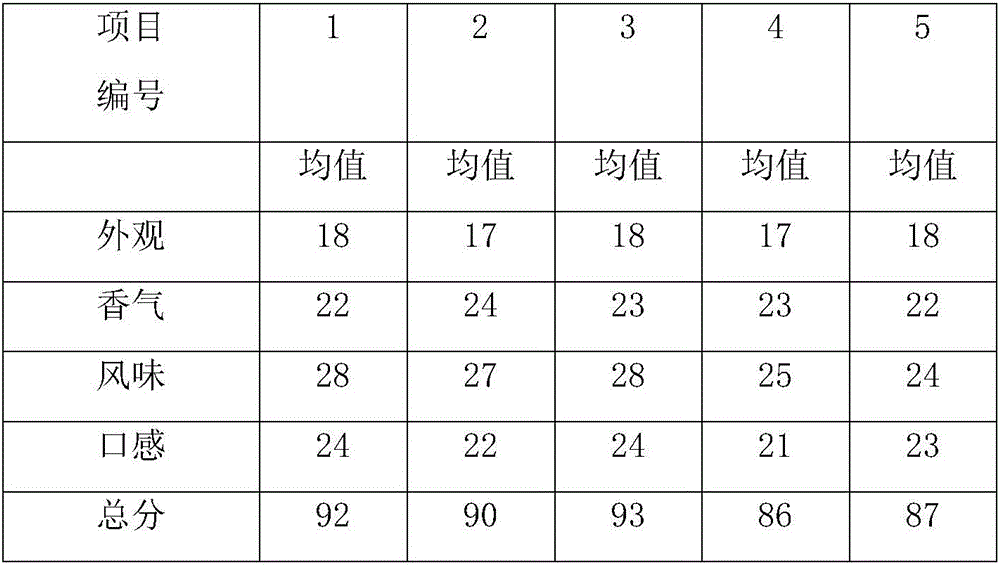

Examples

Embodiment 1

[0033] A method for preparing black rice and white peach flavored yoghurt, comprising the steps of:

[0034] (1) Yogurt base preparation:

[0035] Take 50 parts of raw milk and raise the temperature to 53°C, add 2 parts of whey protein powder to hydrate for 30 minutes, make the protein content not less than 3.6%, add 0.35 parts of compound stabilizer, 8 parts of white sugar, cut for 6 minutes, add the remaining 37 parts of raw milk were fixed to volume, then filtered and homogenized, the homogenization temperature was 65°C, the homogenization pressure was 18-20MPa, sterilized at 95°C for 300 seconds, and then cooled to 42°C after sterilization, according to the amount of 200DCU per ton Add starter and ferment at 42°C until the acidity reaches 75°T to obtain the yogurt base. Break the emulsion for 5 minutes, cool down to 20±2°C, turn over the tank, and wait for filling.

[0036] The compound stabilizer preferably consists of the following raw materials in parts by weight: gel...

Embodiment 2

[0045] A method for preparing black rice and white peach flavored yoghurt, comprising the steps of:

[0046] (1) The preparation of yogurt base material comprises the following steps:

[0047] Take 40 parts of raw milk and raise the temperature to 55°C, add 2 parts of whey protein powder to hydrate for 30 minutes, so that the protein content is not less than 3.6%, add 0.2 parts of compound stabilizer, 6 parts of white sugar, cut for 5 minutes, add 48 parts Raw milk is fixed to volume, then filtered and homogenized, the homogenization temperature is 60°C, the homogenization pressure is 18-20MPa, sterilized at 100°C for 300 seconds, after sterilization, the temperature is lowered to 40°C and the starter is added at an amount of 200DCU per ton , inoculated and fermented at 40°C, and the acidity was terminated at 80°T to obtain a yogurt base. Break the emulsion for 5 minutes, cool down to 20±2°C, turn over the tank, and wait for filling.

[0048] The compound stabilizer preferab...

Embodiment 3

[0057] A method for preparing black rice and white peach flavored yoghurt, comprising the steps of:

[0058] (1) Yogurt base preparation:

[0059] Add whey protein powder that is easily absorbed by the human body to no less than 87 parts of raw milk, add 6-10 parts of white sugar and 0.2-0.5 parts of compound stabilizer, mix well, and heat it at 95-100℃±2℃ , sterilized for 300 seconds, cooled to 40-44°C, added a starter at an amount of 200 DCU per ton, and fermented at 42°C until the acidity reached 75-80°T to obtain a yogurt base. Break the emulsion, cool down, turn over the tank, and wait for filling.

[0060] Take 30 parts of raw milk and raise the temperature to 53°C, add 2 parts of whey protein powder to hydrate for 30 minutes, so that the protein content is not less than 3.6%, add 0.5 parts of compound stabilizer, 6 parts of white sugar, cut for 10 minutes, add 60 parts Raw milk is fixed to volume, then filtered and homogenized, the homogenization temperature is 70°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com