Device for monitoring coal position of coal mill through multiquadrant noise method

A coal mill and quadrant technology, applied in the direction of using electrical devices, measuring devices, and using electromagnetic means, can solve problems such as difficult to achieve precise control, signal distortion, and large noise, achieve high coal level monitoring accuracy, and solve signal distortion , good transient response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

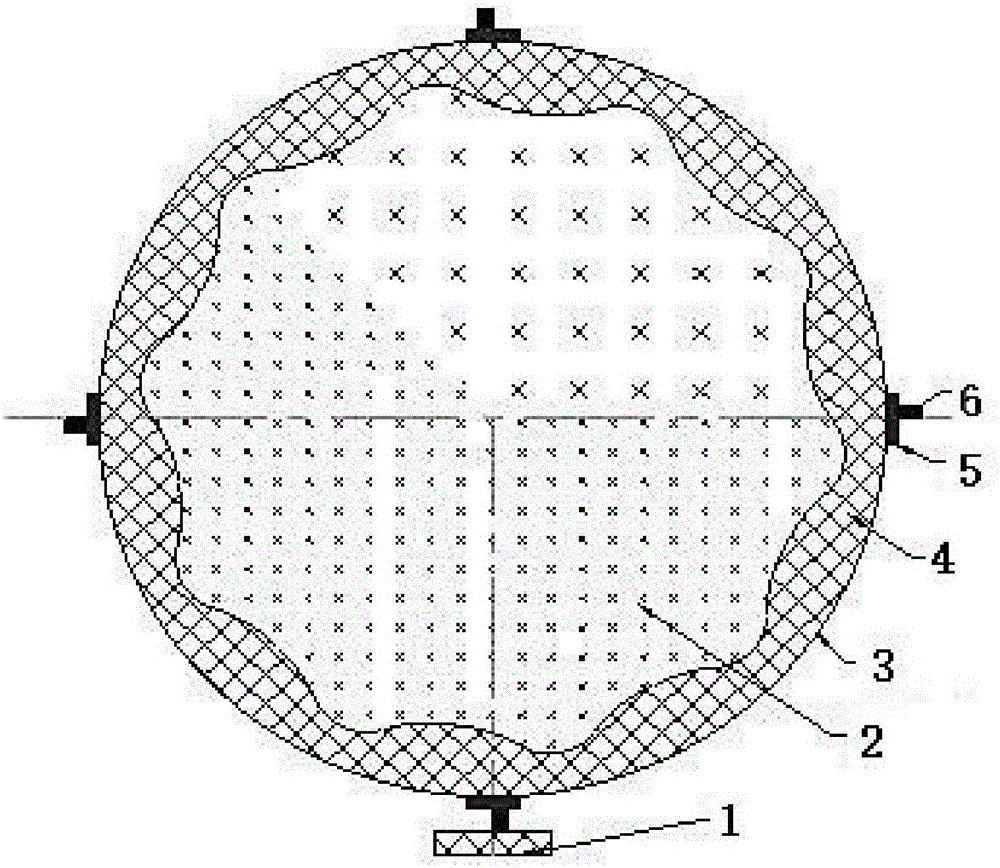

[0010] see figure 1 , a preferred embodiment of the present invention adopts the multi-quadrant noise method to monitor the coal mill coal level device, including a coal mill, four piezoelectric ceramic pickups 5 installed on the outside of the steel cylinder 3 of the coal mill, and an external processor 1. Taking the DTM380 / 830 coal mill as an example, the steel cylinder 3 of the coal mill has an effective diameter of 3.8m and an effective length of 8.3m. The inner wall of the steel cylinder 3 of the coal mill is laid with a wavy steel tile lining 4, The steel cylinder 3 is filled with a mixture 2 of steel balls and coal. The maximum volume of the steel balls filled in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com