Catalyst for the production of ethylbenzene from benzene and ethane

A catalyst, ethylbenzene technology, applied in molecular sieve catalysts, physical/chemical process catalysts, organic chemistry, etc., can solve the problems of low conversion rate of benzene and ethane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

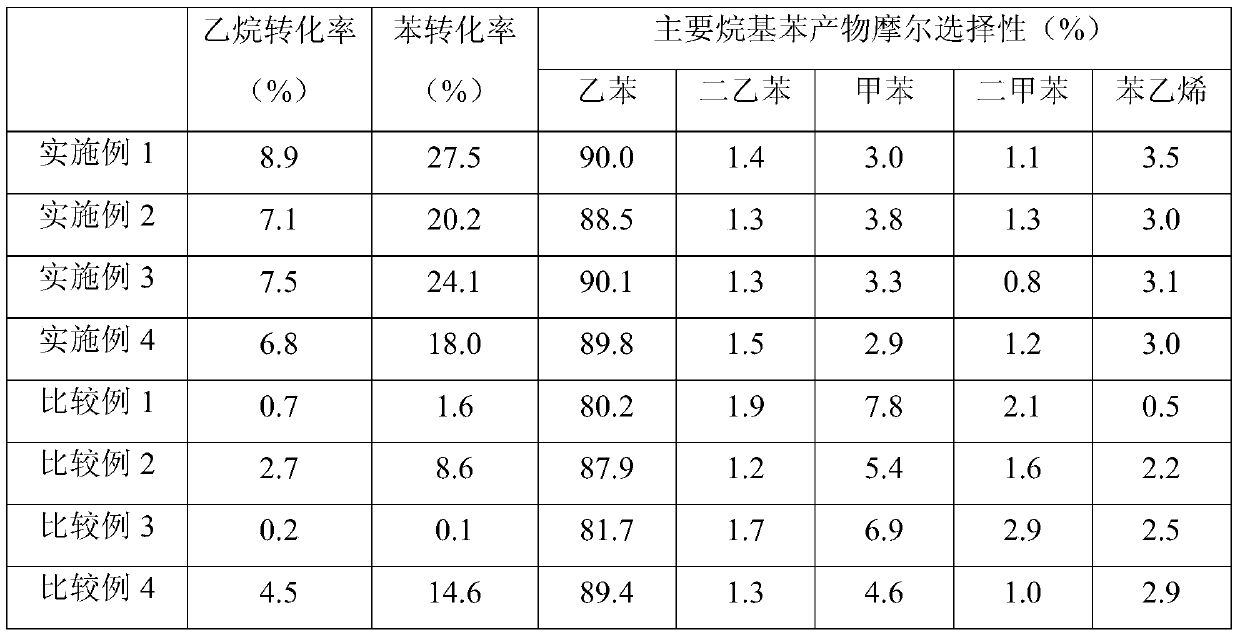

Examples

Embodiment 1

[0045] 1. Catalyst preparation

[0046] Weigh chloroplatinic acid containing 0.5g Pt (molecular formula is H 2 PtCl 6 ·6H 2 O), zinc nitrate equivalent to 0.7g ZnO (molecular formula is Zn(NO 3 ) 2 ·6H 2 O) and equivalent to 0.4g CeO 2 Cerium nitrate (molecular formula is Ce(NO 3 ) 3 ·6H 2O) Add it into 100mL deionized water, stir to make it all dissolve, and form a mixed solution; weigh 98.4g of hydrogen-type ZSM-5 molecular sieve (Si / Al molar ratio is 46), then add it to the above mixed solution, and soak for 3h , Dry at 100°C for 12h, and bake at 500°C for 2h.

[0047] The above product was tabletted and pulverized to 20-40 meshes, and a hydrogen-nitrogen mixed gas with a hydrogen volume content of 5% was used as a reducing agent, the reduction temperature was 350°C, and the reduction time was 1 hour to obtain a catalyst. The catalytic composition is shown in Table 1.

[0048] 2. Catalyst evaluation

[0049] The reaction of benzene and ethane to ethylbenzene is c...

Embodiment 2

[0051] 1. Catalyst preparation

[0052] Weigh chloroplatinic acid containing 0.5g Pt (molecular formula is H 2 PtCl 6 ·6H 2 O), zinc nitrate equivalent to 0.4g ZnO (molecular formula is Zn(NO 3 ) 2 ·6H 2 O) and equivalent to 0.7g CeO 2 Cerium nitrate (molecular formula is Ce(NO 3 ) 3 ·6H 2 O) Add it into 100mL deionized water, stir to make it all dissolve, and form a mixed solution; weigh 98.4g of hydrogen-type ZSM-5 molecular sieve (Si / Al molar ratio is 46), then add it to the above mixed solution, and soak for 3h , Dry at 100°C for 12h, and bake at 500°C for 2h.

[0053] The above product was tabletted and pulverized to 20-40 meshes, and a hydrogen-nitrogen mixed gas with a hydrogen volume content of 5% was used as a reducing agent, the reduction temperature was 350°C, and the reduction time was 1 hour to obtain a catalyst. The catalytic composition is shown in Table 1.

[0054] 2. Catalyst evaluation

[0055] The same method as in Example 1 was used to evaluate t...

Embodiment 3

[0057] 1. Catalyst preparation

[0058] Weigh chloroplatinic acid containing 0.5g Pt (molecular formula is H 2 PtCl 6 ·6H 2 O), zinc nitrate equivalent to 0.7g ZnO (molecular formula is Zn(NO 3 ) 2 ·6H 2 O) and equivalent to 0.4g La 2 o 3 Lanthanum nitrate (molecular formula La(NO 3 ) 3 ·6H 2 O) Add it into 100mL deionized water, stir to make it all dissolve, and form a mixed solution; weigh 98.4g of hydrogen-type ZSM-5 molecular sieve (Si / Al molar ratio is 46), then add it to the above mixed solution, and soak for 3h , Dry at 100°C for 12h, and bake at 500°C for 2h.

[0059] The above product was tabletted and pulverized to 20-40 meshes, and a hydrogen-nitrogen mixed gas with a hydrogen volume content of 5% was used as a reducing agent, the reduction temperature was 350°C, and the reduction time was 1 hour to obtain a catalyst. The catalytic composition is shown in Table 1.

[0060] 2. Catalyst evaluation

[0061] The same method as in Example 1 was used to evalua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com