Centrifuge tube and method for preparing platelet-rich plasma by using same

A technology of centrifuge tubes and centrifuges, applied in the direction of separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of complex extraction process and preparation method, low concentration of platelet-rich plasma, contamination of platelet-rich plasma, etc. No pollution, easy storage, easy storage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

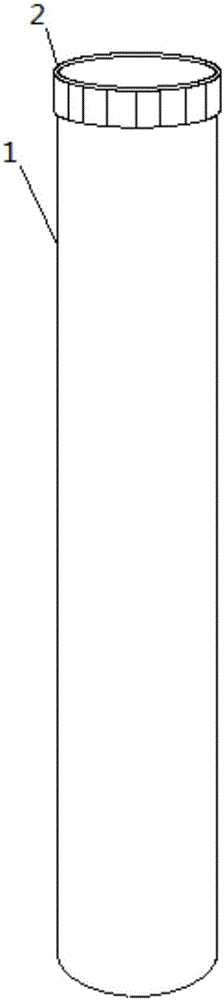

[0028] Such as figure 1 As shown, the centrifuge tube 1 is composed of a thin-walled hose with a sealed bottom. The centrifuge tube 1 has a slender tubular structure. The centrifuge tube 1 has a fixer 3 suitable for a centrifuge. Compatible with the outer surface of the structure, the fixer 3 includes a male head fixed with a socket convex key 4 and a female head fixed with an interface groove 5 , and the socket convex key 4 matches the interface groove 5 . There is a tube cover 2 on the top of the centrifuge tube 1, the inner diameter of the tube cover 2 is compatible with the outer diameter of the centrifuge tube 1, and the outer wall of the tube cover 2 is provided with anti-slip lines along the axial direction. Centrifuge tube 1 tube body has measuring scale.

Embodiment 2

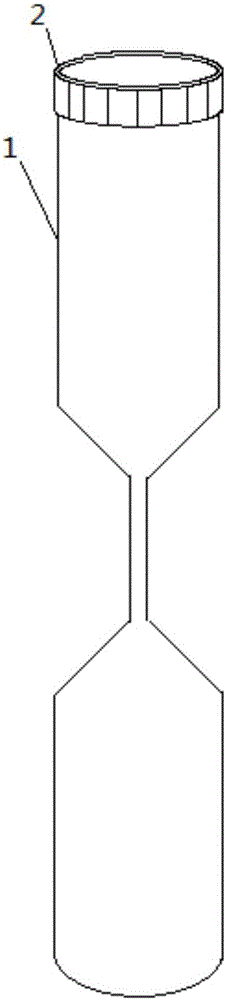

[0030] Such as figure 2 As shown, the centrifuge tube 1 is made of a thin-walled flexible tube with a sealed bottom. The centrifuge tube 1 is in a thin dumbbell-shaped structure. The dumbbell-shaped bottom of the centrifuge tube 1 is an arc bottom. The inner surface of the fixer 3 is adapted to the outer surface of the elongated structure of the centrifuge tube 1. The fixer 3 includes a male head fixed with the socket convex key 4 and a female head fixed with the interface groove 5, the socket convex key 4 and the interface groove 5 match. There is a tube cover 2 on the top of the centrifuge tube 1, the inner diameter of the tube cover 2 is compatible with the outer diameter of the centrifuge tube 1, and the outer wall of the tube cover 2 is provided with anti-slip lines along the axial direction. Centrifuge tube 1 tube body has measuring scale.

Embodiment 3

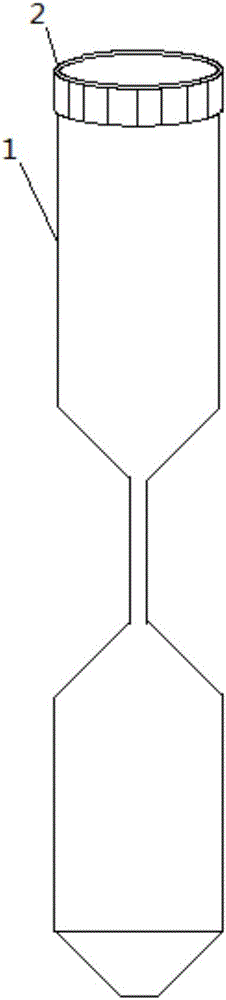

[0032] Such as image 3 As shown, the dumbbell-shaped bottom of centrifuge tube 1 is a conical bottom.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com